Personally, I wouldn't choose to work with that torch as a starting-point - for a first build it's often better to start off with something tried and tested, and the rubberised feel isn't practical - it prevents heat transfer to the air. How were you planning on making the heatsink?

Many people start off with (and indeed, may continue to use) a laser built in one of these torches:

DealExtreme: $11.88 5W Luxeon Lumiled 3-AAA MXDL Flashlight

They are cheap, but for their price the quality is good, and they offer plenty of volume for the driver and heat-sink. Jayrob's builds are really impressive too.

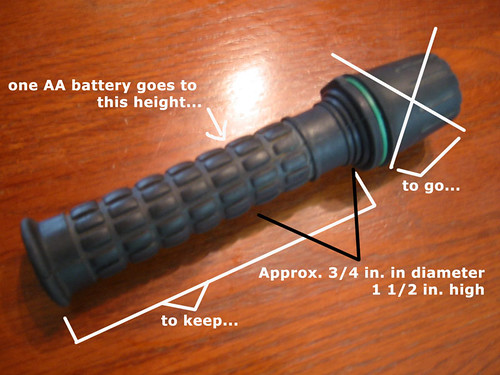

If you want to continue and use that torch, you'll either want to make the heat-sink for yourself, or measure the space available and work out a shape, then send the dimensions off to be made elsewhere. A "cut through" diagram is really useful once you've taken the required measurements, and will help you work out how you're going to use the space available.

In terms of the electronics, I'm afraid Fonduman's understanding is limited. Drivers can do two things - they can take too much voltage, but the right current, and waste the extra energy as heat (this is a linear regulator - LM317, 1117, "Groove", Rkcstr, and one of Lava's drivers), or they can take a higher or lower voltage, at a lower or higher current respectively, store the energy, then release it in a controlled way to the diode (this is a buck, boost, or buck-boost regulator - LM3410, "Spark", One/two of Lava's designs). Both methods have advantages and disadvantages (main ones being cost, current limit, stability, efficiency and temperature).

The reason you have to cut the supply rather than the output on one of Lava's drivers, as you described in #4, is essentially that the driver's process of storing and releasing the energy in a controlled way is vulnerable, and when there is no current on the output, it damages itself.