- Joined

- Dec 27, 2011

- Messages

- 2,062

- Points

- 48

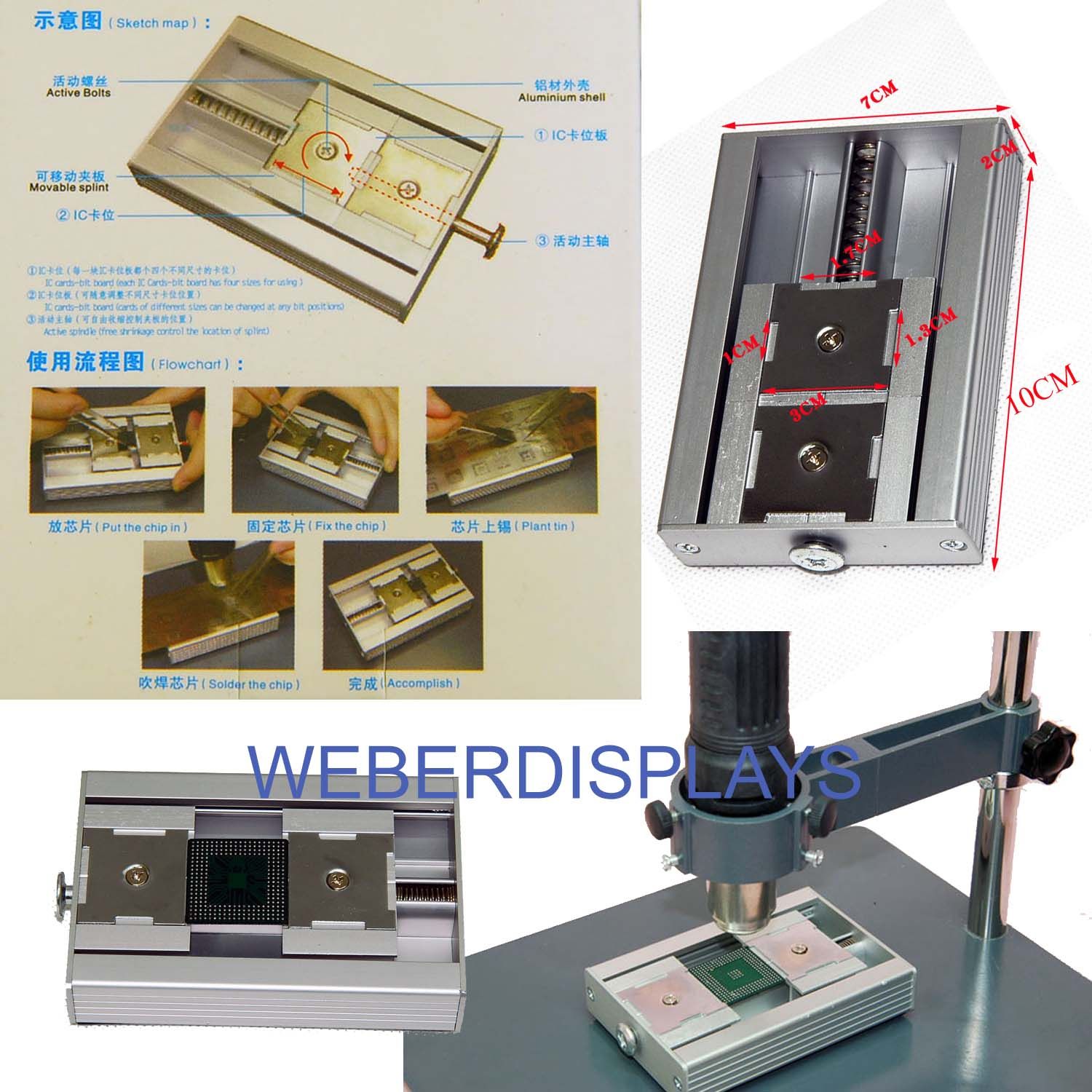

I've been working on some drivers, like laserluke's buck driver, which uses a very tough Surface Mount IC.

It looks daunting.

But this video is amazing and really helped me have the confidence to do some very small scale soldering.

It looks daunting.

But this video is amazing and really helped me have the confidence to do some very small scale soldering.