- Joined

- Oct 3, 2011

- Messages

- 899

- Points

- 0

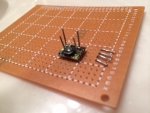

One of the biggest things I fret over when building my handhelds is setting up my drivers. Soldering wires to the driver just to be able to connect it to a battery or power source and driver dummy load is a real PITA. Un- soldering them and then cleaning the holes to accept new wire is also a PITA. I came up with a solution to this that has worked well so far. I think it's something that could be taken one step further and marketed to builders here. Basically all I did was take some solid silver wire (silver because I had it and it was the exact diameter of the holes in the drivers) and runn it through a PCB proto board in such a way that I can slip the driver down over the wires and connect my leads to my dummy load and PS? It works really well, very quick and simple solution to a problem that has given me much angst over the years.

What I envision is a single PCB with several slots where these "test prongs" are available to accept the most common drivers we use (X-drive, Flexdrives, Lava, mohgashm, etc) Additional there could be one or two "general purpose" slots with malleable prongs spaced in some general dimensions to accept drivers that are not the common ones. All of the prongs would have traces leading to common input and output terminals you could easily connect your PS and dummy load to. I also imagine going even a step further and including the dummy load and even a battery cage for one or two 3.7v cells on the board.

I have included some pics of my simplified prototype below. My hopes are that someone with the knowledge and skill to help me develop the PCB will step up and give me a hand with this. I will front the $$$ to get something like this produced if someone would be willing to help me. I'm not trying to make any profit on the forum, just bring something useful to the members. I suppose if someone were to help me and there was the need for them to get a little kickback on this we could discuss it. That's not really my interests but if it's the only way then we can talk. I was thinking a basic board with prongs should run somewhere around $10? Maybe less., that's my hopes anyways. I could be very niaeve to the costs of producing something like this, but based in some of the items I've seen around here that seems well within the ballpark. Something with a built in dummy load and battery cage might be $30-40? Not sure.

PM me if you can help or if you have general suggestions.

Jmillerdoc

What I envision is a single PCB with several slots where these "test prongs" are available to accept the most common drivers we use (X-drive, Flexdrives, Lava, mohgashm, etc) Additional there could be one or two "general purpose" slots with malleable prongs spaced in some general dimensions to accept drivers that are not the common ones. All of the prongs would have traces leading to common input and output terminals you could easily connect your PS and dummy load to. I also imagine going even a step further and including the dummy load and even a battery cage for one or two 3.7v cells on the board.

I have included some pics of my simplified prototype below. My hopes are that someone with the knowledge and skill to help me develop the PCB will step up and give me a hand with this. I will front the $$$ to get something like this produced if someone would be willing to help me. I'm not trying to make any profit on the forum, just bring something useful to the members. I suppose if someone were to help me and there was the need for them to get a little kickback on this we could discuss it. That's not really my interests but if it's the only way then we can talk. I was thinking a basic board with prongs should run somewhere around $10? Maybe less., that's my hopes anyways. I could be very niaeve to the costs of producing something like this, but based in some of the items I've seen around here that seems well within the ballpark. Something with a built in dummy load and battery cage might be $30-40? Not sure.

PM me if you can help or if you have general suggestions.

Jmillerdoc

Attachments

Last edited: