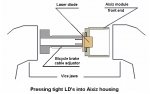

1st question- I remember reading a blog saying that a diode has to be fitted in an axis module "PROPERLY". Is there a certain way you have to put a SLD1239JL-54 16x diode inside the axis module to burn or do you just snap it in?

2nd question- After being told that a SLD1239JL-54 diode needs a heatsink to work at above 200 mA, this obviously means that high heat can damege a diode. Does that mean that just using a soldering iron to solder together the diode would hurt it? Is there some special way you have solder a diode?

3rd question- Does looking INDIRECTLY (not shining directly into your eye but standing like in this diagram below this next line and looking at it) harm your eyes if it is a laser that is more then 200 mA?

____________

Laser Beam

|<--------you

2nd question- After being told that a SLD1239JL-54 diode needs a heatsink to work at above 200 mA, this obviously means that high heat can damege a diode. Does that mean that just using a soldering iron to solder together the diode would hurt it? Is there some special way you have solder a diode?

3rd question- Does looking INDIRECTLY (not shining directly into your eye but standing like in this diagram below this next line and looking at it) harm your eyes if it is a laser that is more then 200 mA?

____________

Laser Beam

|<--------you