- Joined

- Oct 3, 2011

- Messages

- 899

- Points

- 0

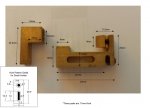

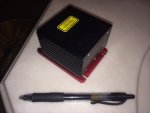

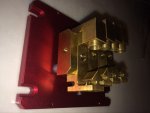

I just picked up four of these from a guy at PL. They come inside a small housing with a thick aluminum plate for the base. These assemblies are held onto a table built to be able to put a TEC under and contacting the base plate. Each of these are stacked next to each other side by side and fastened with a long bolt that goes through each one of these (through the slot at the bottom) that attaches them to the table. By slighly loosening this long bolt it allows these to slide past each other allowing a stair step configuration for mirrors, or without offset for dicros. It is infinitely adjustable here as well as the elevation of the diode holder block (up/down), and and the mirror/dicro mount works very much like a micro flex mount does. It holds a standard lens barrel like we use in all out handhelds here (threading is tighter though to allow stability in focus and beam position).

Planning to do some mixing experiments with it first and then once I get some hand held custom heat sinks made (similar to ARG's Tridentis) I plan to use these for mixing on a few handhelds. Planning on using one each on two different builds, and two of these on another. Not sure which colors I will be combining or knifing, that will be determined by the experimenting prior to gutting these out for the handhelds.

The biggest set back is they are direct press diode mounts set for 5.6mm diodes only. Once I've played with it a while I may have some machined for 9mm. Also may try to make a bezel for a 3.8mm diode to fit into a 9mm hole so I could use any of the three potentially.

It is an ambitious project but I've got time on my side. Check back someday and I will post some pics of the module in action and then eventually of a few mixing handhelds.

Thanks for looking! I mainly posted this here to have a place to refer the sink builder for pictures, and anyone else I may ask for assistance with mixing with these and building my handhelds. Hopefully some will find it interesting enough. The manufacturer of these is Edison, BTW.

Cheers!

Planning to do some mixing experiments with it first and then once I get some hand held custom heat sinks made (similar to ARG's Tridentis) I plan to use these for mixing on a few handhelds. Planning on using one each on two different builds, and two of these on another. Not sure which colors I will be combining or knifing, that will be determined by the experimenting prior to gutting these out for the handhelds.

The biggest set back is they are direct press diode mounts set for 5.6mm diodes only. Once I've played with it a while I may have some machined for 9mm. Also may try to make a bezel for a 3.8mm diode to fit into a 9mm hole so I could use any of the three potentially.

It is an ambitious project but I've got time on my side. Check back someday and I will post some pics of the module in action and then eventually of a few mixing handhelds.

Thanks for looking! I mainly posted this here to have a place to refer the sink builder for pictures, and anyone else I may ask for assistance with mixing with these and building my handhelds. Hopefully some will find it interesting enough. The manufacturer of these is Edison, BTW.

Cheers!