- Joined

- Sep 4, 2020

- Messages

- 21

- Points

- 3

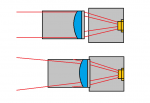

Hello All, ok so first time with a G8 lens here and im coming to all of you with a little bit of displeasure. The tube seems so short! By the time i get the beam focused how i want, i only have one spin left in the barrel and then it falls off. Has anyone came up with a solution for this? Does anyone make some type of adapter or extender or a better tube? On top of that it is so loose. Has anyone came up with any solutions for the loose thread pitch? Lots of play... too much for my liking.

Also i broke my G8 :/ by over tightening it.

Also i broke my G8 :/ by over tightening it.