- Joined

- Apr 4, 2016

- Messages

- 3

- Points

- 0

Hello Everyone,

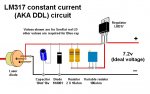

I've been researching the DDL laser driver and would like some help in understanding the circuit. I intent to use it to build a 690nm laser with a 10mW output (I'd like to start small and happen to have this diode around), preferably using 5 volts. I figured I'd start by stating what I do understand before going onto my question. If I'm posting this in the wrong forum I apologize. I'm new here and the amount of content is overwhelming.

Concerning the components of the DDL circuit attached below, I understand that:

-The diode is to protect the laser diode in case the batteries are placed in reverse

-The Capacitor is to smooth out the current going into the laser diode

-The potentiometer is to adjust the resistance of the system ( the greater the resistance, the less the current).

Additionally, I understand that you can test the current output by using a dummy load instead of the laser driver if you do not want to burn it (other picture). the diodes are chosen to have a voltage drop close or at the operating voltage of the laser diode. The 1-ohm resistor is to use Ohm's law to figure out the current flowing thru it.

My questions are:

-Is there a calculation for determining the capacitance to use?

-Why do we have fixed resistors if we have a potentiometer?

-How do we calculate the fixed resistor values?

-When choosing a voltage to supply to the LM317, is it 3V + Operating voltage of the laser driver? I'm not sure why 3V, but from what I can understand the LM317 requires 3V.

Again, I apologize if I've done something wrong and thank you for your time.

I've been researching the DDL laser driver and would like some help in understanding the circuit. I intent to use it to build a 690nm laser with a 10mW output (I'd like to start small and happen to have this diode around), preferably using 5 volts. I figured I'd start by stating what I do understand before going onto my question. If I'm posting this in the wrong forum I apologize. I'm new here and the amount of content is overwhelming.

Concerning the components of the DDL circuit attached below, I understand that:

-The diode is to protect the laser diode in case the batteries are placed in reverse

-The Capacitor is to smooth out the current going into the laser diode

-The potentiometer is to adjust the resistance of the system ( the greater the resistance, the less the current).

Additionally, I understand that you can test the current output by using a dummy load instead of the laser driver if you do not want to burn it (other picture). the diodes are chosen to have a voltage drop close or at the operating voltage of the laser diode. The 1-ohm resistor is to use Ohm's law to figure out the current flowing thru it.

My questions are:

-Is there a calculation for determining the capacitance to use?

-Why do we have fixed resistors if we have a potentiometer?

-How do we calculate the fixed resistor values?

-When choosing a voltage to supply to the LM317, is it 3V + Operating voltage of the laser driver? I'm not sure why 3V, but from what I can understand the LM317 requires 3V.

Again, I apologize if I've done something wrong and thank you for your time.