cbrian4

0

- Joined

- Dec 24, 2007

- Messages

- 309

- Points

- 0

Alright so I have been away for quite a while and decided to check back recently and found out about these super powerful blue diodes. And since I have always wanted a blue laser, I couldn't resist doing another build. However, I wanted something unique and different that was also portable. I see people use flashlights all the time and decided against it since I had the ability to make my own host.

Here is my build:

I chose brass because I really like how it looks, its easy to work with, and because it has relatively good thermal conductivity. Plus brass polishes up real nice

Here is the headpiece before polishing

And after

This was achieved by sanding with 400 grit, then 600, and finally 1200. After sanding, i used a dremel buffing wheel with green compound.

Tail piece

Middle tube with engraving

The threads on this are pretty fine, from trough to peak we're talking

.01inches

Completely assembled host minus guts

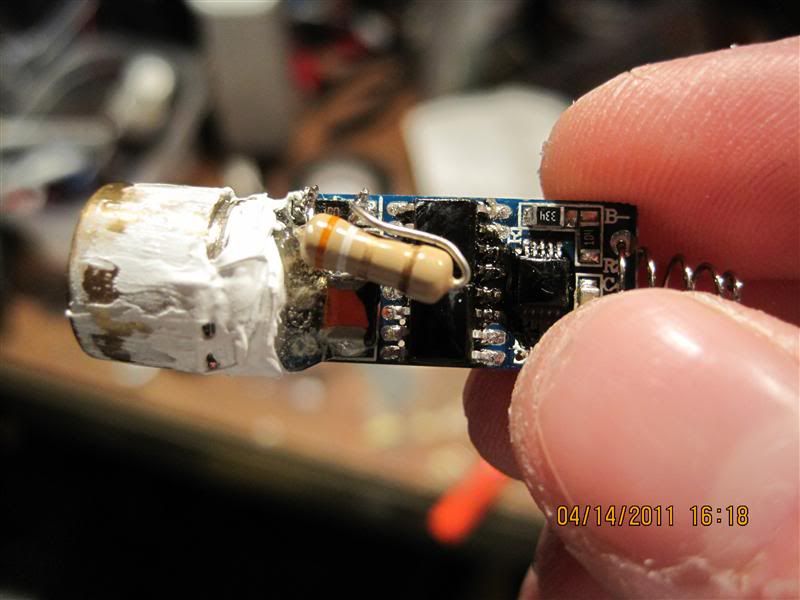

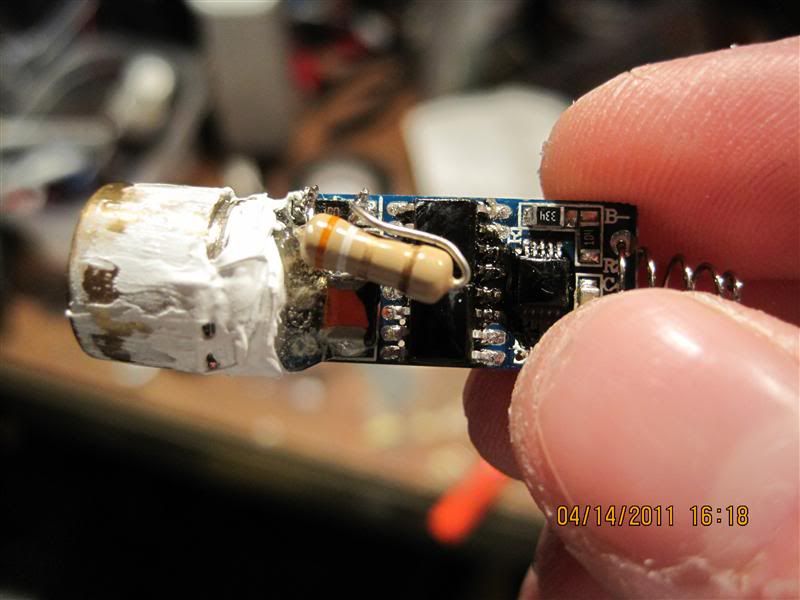

I would have went with a flexdrive but they are extremely scarce right now :cryyy: I ended up going with that aixiz/olike driver which, as most will already know, is not great. I do really like that the positive input is on the diode end of the board, which alows you to solder it to the case pin of the diode.

I modified it by soldering a 3.9 ohm resistor in parallel with R4 and by doing this I got a current draw from the battery of 1.55A with a freshly charged 14500. This should deliver about 1.1A to the diode. I soldered the board up to the diode which I had already pressed into the aixiz module, and then hit it with epoxy to make sure it would stay. The white stuff is thermal compound. (Don't worry, Its not as much as it looks.)

I originally machined a copper heatsink but ruined it in the mill by accident and didn't have any more :cryyy: so I went with aluminum.

Driver diode module assembled into heatsink

I then applied some thermal compound to the inside of the head piece and slipped the heatsink module into the head. I am using an aixiz 445 glass lens.

Final assembly was a snap, just threaded the battery tube on and loaded up a 14500 battery. Again, this is a case positive laser.

Completely assembled and ready to go!

Beamshots! These are non-enhanced shots with no smoke or prolonged exposure.

Overall I am very pleased with this laser, I love the looks and its very compact. I really like how clean the install is with this driver, it may not be the best in performance, but is very easy on the build side and is wire free. I hope that other, higher quality case positive drivers will pop up in the near future.

The cooling is great on this unit since the whole thing is made of metals that are pretty thermally conductive. I still keep it to a short duty cycle cause the driver gets hot.

Unfortunately I do not have an LPM but my guess is its pretty close to 1W especially if I were to use a G-1 lens.

Thoughts, comments, questions?

Thanks for viewing!

Here is my build:

I chose brass because I really like how it looks, its easy to work with, and because it has relatively good thermal conductivity. Plus brass polishes up real nice

Here is the headpiece before polishing

And after

This was achieved by sanding with 400 grit, then 600, and finally 1200. After sanding, i used a dremel buffing wheel with green compound.

Tail piece

Middle tube with engraving

The threads on this are pretty fine, from trough to peak we're talking

.01inches

Completely assembled host minus guts

I would have went with a flexdrive but they are extremely scarce right now :cryyy: I ended up going with that aixiz/olike driver which, as most will already know, is not great. I do really like that the positive input is on the diode end of the board, which alows you to solder it to the case pin of the diode.

I modified it by soldering a 3.9 ohm resistor in parallel with R4 and by doing this I got a current draw from the battery of 1.55A with a freshly charged 14500. This should deliver about 1.1A to the diode. I soldered the board up to the diode which I had already pressed into the aixiz module, and then hit it with epoxy to make sure it would stay. The white stuff is thermal compound. (Don't worry, Its not as much as it looks.)

I originally machined a copper heatsink but ruined it in the mill by accident and didn't have any more :cryyy: so I went with aluminum.

Driver diode module assembled into heatsink

I then applied some thermal compound to the inside of the head piece and slipped the heatsink module into the head. I am using an aixiz 445 glass lens.

Final assembly was a snap, just threaded the battery tube on and loaded up a 14500 battery. Again, this is a case positive laser.

Completely assembled and ready to go!

Beamshots! These are non-enhanced shots with no smoke or prolonged exposure.

Overall I am very pleased with this laser, I love the looks and its very compact. I really like how clean the install is with this driver, it may not be the best in performance, but is very easy on the build side and is wire free. I hope that other, higher quality case positive drivers will pop up in the near future.

The cooling is great on this unit since the whole thing is made of metals that are pretty thermally conductive. I still keep it to a short duty cycle cause the driver gets hot.

Unfortunately I do not have an LPM but my guess is its pretty close to 1W especially if I were to use a G-1 lens.

Thoughts, comments, questions?

Thanks for viewing!

Last edited: