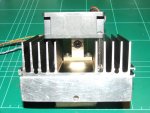

I have built a little test platform for my projector build, using a 1W 445 fitted to a brass mount from Dave at PL, with a Glass AR lens. I was running this diode at 1250mA at max modulation, although now I have decided to limit that to 1000mA.

The beam in the image is defocused simply because when focused whatever it points at catches fire lol.

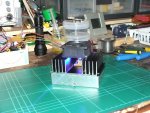

I am still to determine the final labbie build for this diode and my reds.

The beam in the image is defocused simply because when focused whatever it points at catches fire lol.

I am still to determine the final labbie build for this diode and my reds.