Hello all, this is my first post about my first DIY project.

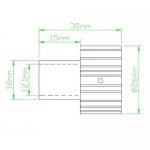

I have bought a 2W Copper 445nm M140 Blue Laser Module W/X-Drive & 405-G-2 Glass Lens.

I have still not received my heatsink so I have test it 1sec and let it cool down 1min for each tests.

My question is : is it possible to get a slim sharp "infinite" straight beam with this setting ?

Because for now, I have not find the right "focus" of the lense.

The beam is always a "cone".

Thank you for your reply.

I have bought a 2W Copper 445nm M140 Blue Laser Module W/X-Drive & 405-G-2 Glass Lens.

I have still not received my heatsink so I have test it 1sec and let it cool down 1min for each tests.

My question is : is it possible to get a slim sharp "infinite" straight beam with this setting ?

Because for now, I have not find the right "focus" of the lense.

The beam is always a "cone".

Thank you for your reply.

Last edited: