Asherz

0

- Joined

- Jan 18, 2009

- Messages

- 1,623

- Points

- 0

Well, basically I've been playing with the idea of a DIY TEC cooled labby for a few days, and after seeing jayrobs icebox tutorial the idea became more than feasible.

I would like to go one step further and get a custom aluminum lab heatsink milled on a CNC router, so that it's all ready for the different componants I want to include.

- Current reading panel meter

- Adjustable pot to change diode current

- Key switch

- small fan

- TEC cooled heatsink

- Direct press diode heatsink

- adjustable focus

- Unlimited duty cycle

The whole idea of this is so that I can pop in for example a LOC into the removable heatsink and then run it way above the recommended current for extra high outputs whist not sacrificing life span.

I have a proposed design and as long as it's not too expensive to get machined (probably going to be) I'll probably go a head with the project, I just need to sort out the electronics to go in it, such as 3 LM317 based drivers, 1 for the diode and 1 for each TEC.

It would be run of a DC plug from the wall socket, it's just a matter of working out how much power I'm going to need and buying the appropriate plug.

Design:

Fan needs to be moved down slightly

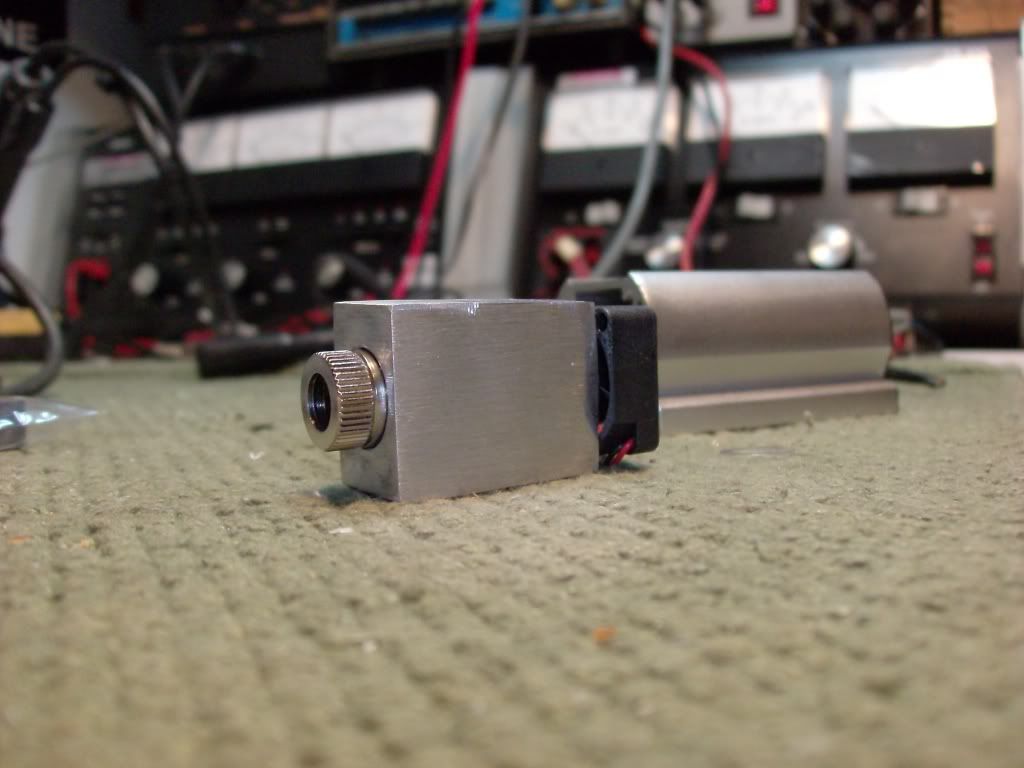

give an idea of scale

The main reason it's pretty large is too allow for enough width at the back to hold the 79mm wide panel meter to read the current.

Advice:

I know this is an overkill, but realistically with this much cooling would it be possible to push a LOC, or a GGW for example much higher than a heavily heats-sinked host? any one got any ideas on numbers?

This project would be really cool if it happens, but Im going to need to find a CNC machinist so if there's anyone out there who thinks they can get 1 or 2 of these made for a good price say so

comments?

If this doesn't work out then I will definitly be giving Jayrobs Ice box tutorial ago with some different components.

I would like to go one step further and get a custom aluminum lab heatsink milled on a CNC router, so that it's all ready for the different componants I want to include.

- Current reading panel meter

- Adjustable pot to change diode current

- Key switch

- small fan

- TEC cooled heatsink

- Direct press diode heatsink

- adjustable focus

- Unlimited duty cycle

The whole idea of this is so that I can pop in for example a LOC into the removable heatsink and then run it way above the recommended current for extra high outputs whist not sacrificing life span.

I have a proposed design and as long as it's not too expensive to get machined (probably going to be) I'll probably go a head with the project, I just need to sort out the electronics to go in it, such as 3 LM317 based drivers, 1 for the diode and 1 for each TEC.

It would be run of a DC plug from the wall socket, it's just a matter of working out how much power I'm going to need and buying the appropriate plug.

Design:

Fan needs to be moved down slightly

give an idea of scale

The main reason it's pretty large is too allow for enough width at the back to hold the 79mm wide panel meter to read the current.

Advice:

I know this is an overkill, but realistically with this much cooling would it be possible to push a LOC, or a GGW for example much higher than a heavily heats-sinked host? any one got any ideas on numbers?

This project would be really cool if it happens, but Im going to need to find a CNC machinist so if there's anyone out there who thinks they can get 1 or 2 of these made for a good price say so

comments?

If this doesn't work out then I will definitly be giving Jayrobs Ice box tutorial ago with some different components.

Last edited: