- Joined

- Aug 30, 2008

- Messages

- 6,891

- Points

- 83

you can also do a simple experiment to test ho effective it is.

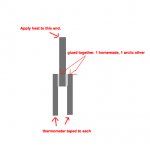

get 3 flat pieces of aluminum, and glue two pieces on each side of a single piece.

glue 1 with the homemade glue, and the other with arctic silver. tape a thermometer to each prong, and then apply heat to the first piece.

whichever piece heats up more, it's transferring more heat through the glue and into the metal.

Here is a picture.

this would also be helpful for finding out what ratio of epoxy/powder works best

get 3 flat pieces of aluminum, and glue two pieces on each side of a single piece.

glue 1 with the homemade glue, and the other with arctic silver. tape a thermometer to each prong, and then apply heat to the first piece.

whichever piece heats up more, it's transferring more heat through the glue and into the metal.

Here is a picture.

this would also be helpful for finding out what ratio of epoxy/powder works best

Attachments

Last edited: