rhd

0

- Joined

- Dec 7, 2010

- Messages

- 8,475

- Points

- 0

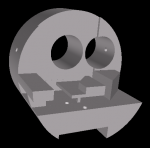

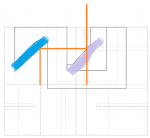

Btw, Do you have any idea's for a retaining "plate" that can be placed between the heatsink and host walls that would would be either polished aluminum or just a piece of black plastic with an aperature hole? That would ovbiously ensure dust protection and better looks. You probably could also glue a high transmitting lens which would make the whole thing water and dust proof (If the rest of your host is waterproof)

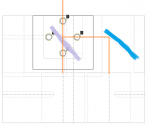

I guess my final recommendation would be using a host like the nf-009 or similar which allows for more headroom which would also let you move the two holes a bit to the side so the output isn't exiting the host completely to one side.

Yes, probably a simple circular disc with a hole drilled through it would work. We could even combine that either with a smaller window underneath, or literally sandwich it entirely on top of the stock glass flashlight window (would avoid needing to affix the glass to the metal). That said, this is something that I think we'd be better off getting a machinist in the forum to do. I don't think CNC is required, and it would substantially push up the costs even given the simplicity, if I sourced it through eMachineShop also.

Regarding the NF-009, I looked at that, and my initial take is that while it has a larger diameter, it doesn't really allow for additional height. Height is what we may need a bit more of. The additional diameter could allow for more of a centered output though - I hadn't thought of that. It might also allow us to hollow out the unused side of the combiner, and turn it into a pill for driver heat-sinking.

The other thing I'll probably do is create a simple PCB for a dual-diode driver based on dual STCS1 or LM1117s.

RHD, I like how you started off here by copying the Chinese. (Vs how it usually goes)

(You've enhanced the design since but...) -- turnabout is *such* fair play in this situation

I know, I was conscious of the humor in that as well.

- and also conscious of not wanting to upset... anyone