- Joined

- Jul 29, 2014

- Messages

- 100

- Points

- 18

I think it can be used, but why not use similar mount as used in arctos?

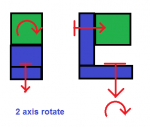

The most important is to make the holes for fi 12 modules in the seame height, and adjustment you do with the knife mirror, not the diode itself. With diode the only important thing is to have the possiblity of turning it.

But your idea is also fine, when you make fi12 holes you will have a lot more adjustment. I have the same parts in one of my machines, sadly they are really loose, and setting them in proper position is easy but how to make them not move later?

The most important is to make the holes for fi 12 modules in the seame height, and adjustment you do with the knife mirror, not the diode itself. With diode the only important thing is to have the possiblity of turning it.

But your idea is also fine, when you make fi12 holes you will have a lot more adjustment. I have the same parts in one of my machines, sadly they are really loose, and setting them in proper position is easy but how to make them not move later?