- Joined

- Apr 2, 2009

- Messages

- 356

- Points

- 0

I am going to be building a spiro and I want it to be a non-portable high quality unit. I would like it to produce a wide range of patterns(for a spiro anyways) and a have large projected size on the wall. To get a larger size projection would need to increase the angle of the mirror on the motor? If so should I do that on both mirrors or just that last? EDIT: I think using larger mirrors that are slightly more off center allows for the ability create larger patterns.

Is there a big advantage to going to a 3 mirror spiro over 2 mirrors? EDIT: just found you tube video that showed a 3 mirror, think thats the ways to go for a non-portable spiro.

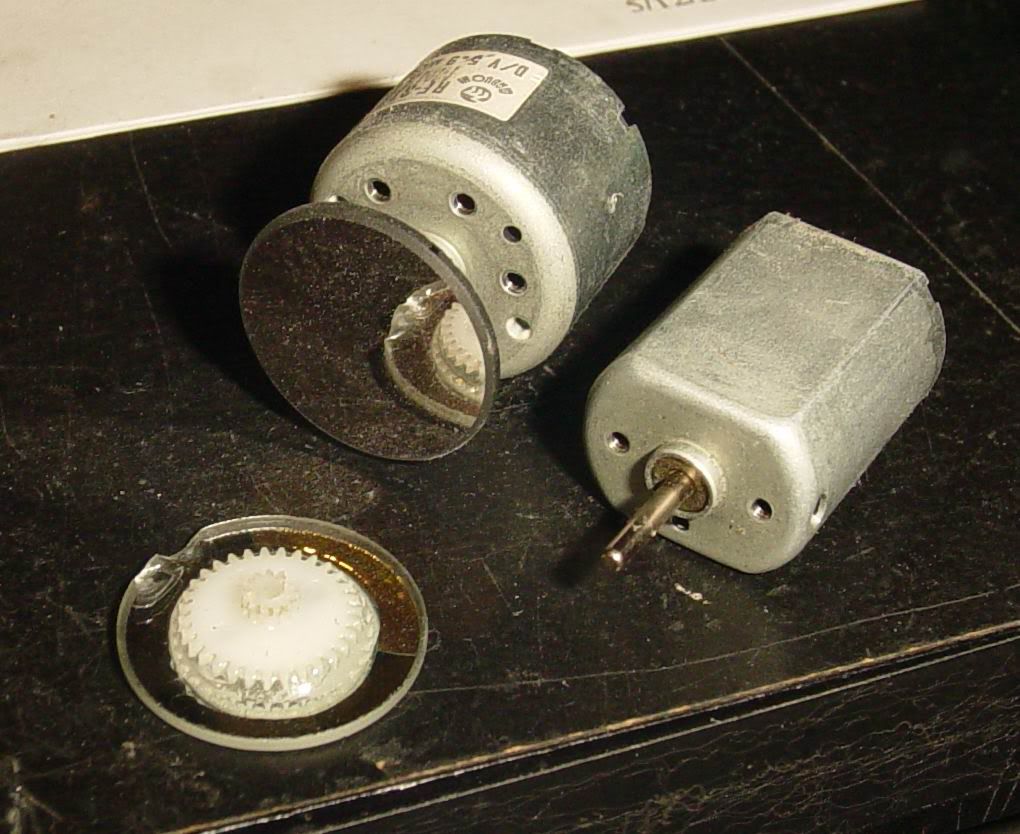

I am going to order the motors and pots from an electronics site so i need a ballpark on what would be good motors for this project. i know there is a lot of other threads on spiros but most people are putting them in portable packages so they are using tiny motors. Is there any advantage to having high RPM motors(besides the cool sound)? I am going with a 100 ohm pot i guess because thats what is suggested.

EDIT: i guess all i need answered is what type of motors should i order.

Is there a big advantage to going to a 3 mirror spiro over 2 mirrors? EDIT: just found you tube video that showed a 3 mirror, think thats the ways to go for a non-portable spiro.

I am going to order the motors and pots from an electronics site so i need a ballpark on what would be good motors for this project. i know there is a lot of other threads on spiros but most people are putting them in portable packages so they are using tiny motors. Is there any advantage to having high RPM motors(besides the cool sound)? I am going with a 100 ohm pot i guess because thats what is suggested.

EDIT: i guess all i need answered is what type of motors should i order.

Last edited: