- Joined

- May 2, 2012

- Messages

- 151

- Points

- 18

Hi guys!

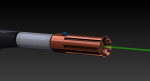

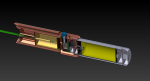

After measuring the power of my green Lasever module, i decided it deserves a new selfbuilt host. I just measured all dimensions of module and driver. I want to drive it with a 26650 battery, since it draws 4,5A at 3,2V. So with higher Voltage its even more. I tried it shortly with 3,5V and it was already over 6A of draw. Therefore i want to change it from the 18650 to the 26650 batt.

I am going to make the new host completly out of copper, because of the better heat conduction. One thing i dont understand: the module is made out of brass, wich conducts heat only half as good as aluminum and only quarter as good as copper. Is there a reason for using brass? The driver has some electrical parts wich need to be cooled. I want to get them fitted to the copper host. For this i am going do design the host in 3D CAD.

Now my questions:

-Is there a recommendation for a good and small keyswitch wich can take over 6A of current draw?

-I´d like to be able of closing the front end of the laser like the Herkules lasers, with turning the front tip. http://www.dragonlasers.com/catalog/photos/800/h1.jpg

Are these systems available?

-I want to integrate the focusing in a way, that i can change it from the outside. Don´t have a good concept yet.

Greetings,

numquamretro

After measuring the power of my green Lasever module, i decided it deserves a new selfbuilt host. I just measured all dimensions of module and driver. I want to drive it with a 26650 battery, since it draws 4,5A at 3,2V. So with higher Voltage its even more. I tried it shortly with 3,5V and it was already over 6A of draw. Therefore i want to change it from the 18650 to the 26650 batt.

I am going to make the new host completly out of copper, because of the better heat conduction. One thing i dont understand: the module is made out of brass, wich conducts heat only half as good as aluminum and only quarter as good as copper. Is there a reason for using brass? The driver has some electrical parts wich need to be cooled. I want to get them fitted to the copper host. For this i am going do design the host in 3D CAD.

Now my questions:

-Is there a recommendation for a good and small keyswitch wich can take over 6A of current draw?

-I´d like to be able of closing the front end of the laser like the Herkules lasers, with turning the front tip. http://www.dragonlasers.com/catalog/photos/800/h1.jpg

Are these systems available?

-I want to integrate the focusing in a way, that i can change it from the outside. Don´t have a good concept yet.

Greetings,

numquamretro

Attachments

Last edited: