rhd

0

- Joined

- Dec 7, 2010

- Messages

- 8,475

- Points

- 0

Keep in mind that the linear 1085 based "DDL" style drivers we use to drive 1.8A 445nm diodes are basically using two resistors to get a voltage drop reference of 1.25V. That's a bit above 1 W of dissipation, and those are typically 2512 resistors rated for 1W (maybe 2W).

The guys I linked above (2728 package), have 2.5X the surface area of a 2512 package resistor, and they're being required to drop a bit less heat too. As weird as it sounds, you can actually heatsink them too. The way I've laid them out on this board, you can arctic silver one thin aluminum strip across all of them (between the contacts of course) and that will raise the elevation enough that you could then stick a tiny heatsink across all 4 at once, without any risk of shorting. That said, I really don't think it will be needed based on what I've observed with much smaller SMD resistors at a similar power dissipation (inside closed hosts as well).

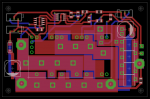

Here's a revision. Additions, other than the resistor update, are a ton of beefier planes for the current to travel. Now that I have a way to drive one, I'll probably grab a diode bar at some point. Once I do, I'll actually get these PCBs made. I need to do 10x at a time, so if anyone else wants one, they're more than welcome to it (that is, with Mosc's permission).

The one thing I would add before making this, would be the ENABLE feature. I'll have to wrap my mind around Mosc's suggestion as to how to implement it, and see if it can be worked in without requiring any major re-routeing of the board.

The guys I linked above (2728 package), have 2.5X the surface area of a 2512 package resistor, and they're being required to drop a bit less heat too. As weird as it sounds, you can actually heatsink them too. The way I've laid them out on this board, you can arctic silver one thin aluminum strip across all of them (between the contacts of course) and that will raise the elevation enough that you could then stick a tiny heatsink across all 4 at once, without any risk of shorting. That said, I really don't think it will be needed based on what I've observed with much smaller SMD resistors at a similar power dissipation (inside closed hosts as well).

Here's a revision. Additions, other than the resistor update, are a ton of beefier planes for the current to travel. Now that I have a way to drive one, I'll probably grab a diode bar at some point. Once I do, I'll actually get these PCBs made. I need to do 10x at a time, so if anyone else wants one, they're more than welcome to it (that is, with Mosc's permission).

The one thing I would add before making this, would be the ENABLE feature. I'll have to wrap my mind around Mosc's suggestion as to how to implement it, and see if it can be worked in without requiring any major re-routeing of the board.