- Joined

- Apr 5, 2009

- Messages

- 33

- Points

- 0

I'm looking for a labby- style enclosure suitable to house an LPC-815 LOC mounted into the side panel with a focusing module. I'm planning on pinning the axis module in place using two dark horse black anodized heatsinks, one on the outside of the enclosure, one on the inside, with the axis module running through them both. The enclosure should also have room for a small cpu cooling fan and the two DDL-style drivers for the fan and LD.

Is it necessary to use the case as a heatsink in this scenario? Or will the two dark horse heatsinks be enough? I plan on giving the LOC LD about 420mA.

This should make the difference between using black abs plastic, or aluminum. Any suggestions for good enclosures?

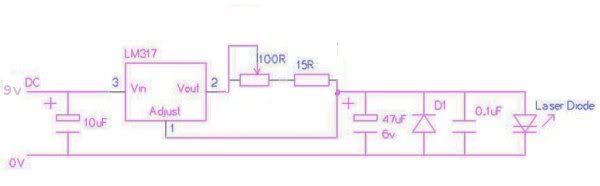

If I run a ddl style lm317- based driver between the 300mA-450mA range, is it necessary to heatsink the IC package?

Is it necessary to use the case as a heatsink in this scenario? Or will the two dark horse heatsinks be enough? I plan on giving the LOC LD about 420mA.

This should make the difference between using black abs plastic, or aluminum. Any suggestions for good enclosures?

If I run a ddl style lm317- based driver between the 300mA-450mA range, is it necessary to heatsink the IC package?