- Joined

- Feb 25, 2010

- Messages

- 1,643

- Points

- 113

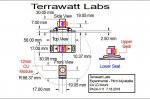

Well.....Just a little concept drawing I did. We can have it all !!

With a standard LSP style mount....Yaw adjustability is available....but not Pitch.

See Drwg. PALDM-V7 attached. This might be one way to use a three ( 3) piece unit to achieve Pitch Adjustability !!! Good solid contact at all interfaces. About +/- 2mm travel....More than enough Pitch translation !!!

Outer slots in the lower seat give Yaw control. Upper slots provide travel and set for the upper seat.

Just a thought....Until I machine one.....I will not be sure the design is feasible !!!

Always thnk'in !!! Never seen one like this before. Any commercial manufacture that makes this.....you're welcome....Hmmm....not to humble hey !!!

Oh Well....It might work !!!

CDBEAM :eg::eg::eg:

With a standard LSP style mount....Yaw adjustability is available....but not Pitch.

See Drwg. PALDM-V7 attached. This might be one way to use a three ( 3) piece unit to achieve Pitch Adjustability !!! Good solid contact at all interfaces. About +/- 2mm travel....More than enough Pitch translation !!!

Outer slots in the lower seat give Yaw control. Upper slots provide travel and set for the upper seat.

Just a thought....Until I machine one.....I will not be sure the design is feasible !!!

Always thnk'in !!! Never seen one like this before. Any commercial manufacture that makes this.....you're welcome....Hmmm....not to humble hey !!!

Oh Well....It might work !!!

CDBEAM :eg::eg::eg:

Attachments

Last edited: