***************This is the latest " Breaking news"**********************************

************************Modified January 2, 2009*********************************

Ok, a quick update: I'm going to get these made professionally at a machine shop as I don't have the time to make a suitably sized batch while at university. I'm going to get 40 MXDL style made and 10 Dorcy's made

As the first batch is in limited quantities - get your name down now, as they will be sent on a first-come, first-served basis.

Pm Daniel or Catmandoo and we will list the names in this thread, Paypal is the prefered payment method.

Both the Dorcy and the MXDL will sell for $25 each, with larger bulk discounts available upon request. As this is the first batch, I'll throw in a free tube of thermal compound with each one sold! How's that for added value?

I'm going to roadtest another one shortly, as soon as my next lot of diodes arrive, with a long open can red burner in, and really turn up the current, to make one smokin' laser. I'll whack an Aixiz glass lens in, and see how the duty cycle goes at high currents. I'm hoping for 300mW+ at 100% duty cycle *fingers crossed*

MXDL host that these are designed for http://www.dealextreme.com/details.dx/sku.4171

Here is the Dorcy tactical

http://www.amazon.com/Dorcy-41-4290...ref=sr_1_1?ie=UTF8&s=hi&qid=1230945426&sr=8-1

The scheduled release date is early to mid february so start ordering early if you want in on the first batch !

Daniel

Here is the list of orders.

Lasersbee, 2, MXDL

Hi All,

Over Christmas Greg (CMD) and myself have been exchanging ideas for a heatsink in which the diode mounts directly into, thus providing the best possible cooling in a stylish package, tailored to fit specific hosts. We've both had this idea for a while, but it's only really come into fruition in the last week or so.

*Latest Version: V0.4*

*This initial post has been updated to reflect latest design*

The heatsinks will be hand made from solid aircraft-grade aluminium bar (6082 T6), and a light brushed finished applied.

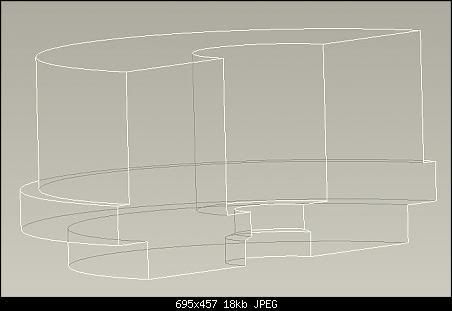

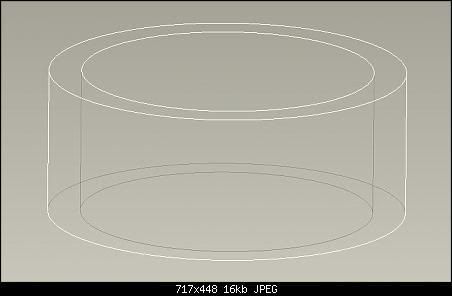

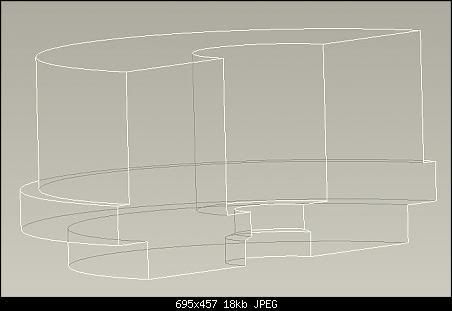

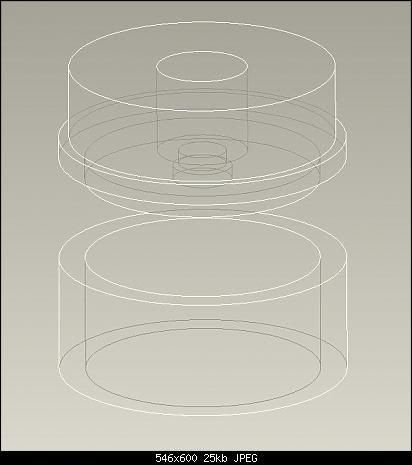

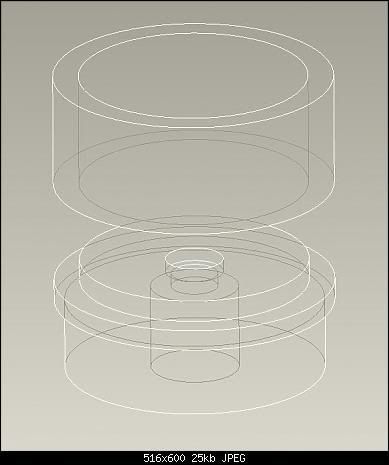

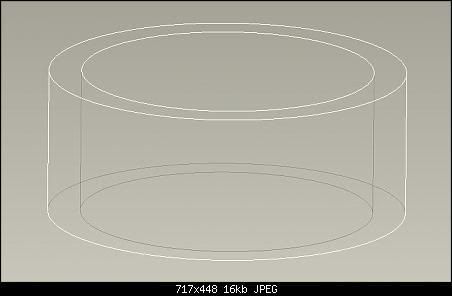

After going through a few tests and revisions, we have two final designs for a heatsink which will fit the common MXDL host, and the renowned Dorcy host. The diode will sit snugly around a large mass of aluminium. At the front there is a thread directly cut into the heatsink, perfect for both acrylic and glass Aixiz lenses. At least for the Dorcy, it will be flush with the head, with rounded corners to match the Dorcy's style of "no sharp edges". There should be sufficient space in the rear for most driver circuits.

At present I have the final revision on paper, ready to make in the next few days, but I've attached several images of previous prototypes to give you a close idea.

The latest design has changed considerably, and CAD images have been attached lower down.

The latest design revision incorporates a few changes based upon the feedback I've received from various members.

Briefly outlined:

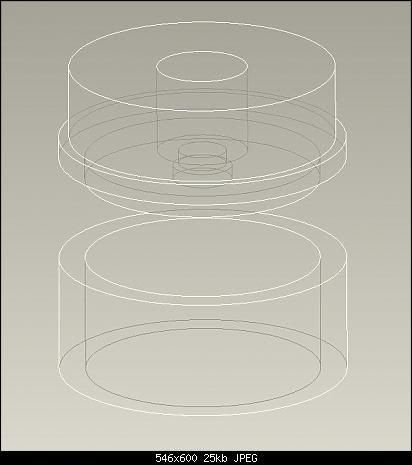

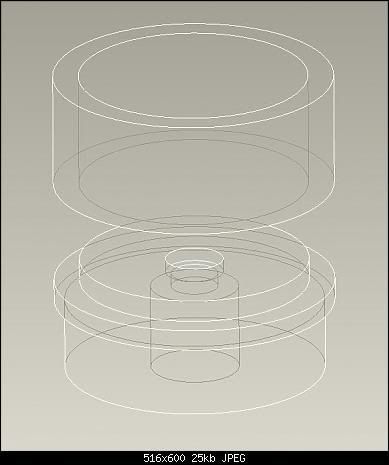

Diode Access - The bore on the rear of the heatsink has been removed, so the diode is now located at base of the heatsink, with the pins protruding (like in the head of an Aixiz module). There is a stepped recess for a same sized piece of tube (made from exactly the same material) which will press in, to give the total height of the heatsink as before. The coupling will not be a tight press fit, it will be snug, but not loose. Typical hand forces should be more than enough to add and remove the tube as you please. This means you will have much more access when soldering your diode; either directly to the PCB or with wires.

Diode Installation - There is a slight taper on the ledge the diode sits on, this aids installation of the diode

Cosmetic changes - Mainly to the front end, it's a lot more compact, i.e. so that it no longer protrudes from the host, it will be flush with the Dorcy's head, with a small radius around the end diameter

Circuitry Space - There should be sufficient space inside the tube for most circuits, however I'd just like to point out that the heatsink as a whole does not go past the small black plastic ring inside the Dorcy, therefore there is a bucket load more space there to put larger circuits or more components. The space available for circuitry at the rear will be: 9mm deep by 22mm diameter.

Please send your thoughts and suggestions this way on how to improve or modify the design, or suggest other common hosts the same design could be applied to.

I plan on making all these myself and if all goes well, and people would like to buy some, then I'm sure I could whip a batch for sale in the shop (if HighOctane agrees ). However, at least initially, there will be a strictly limited supply, as my lathe resides at home, and I'm off at university for several weeks on end between stopping at home for the weekend.

Also, rather than calling them just 'heatsinks'. This lump of metal needs a good name! My initial thoughts are the "X-sink" or "Laser Chill". However I smell a competition coming on shortly...

But for now all I'd like is your general thoughts and interest on them. Would anyone buy one here?

Can I just stress that this is NOT a GB, and I'm NOT asking for any money, just an 'interest gauge' so to speak.

Enjoy!

Dan

************************Modified January 2, 2009*********************************

Ok, a quick update: I'm going to get these made professionally at a machine shop as I don't have the time to make a suitably sized batch while at university. I'm going to get 40 MXDL style made and 10 Dorcy's made

As the first batch is in limited quantities - get your name down now, as they will be sent on a first-come, first-served basis.

Pm Daniel or Catmandoo and we will list the names in this thread, Paypal is the prefered payment method.

Both the Dorcy and the MXDL will sell for $25 each, with larger bulk discounts available upon request. As this is the first batch, I'll throw in a free tube of thermal compound with each one sold! How's that for added value?

I'm going to roadtest another one shortly, as soon as my next lot of diodes arrive, with a long open can red burner in, and really turn up the current, to make one smokin' laser. I'll whack an Aixiz glass lens in, and see how the duty cycle goes at high currents. I'm hoping for 300mW+ at 100% duty cycle *fingers crossed*

MXDL host that these are designed for http://www.dealextreme.com/details.dx/sku.4171

Here is the Dorcy tactical

http://www.amazon.com/Dorcy-41-4290...ref=sr_1_1?ie=UTF8&s=hi&qid=1230945426&sr=8-1

The scheduled release date is early to mid february so start ordering early if you want in on the first batch !

Daniel

Here is the list of orders.

Lasersbee, 2, MXDL

Hi All,

Over Christmas Greg (CMD) and myself have been exchanging ideas for a heatsink in which the diode mounts directly into, thus providing the best possible cooling in a stylish package, tailored to fit specific hosts. We've both had this idea for a while, but it's only really come into fruition in the last week or so.

*Latest Version: V0.4*

*This initial post has been updated to reflect latest design*

The heatsinks will be hand made from solid aircraft-grade aluminium bar (6082 T6), and a light brushed finished applied.

After going through a few tests and revisions, we have two final designs for a heatsink which will fit the common MXDL host, and the renowned Dorcy host. The diode will sit snugly around a large mass of aluminium. At the front there is a thread directly cut into the heatsink, perfect for both acrylic and glass Aixiz lenses. At least for the Dorcy, it will be flush with the head, with rounded corners to match the Dorcy's style of "no sharp edges". There should be sufficient space in the rear for most driver circuits.

At present I have the final revision on paper, ready to make in the next few days, but I've attached several images of previous prototypes to give you a close idea.

The latest design has changed considerably, and CAD images have been attached lower down.

The latest design revision incorporates a few changes based upon the feedback I've received from various members.

Briefly outlined:

Diode Access - The bore on the rear of the heatsink has been removed, so the diode is now located at base of the heatsink, with the pins protruding (like in the head of an Aixiz module). There is a stepped recess for a same sized piece of tube (made from exactly the same material) which will press in, to give the total height of the heatsink as before. The coupling will not be a tight press fit, it will be snug, but not loose. Typical hand forces should be more than enough to add and remove the tube as you please. This means you will have much more access when soldering your diode; either directly to the PCB or with wires.

Diode Installation - There is a slight taper on the ledge the diode sits on, this aids installation of the diode

Cosmetic changes - Mainly to the front end, it's a lot more compact, i.e. so that it no longer protrudes from the host, it will be flush with the Dorcy's head, with a small radius around the end diameter

Circuitry Space - There should be sufficient space inside the tube for most circuits, however I'd just like to point out that the heatsink as a whole does not go past the small black plastic ring inside the Dorcy, therefore there is a bucket load more space there to put larger circuits or more components. The space available for circuitry at the rear will be: 9mm deep by 22mm diameter.

Please send your thoughts and suggestions this way on how to improve or modify the design, or suggest other common hosts the same design could be applied to.

I plan on making all these myself and if all goes well, and people would like to buy some, then I'm sure I could whip a batch for sale in the shop (if HighOctane agrees ). However, at least initially, there will be a strictly limited supply, as my lathe resides at home, and I'm off at university for several weeks on end between stopping at home for the weekend.

Also, rather than calling them just 'heatsinks'. This lump of metal needs a good name! My initial thoughts are the "X-sink" or "Laser Chill". However I smell a competition coming on shortly...

But for now all I'd like is your general thoughts and interest on them. Would anyone buy one here?

Can I just stress that this is NOT a GB, and I'm NOT asking for any money, just an 'interest gauge' so to speak.

Enjoy!

Dan