Hello Everyone, First post so take it easy  .

.

Driver Design Intent:

I have long wondered why we don't see drivers that can change output like most modern flashlights. I really like the idea of being able to use my 100+mw laser pointer for less blinding tasks. I have since embarked on crashing the 2 worlds of LPF and BLF together.

Design:

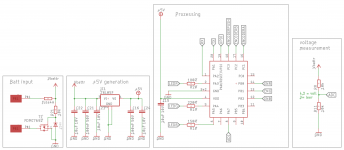

I have started a design based on the Benboost Mini using a LM3140, then added a Attiny13a microcontroller to deal with the PWM control on the Dim pin of the LM3410. Thanks to some very intelligent and generous members of the Flashlight Community. I managed to find, then tweak some .c code to change a PWM signal every time the power cycled with a tail switch.

Everything worked great when I was proving this design on a breadboard, so I went ahead and get to work on a PCB. I figured why not use a Flashlight host to house this, as they are readily available in a multitude battery configurations. So got a few 18mm boards made and get everything soldered up.

Issues:

I am not well versed in EE or PCB Design and have basically stubbled though this which brings me to asking for help. I cannot seam to get consistent function out of the microcontroller when it is attached to the PCB. I have a few theories based on complete guesses. Maybe drawing power direct from the same leg as the inductor might be sending unwanted voltage spikes to the MCU?

Summary:

I have added the schematic and PCB design as it stands with a project name of "VLD" (or Variable Laser Driver). In its current state v1 is semi functional. As in powers a test load and laser diode but the mode cycling is just random. I hope that some members with more experience in driver design and an interest in adapting multimode operation like the Flashlight community might have some insight into possible upgrades to the current design. I have this in an EasyEDA project too and would love to share with the community in whatever way would be easiest.

If you made it this far thanks for reading.

Driver Design Intent:

I have long wondered why we don't see drivers that can change output like most modern flashlights. I really like the idea of being able to use my 100+mw laser pointer for less blinding tasks. I have since embarked on crashing the 2 worlds of LPF and BLF together.

Design:

I have started a design based on the Benboost Mini using a LM3140, then added a Attiny13a microcontroller to deal with the PWM control on the Dim pin of the LM3410. Thanks to some very intelligent and generous members of the Flashlight Community. I managed to find, then tweak some .c code to change a PWM signal every time the power cycled with a tail switch.

Everything worked great when I was proving this design on a breadboard, so I went ahead and get to work on a PCB. I figured why not use a Flashlight host to house this, as they are readily available in a multitude battery configurations. So got a few 18mm boards made and get everything soldered up.

Issues:

I am not well versed in EE or PCB Design and have basically stubbled though this which brings me to asking for help. I cannot seam to get consistent function out of the microcontroller when it is attached to the PCB. I have a few theories based on complete guesses. Maybe drawing power direct from the same leg as the inductor might be sending unwanted voltage spikes to the MCU?

Summary:

I have added the schematic and PCB design as it stands with a project name of "VLD" (or Variable Laser Driver). In its current state v1 is semi functional. As in powers a test load and laser diode but the mode cycling is just random. I hope that some members with more experience in driver design and an interest in adapting multimode operation like the Flashlight community might have some insight into possible upgrades to the current design. I have this in an EasyEDA project too and would love to share with the community in whatever way would be easiest.

If you made it this far thanks for reading.