- Joined

- Nov 4, 2014

- Messages

- 1,146

- Points

- 63

Hey LPF,

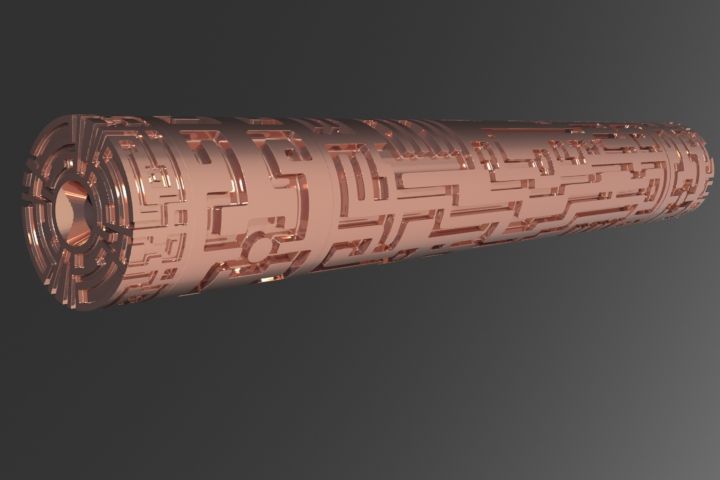

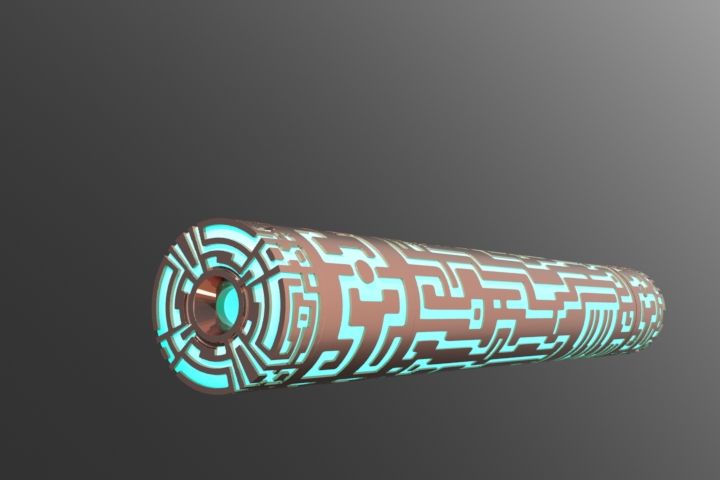

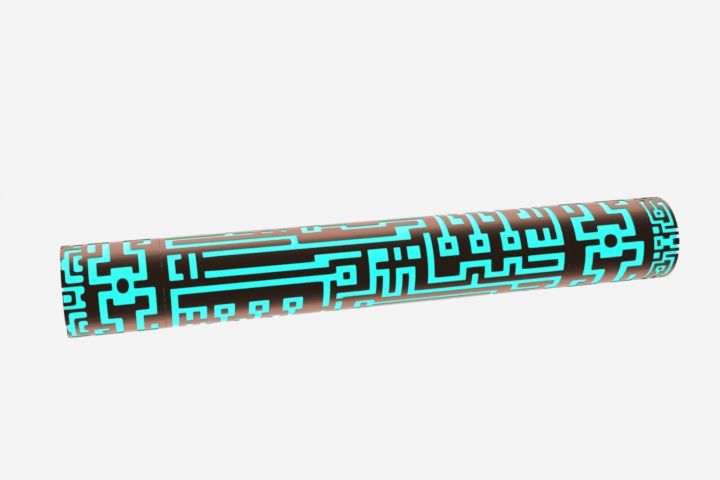

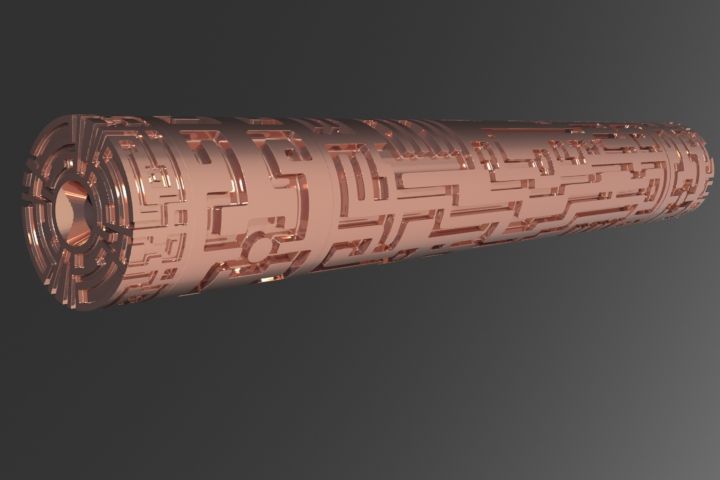

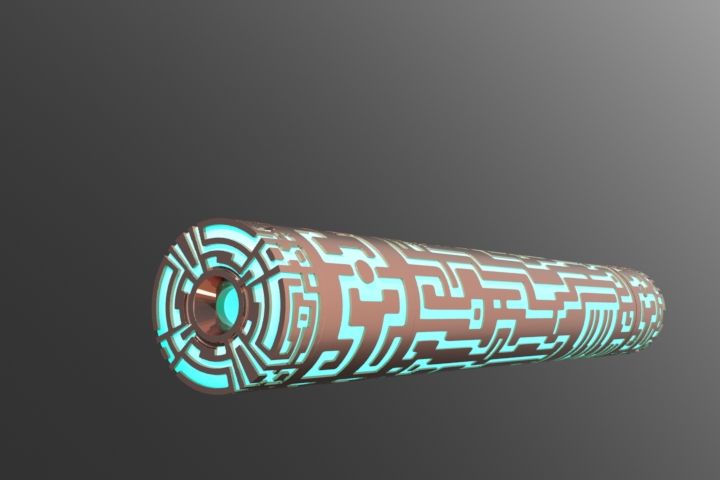

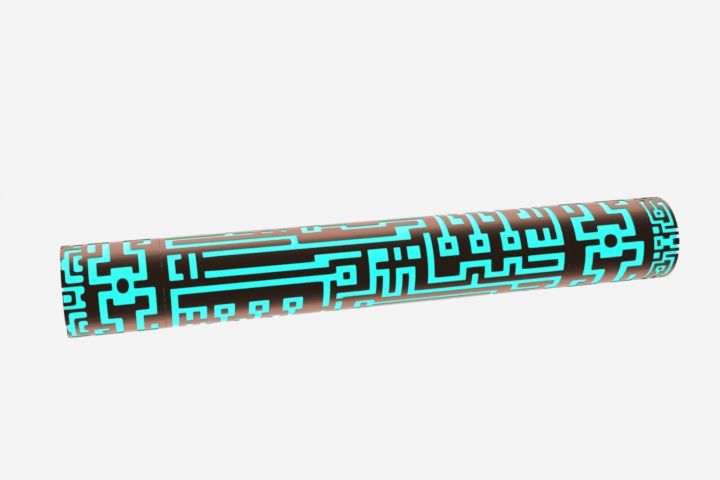

I'm excited to share the host project myself and my friend/housemate have been working on the past few weeks. We decided to build an all copper host from the ground up roughly the size of the Kryton Groove and see what becomes of it. The inspiration of the design was my time my wife and I spent living with the Shipibo-Conibo tribe in the lower Amazon of Peru from 2011-2012. The Shipibo are known for their psychedelic patterns in which they sew by hand on tapestry and clothing inspired by the visions seen during the ayahuasca ceremonies. I personally partook in over 20 ceremonies during my time in the amazon and it changed my artistic direction quite a bit. Much of my personal art has been heavily influenced by the Shipibo as well as many other indigenous cultures of the world and it was our hope to capture a piece of this inspiration in metal for this creation. The patterns seen and drawn by the Shipibo always have reminded me of a convergence of indigenous cultures meets futuristic alien technology.

We are going to start with the all copper, press-fit module version first and build it to completion to make sure its functional. Direct diode press fit versions may be something we explore as well and I would appreciate hearing your feedback regarding these two ideas. After we get one built and working we will have more made for various other versions such as playing with different copper patinas, powder coat or auto paint with and with out GITD inlays.

Below are some renderings to give a glimpse of what they will look like. The design was made on a 3D modeling program called MODA so it is ready to go for the machinist with a CNC lathe and mill. Luckily we have some enthusiasm and support of some incredibly talented people. There is even talk about building some of the host body out of Damascus steel which would be amazing. My friend working with me on this is a well known jewelry designer so he has some good friends and contacts in the metals industry and have some have taken an interested in our endeavor. So stay tuned for up-dates if you're interested.

We are excited about this project and the hundred hours plus of designing and modeling will all be worth it soon.

I'm excited to share the host project myself and my friend/housemate have been working on the past few weeks. We decided to build an all copper host from the ground up roughly the size of the Kryton Groove and see what becomes of it. The inspiration of the design was my time my wife and I spent living with the Shipibo-Conibo tribe in the lower Amazon of Peru from 2011-2012. The Shipibo are known for their psychedelic patterns in which they sew by hand on tapestry and clothing inspired by the visions seen during the ayahuasca ceremonies. I personally partook in over 20 ceremonies during my time in the amazon and it changed my artistic direction quite a bit. Much of my personal art has been heavily influenced by the Shipibo as well as many other indigenous cultures of the world and it was our hope to capture a piece of this inspiration in metal for this creation. The patterns seen and drawn by the Shipibo always have reminded me of a convergence of indigenous cultures meets futuristic alien technology.

We are going to start with the all copper, press-fit module version first and build it to completion to make sure its functional. Direct diode press fit versions may be something we explore as well and I would appreciate hearing your feedback regarding these two ideas. After we get one built and working we will have more made for various other versions such as playing with different copper patinas, powder coat or auto paint with and with out GITD inlays.

Below are some renderings to give a glimpse of what they will look like. The design was made on a 3D modeling program called MODA so it is ready to go for the machinist with a CNC lathe and mill. Luckily we have some enthusiasm and support of some incredibly talented people. There is even talk about building some of the host body out of Damascus steel which would be amazing. My friend working with me on this is a well known jewelry designer so he has some good friends and contacts in the metals industry and have some have taken an interested in our endeavor. So stay tuned for up-dates if you're interested.

We are excited about this project and the hundred hours plus of designing and modeling will all be worth it soon.

Last edited: