- Joined

- Jun 24, 2010

- Messages

- 5,705

- Points

- 113

I had been keeping my eye out for some time for one of the guys making Meters for the Ophir heads to add an input plugs for the power supply and output to the laser diode so it could add current and voltage to the data logging output.

In lieu of that I have been looking around at a lot of stuff to be able to make something myself that will automate nice power graphs without having to manually input all the observations into excel from my power tests. I would need datalogging for two voltages and a current reading or I guess I could go with three voltages and use a measurement across a 1ohm resistor in mV for the current to the diode.

Been looking for a cheap datalogger that would work for this and looking for some suggestions. Mabye something like this would work for the three voltage logging method.

DI-145 USB Data Acquisition Starter Kit

Basically I want to capture in say 0.1 or 0.25 second increments the voltage from the power supply to the laser, the current from the power supply to the laser and the voltage from the output of the LPM to the LCD voltage meter display to give me three nice columns of V/mA/mW.

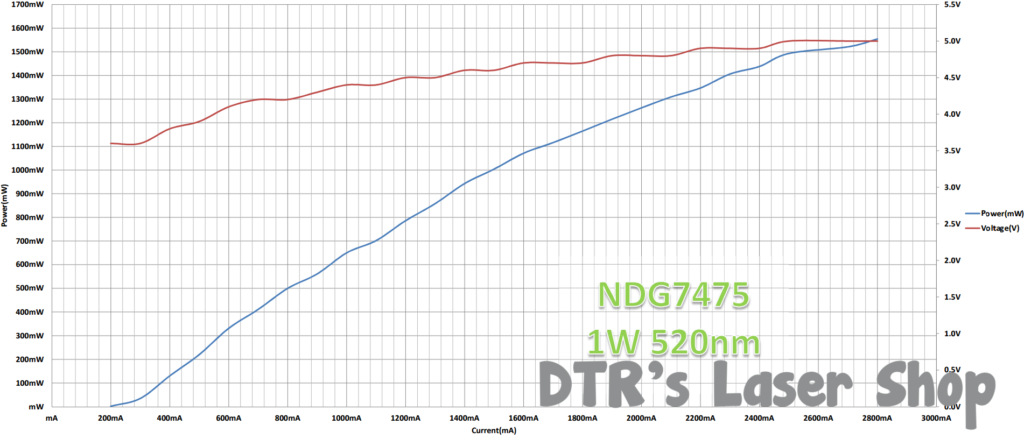

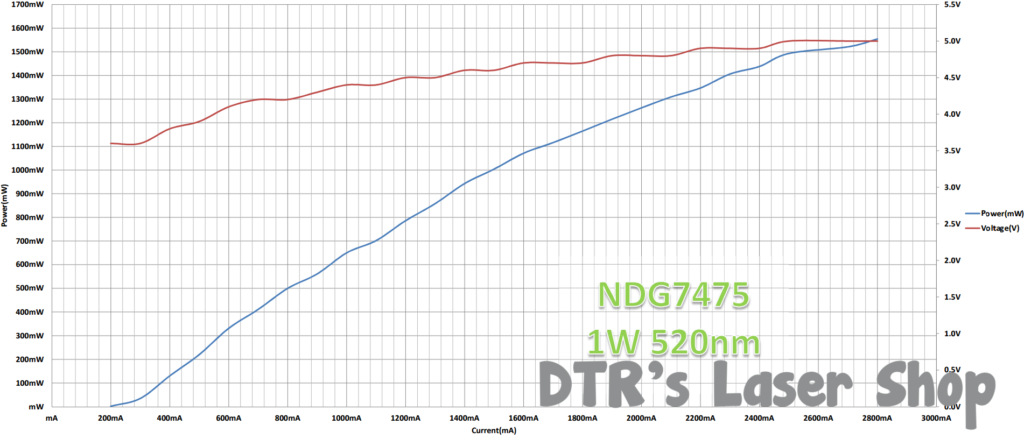

Anyway I can make ones like these the old fashioned way but would like for more resolution to give a better curve and less manual input and picturing. The waviness on this is due to the supply having a resolution of 100mA and not knowing if I am at 1-99mA in that range. I there is a fine adjustment on the supply which I can get my reading right when it flips to the next 100mA range but it is not seeming to be as accurate as I would like and it takes time while powered which makes heat more of a factor. Anyway seeing if there are any suggestions on a good setup.

In lieu of that I have been looking around at a lot of stuff to be able to make something myself that will automate nice power graphs without having to manually input all the observations into excel from my power tests. I would need datalogging for two voltages and a current reading or I guess I could go with three voltages and use a measurement across a 1ohm resistor in mV for the current to the diode.

Been looking for a cheap datalogger that would work for this and looking for some suggestions. Mabye something like this would work for the three voltage logging method.

DI-145 USB Data Acquisition Starter Kit

Basically I want to capture in say 0.1 or 0.25 second increments the voltage from the power supply to the laser, the current from the power supply to the laser and the voltage from the output of the LPM to the LCD voltage meter display to give me three nice columns of V/mA/mW.

Anyway I can make ones like these the old fashioned way but would like for more resolution to give a better curve and less manual input and picturing. The waviness on this is due to the supply having a resolution of 100mA and not knowing if I am at 1-99mA in that range. I there is a fine adjustment on the supply which I can get my reading right when it flips to the next 100mA range but it is not seeming to be as accurate as I would like and it takes time while powered which makes heat more of a factor. Anyway seeing if there are any suggestions on a good setup.