upaa27

0

- Joined

- Jul 10, 2013

- Messages

- 618

- Points

- 28

Hello all,

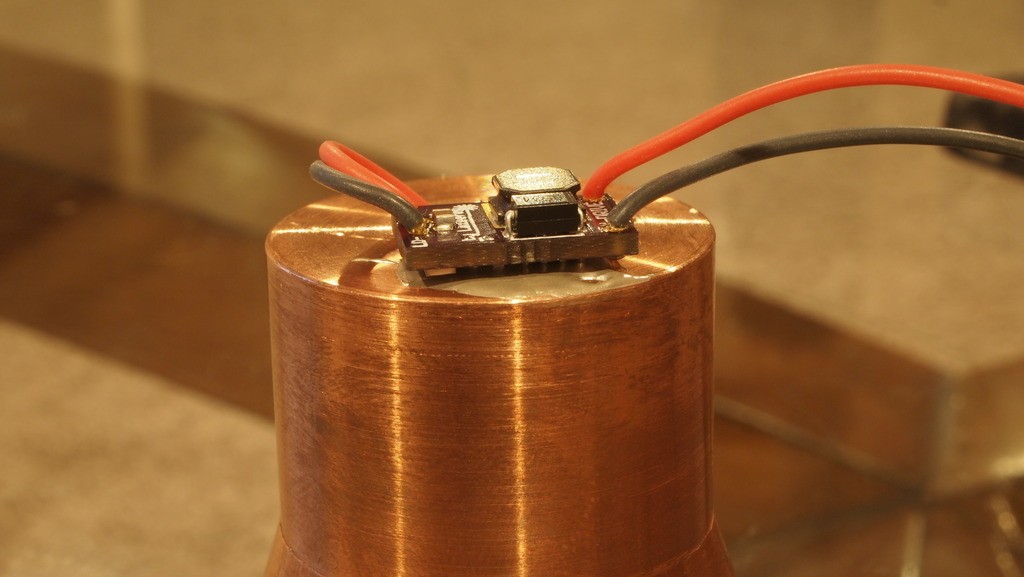

As you all know the x-drive is a rectangular shape and I have mine set at 3.5 amps. Running it this high really needs heat sinking although I do not know the best way to do this. I read that you can just epoxy on a slab of copper but that seems very crude unless you fin it. What would you guys do?

Right now I am leaning toward epoxying the driver to the host but his might make it difficult to remove.

As you all know the x-drive is a rectangular shape and I have mine set at 3.5 amps. Running it this high really needs heat sinking although I do not know the best way to do this. I read that you can just epoxy on a slab of copper but that seems very crude unless you fin it. What would you guys do?

Right now I am leaning toward epoxying the driver to the host but his might make it difficult to remove.