- Joined

- Apr 8, 2009

- Messages

- 56

- Points

- 0

I set out to design and prototype a good single cell 445nm boost driver a while ago, because I have a need for it.

I have tried many designs and I'm having success with some of them.

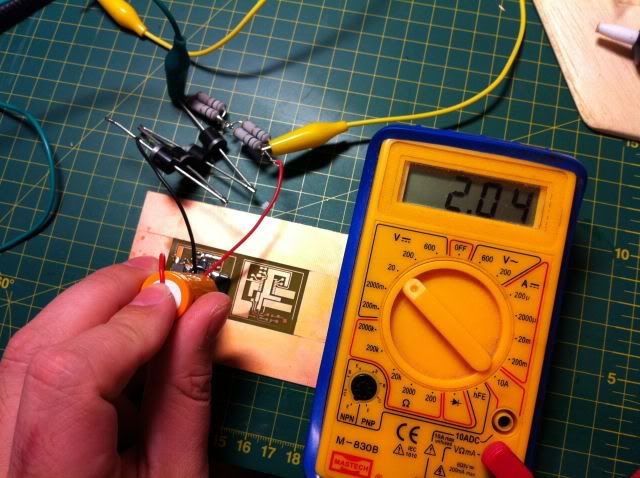

At the moment up to 2.4A @ 5.5V isn't a problem with an 18650. Even a good 18350 works. Running at 1.8A @ 4.8V I can achieve 82% efficiency.

All my boost circuits are continuous ground with high-side current sensing and current regulation.

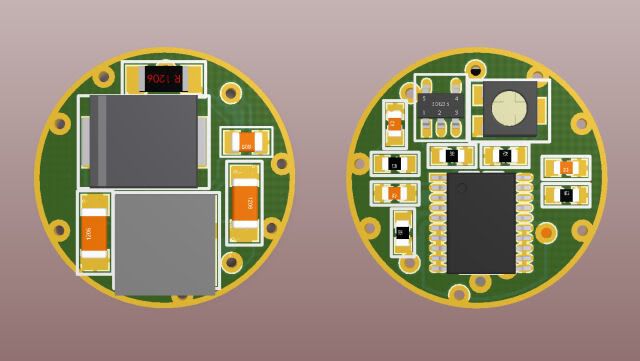

My main mission now is to buy the best components in the smallest size and shrink one of the drivers as small as possible. 16mm Round might be possible, but only when stacking PCBs.

Are there hosts that use a larger round driver?

I have contacts at an assembly house, and depending on pick&place costs I might do a production run in the future.

What other drivers do you guys think there might be a need for? I like designing and prototyping in my free time.

I have tried many designs and I'm having success with some of them.

At the moment up to 2.4A @ 5.5V isn't a problem with an 18650. Even a good 18350 works. Running at 1.8A @ 4.8V I can achieve 82% efficiency.

All my boost circuits are continuous ground with high-side current sensing and current regulation.

My main mission now is to buy the best components in the smallest size and shrink one of the drivers as small as possible. 16mm Round might be possible, but only when stacking PCBs.

Are there hosts that use a larger round driver?

I have contacts at an assembly house, and depending on pick&place costs I might do a production run in the future.

What other drivers do you guys think there might be a need for? I like designing and prototyping in my free time.