- Joined

- Dec 21, 2008

- Messages

- 1,223

- Points

- 0

Intro

One of my other hobbies is sports & tactical cutlery. This short pictorial-essay what-have-you is geared towards the cutlery crowd, with the assumption that their knowledge of LED-tech is on average, on par with mine. I doubt that will be the case here at LPF, where most have been enjoying this both Laser diode and LED science infinitely longer. So please take this into consideration when sifting through the text. Feel absolutely free to correct me if/where necessary - I'm always eager to learn more! Worst case, the photos are pretty good...

:beer:

Fanatic about Photons

Fred, aka Photonfanatic over in CPF has been “playing with” things that go bright in the night for quite some time now and a few years back, started to admire the work custom knifemakers were doing and the materials they were investigating to push the art forward. Fred is no stranger to base metals & alloys, having made numerous [flashlight] hosts from stainless, aluminum and Titanium too. He anodized the Titanium, splashed the aluminum, bead-blasted / polished and coated just about everything (using just about everything - PVD, DLC, …).

(above photos c/o Photonfanatic)

Fred, being well, “Fred”, wasn’t satisfied making functional art out of just these materials and decided to try his hand at various forms of damascus. There was Mokume Gane (bi / tri-color, using nickel / copper), then came a wave of Chad Nichols' awesome stainless Damascus (nickel & SS). Once he was done with "plain" damascus, he gave mosaic damascus a try and created something so special that it’s making it’s way around the Country to get photographed

(above photos c/o Photonfanatic)

Next step in the evolution

After having admired his work for some time now, particularly with his enthusiasm to try out new materials, I asked him about his thoughts on the various Welded Titanium alloys in use by the knife-making community. Little did I know that thanks to co-damascus-fanatic Scott (aka ScottN in the cutlery community), Fred already had organized to get a bar of Chad's MokuTi! Well that certainly got me excited, not to mention Fred had already planned to make a WIP out of it For those of you who are less familiar with the material, Chad is taking a similar pattern-welded technique used for Damascus and applying it to Titanium. For Mokuti, Chad uses industry-standard 6AL4V Ti and layers it with "commercially pure" (CP) Ti. Many knifemakers have used this pattern-welded Ti to make some seriously amazing handles, scales, clips, thumb studs and even pivot-screws (!) for their knives and folders. The only other similar product available is AKS' Timascus - available in white and black (which uses zirconium in the mix).

For those of you who are less familiar with the material, Chad is taking a similar pattern-welded technique used for Damascus and applying it to Titanium. For Mokuti, Chad uses industry-standard 6AL4V Ti and layers it with "commercially pure" (CP) Ti. Many knifemakers have used this pattern-welded Ti to make some seriously amazing handles, scales, clips, thumb studs and even pivot-screws (!) for their knives and folders. The only other similar product available is AKS' Timascus - available in white and black (which uses zirconium in the mix).

Click-the-pics for hi-res goodness.

Mad Skillz

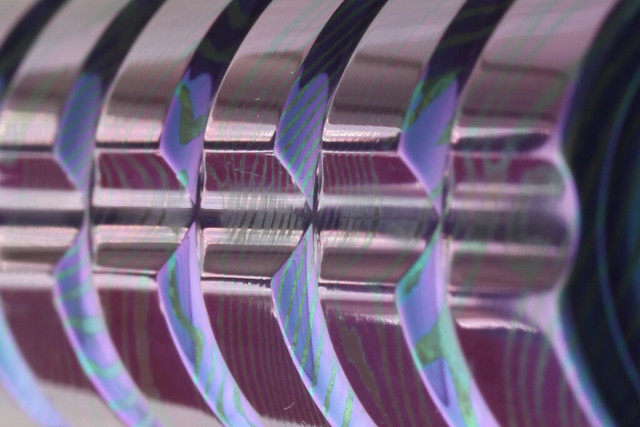

If it hasn't dawned on you yet, Fred has a good eye for design and the skills to bring that design from his mind into reality. Amazingly, Fred uses very few machines compared to the average modern knifemaker and (naturally), the machines are geared toward cylindrical objects (you won't find a flat grinder in Fred's shop - heck not even sure he has a "grinder"... hand-polishing, definitely ) Some materials are child's play for him, others give him a bit of a hard time, but no matter what the material, you can bet it will be perfect...

) Some materials are child's play for him, others give him a bit of a hard time, but no matter what the material, you can bet it will be perfect...

New horizons

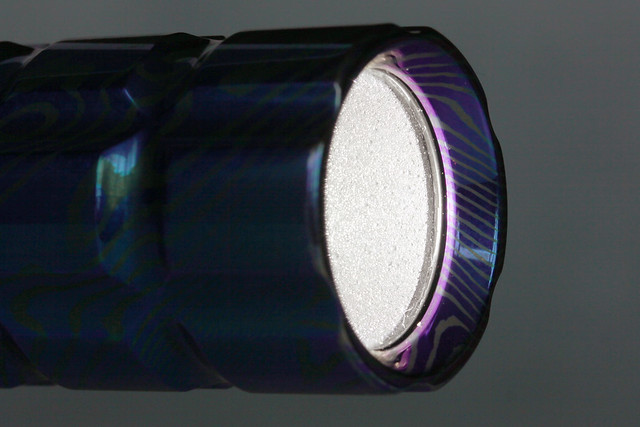

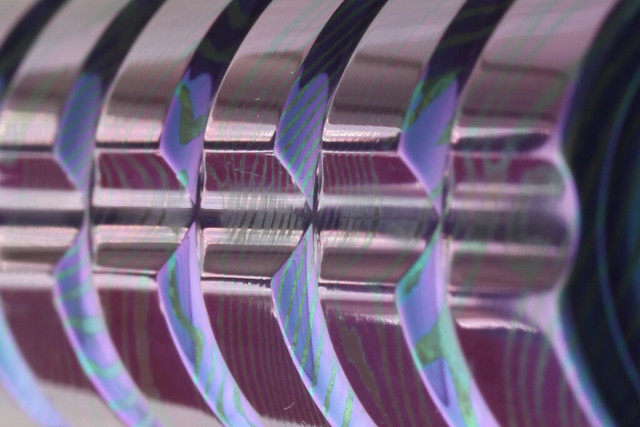

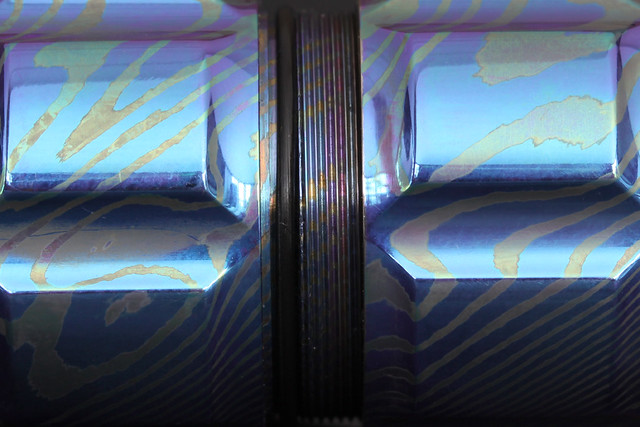

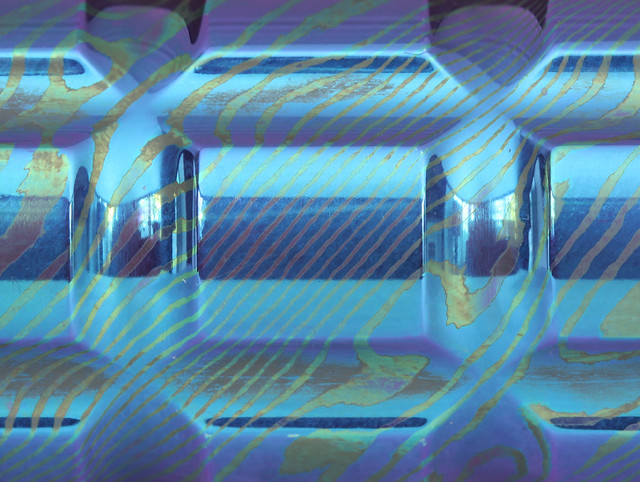

With every new material comes new adventures; some involve minor effort (material density, hardness etc.) others present interesting challenges. Making Mokuti colorful is one of the latter, as Fred soon found out! Just sifting through his WIP reveals how many color variations you can achieve by changing a few variables, like solution, voltage and yes, even surface finish (matt, polished, ultra-polished...). As I was following his WIP with great interest, I occasionally suggested some color-combos that I thought would be cool; I mentioned Warren Thomas' amazing Alien skin and the color tones he gets out of his [6AL4V] Ti work; I hinted at what Allen Elishewitz had done for me, coming up with some gorgeous MokuTi bolsters (pictured in the last section) and so on.

After a few weeks of experimentation, Fred did manage to sort out what variables would produce certain color ranges but just as importantly, he learned what many a knifemaker already knew, Mokuti is a beautiful, exotic and unpredictable creature. One can aim for a color-range, but that's as close as you will get with Mokuti; Titanium is not as predictable as the Nickel and steel found in classic damascus...

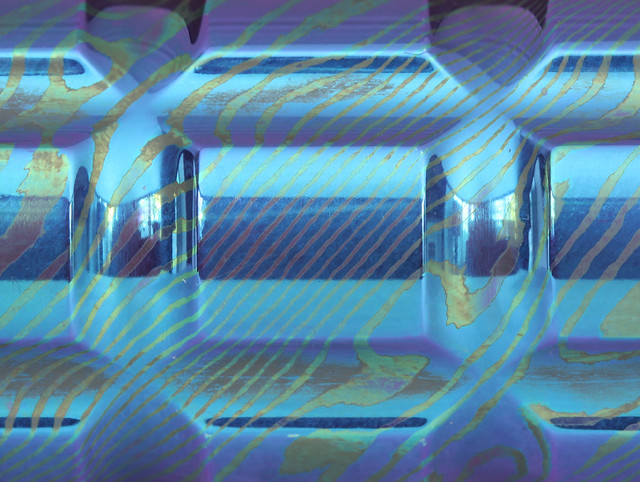

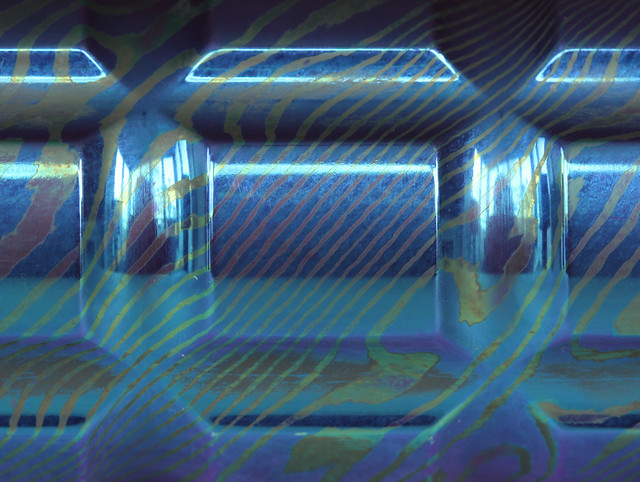

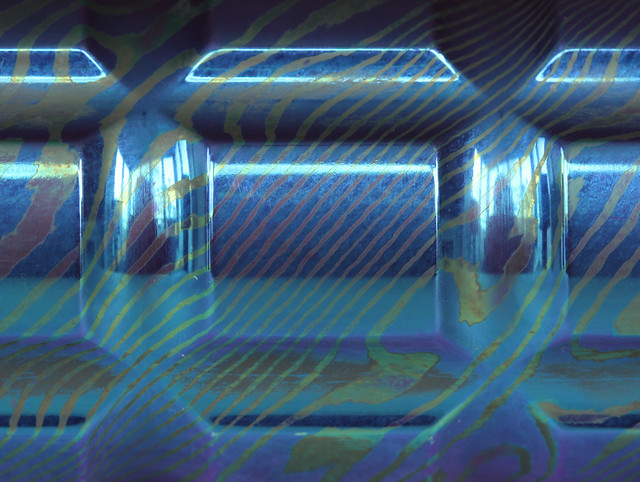

Base colors are blue and gold, "interference" colors are purple and green...

Mad eSkillz

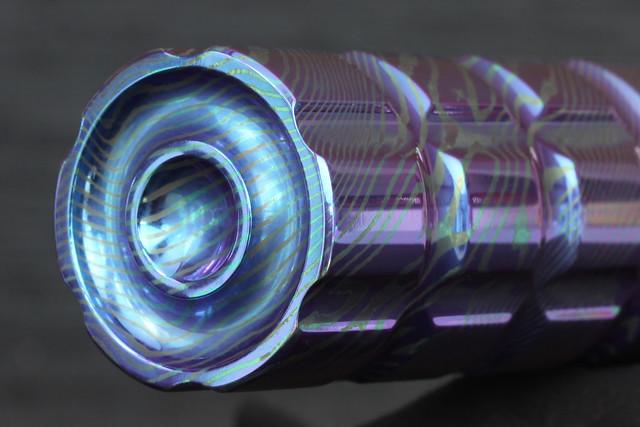

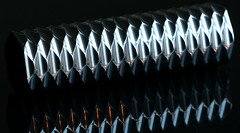

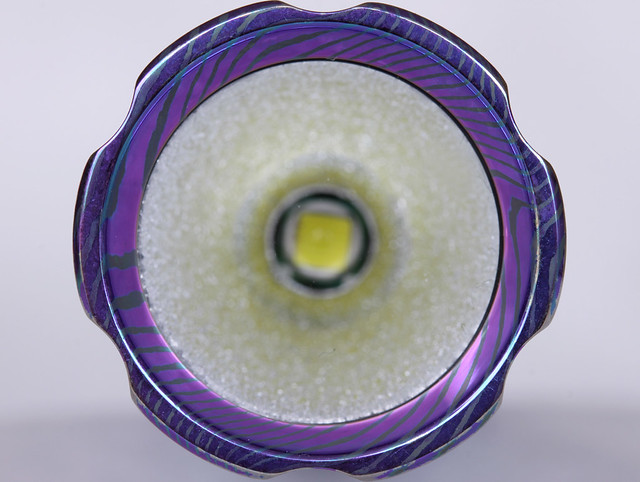

Fred's hosts are some of the most creative and artistic in the customs-flashlight arena, but he doesn't make hosts, he makes handheld flashlights. Not just any flashlights, but state of the custom-world art ones. The Block Party may be stunning to look at, but it is a formidable powerhouse of a light too. First off, some specs:

Host: Chad Nichols MokuTi - welded Titanium (Ti alloy & Commercially Pure Ti), Solution anodized

Length: 120mm (4.7"), diameter: 25mm (1.0")

Weight: 170g (6.0oz) - including 47g 18650

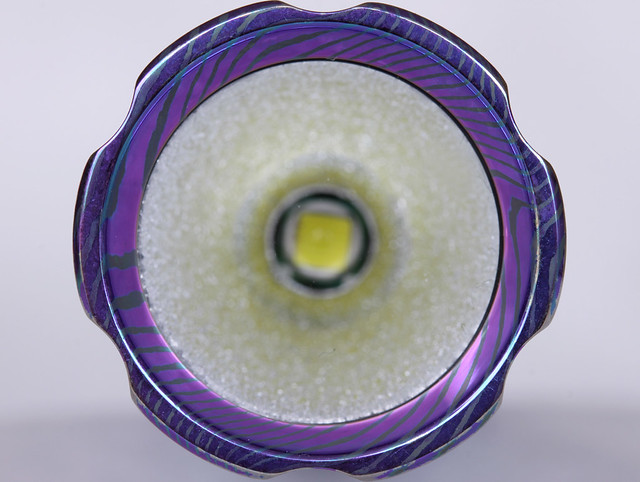

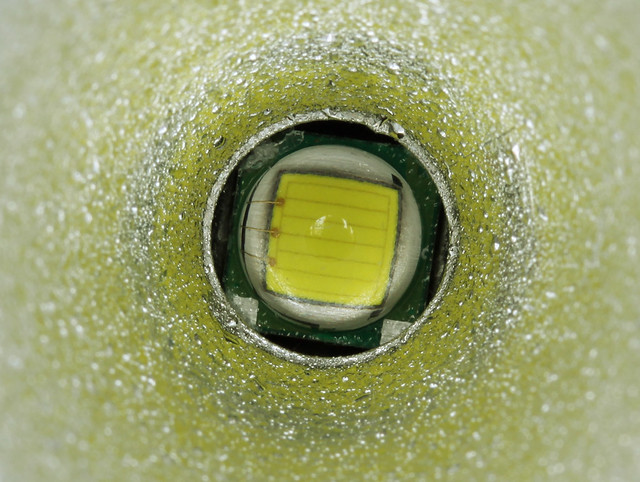

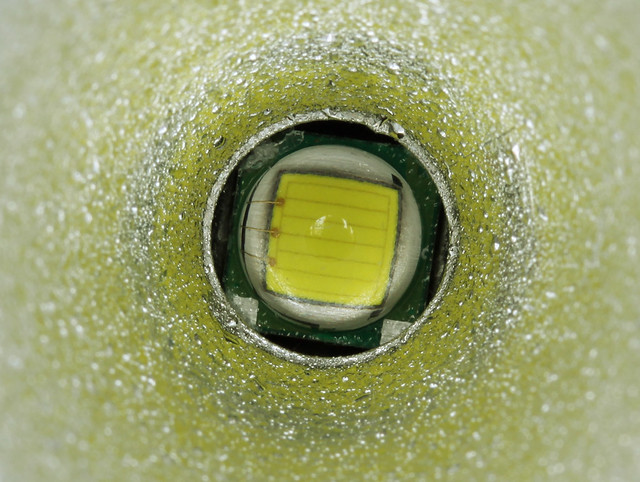

Emitter: Cree XM-L (U2 bin) mounted on a 2mm thick MCPCB (Copper base)

Driver: Three-mode regulated (140mA, 1A, 2.8A), memory mode

Power Source: 18650 Rechargeable 3.7V battery (1)

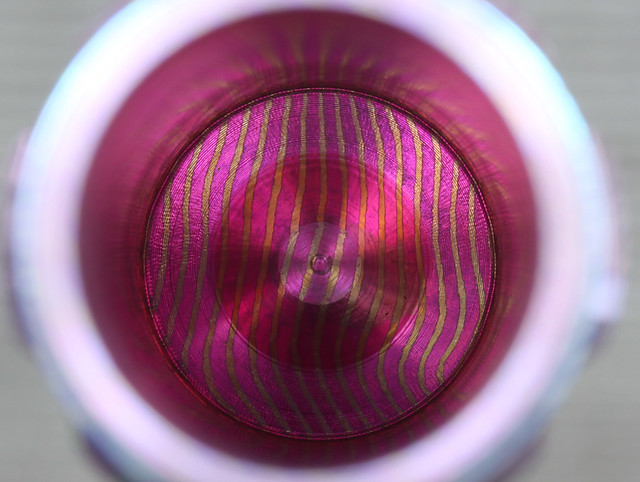

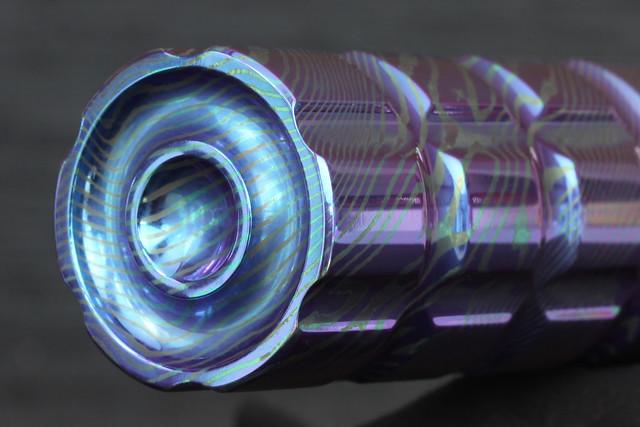

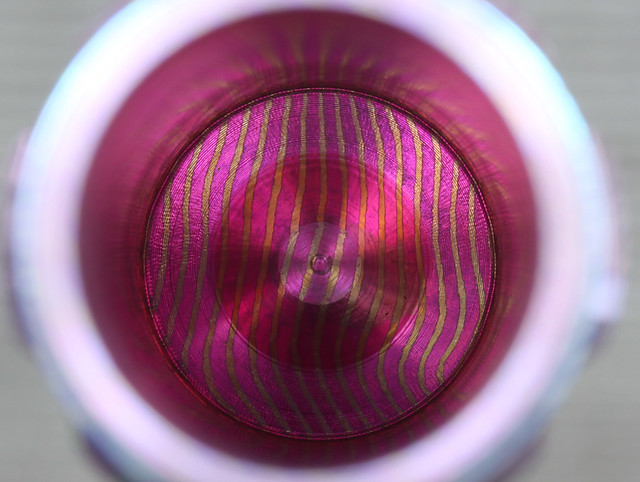

Reflector: 20mm Khatod, stippled (orange peel)

Output: < 500 lumens (before glass)

Operation: "Twisty"

Other: O-ring seals for water resistance, 2mm-thick mineral glass, silicone gasket (instead of commonplace spring)

While I am no expert in the area of LED flashlights, I'm familiar with the basic principles and will review them for those with a heavier background in knives. Every light has a specific design in mind; illumination of a broad area, of a target area, or a bit of both. This is controlled by several design aspects of a light; the LED type (Emitter), reflector shape, length and surface and the glass ("window"). These properties also affect total / perceived output, along with the driver (which supplies constant current to the emitter) and power source (battery).

Fred has jumped on the XM-L bandwagon, an emitter that has taken the custom community by storm, thanks mainly to both its efficiency and output capability. Coupled to a relatively hi-current driver, capable of delivering up to 2.8A to the emitter and powered by a 3.7V Li-Ion, Fred's "Light Engine" (LE) can put out an estimated 500 Lumens. In comparison, the typical tactical handheld is rated around 200~250 lumens and classic "incans" (incandescent lights) are rated usually around 60 lumens. Thus, a 500-lumen handheld will certainly light up the neighbor's house... While having that many lumens at your disposal is great, using it is another story. The first problem is that in most circumstances, the light will be too bright... way too bright. Secondly, an Emitter drawing 2.8A will drain even the most beefy of batteries (18650s are typically in the 2000~2600mAh range). I don't know the math, but I would venture to say that you can measure the longevity in minutes... . Enter the multi-mode driver! Fred selected a 3-mode driver (high@2.8A, medium@1A and low@140mA) for this build. Given these figures, we can assume medium will run a few hours and low will run a few days.

While having that many lumens at your disposal is great, using it is another story. The first problem is that in most circumstances, the light will be too bright... way too bright. Secondly, an Emitter drawing 2.8A will drain even the most beefy of batteries (18650s are typically in the 2000~2600mAh range). I don't know the math, but I would venture to say that you can measure the longevity in minutes... . Enter the multi-mode driver! Fred selected a 3-mode driver (high@2.8A, medium@1A and low@140mA) for this build. Given these figures, we can assume medium will run a few hours and low will run a few days.

Which brings us to the User Interface (UI). Most modern handheld lights use a side-button or a tail "clicky" or in the simplest form, are controlled by twisting the head ("twisty"). While Fred has done all of those, his philosophy is less is better. In other words, less moving parts provide for a more reliable solution. Simply twist the head clock-wise to turn it on, off/on within 1s "toggles" through the three modes. Once left on in any given mode for more than 2s, the driver will "remember" the mode the next time your turn on the light. Keeping in line with this minimalist principle, there are no springs in use; instead, a silicon gasket assures that battery remains secured. Fred's tolerances don't allow for much play anyways...

The illumination pattern of a flashlight generally consists of the hotspot, halo and Spill. Fred chose to make this one a "Wall of light" by using a stippled reflector of a shallow(er) depth. This in turn produces less of a prominent spot and enhances the spill. Thus you have a light that has good flood characteristics (wide angle of illumination), but less throw or reach (illumination distance). I happen to find this setup both unique and useful, not to mention aesthetic. Thanks to both Fred's build accuracy and chosen setup, the so-called halo is almost unnoticeable. If you've ever used an El Cheapo $15 LED handheld, then you know how drastic the contrast can be between the hotspot and spill, causing a high-contrast ring (and sometimes, even multiple rings... :rant:

Perfectionist

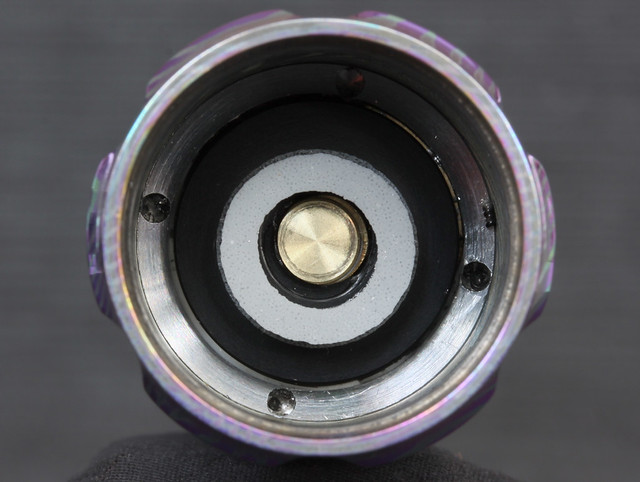

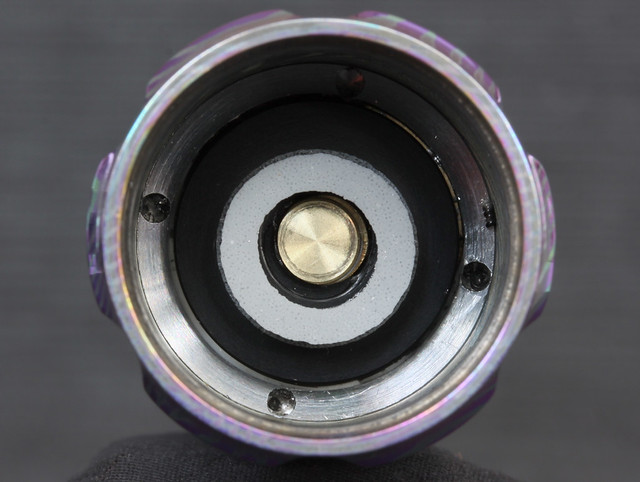

So far so good. Or maybe not. Fred apparently was not impressed with the fit & finish of the driver, noting that there were visible electronic components on the battery-side as the designers wanted to shave off an additional pcb layer ...sigh. So Fred, being, well "Fred", took it upon himself to correct this by machining a piece of delrin to cover the exposed electronics. Furthermore, he decided the factory-installed spring was crap, so he replaced it with a brass button. So when I say this is a custom light, I do damn well mean custom in every possible way... :bowdown:

before & after

before & after

(above photos c/o Photonfanatic)

Every rose has it's thorn

Or something like that (it's been a while since I was in English Lit. ...) The multi-mode driver used in this build uses a technology known as Pulse-Width Modulation (PWM). Unfortunately PWM has a few side effects when using the light in any mode other than high. The first is the fact that the light flickers at some (high) frequency. The second problem is that a PWM system can cause an audible "whine" (as recorded in this video). I cannot notice any flicker however I do hear the whine. The sound is barely noticeable in low but readily apparent in medium, assuming a quiet environment (like your basement, etc.) Fred, being well, "Fred", is looking at alternative drivers and trying to determine their operating frequencies, etc.

The only other possible area of concern is the heat output of an LED like the XM-L driven at 2.8A. When the light is on high, it will warm up in no time. After approx. 1min, the head will heat up to an uncomfortable level. This is normal for hi-powered handhelds and you will often see a warning sticker on the heads. Having foreseen the need to cool this emitter, Fred made the host longer then his usual 18650 hosts (120mm vs. 100mm) and housed the emitter and driver in a beefy Al heatsink. While it is hard to imagine a more attractive host, MokuTi or simply, titanium, is not the best material for head-dissipation. In general, Ag, Cu & Al are considered the best thermal conductors, with Al being the most popular due to its price/efficiency ratio.

Time will tell if operating such a high-powered Light Engine in such a sleek host will be feasible. In terms of real-world usage, Medium (@1A output and moderate heat emission) is the more useful mode, with high being only necessary in very rare circumstances (like showing the light off... :eg: ). The Block Party is primarily functional art and not intended for extreme operating environments (no tour-of-duty planned for this puppy )

)

Conclusion

Functional art is what Fred is all about; from the design principles, to the precision engineering and the desire to produce the very best that he can. This is what got my attention in the first place and this has only been reaffirmed now that I've had the pleasure to use and enjoy Fred's latest masterpiece, the Mokuti Block Party!

:beer: :beer: :beer: :beer: :beer:

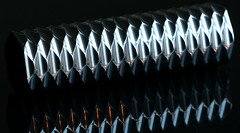

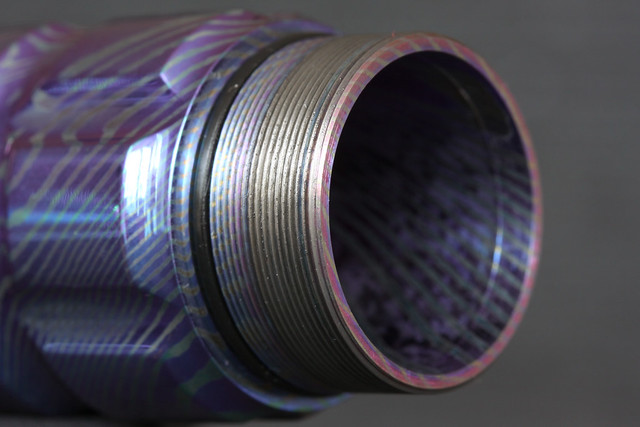

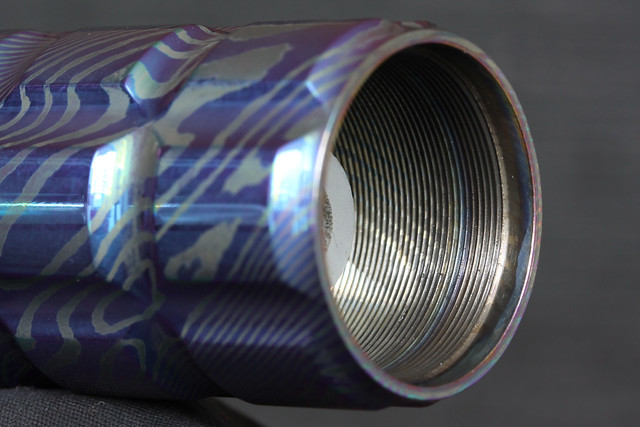

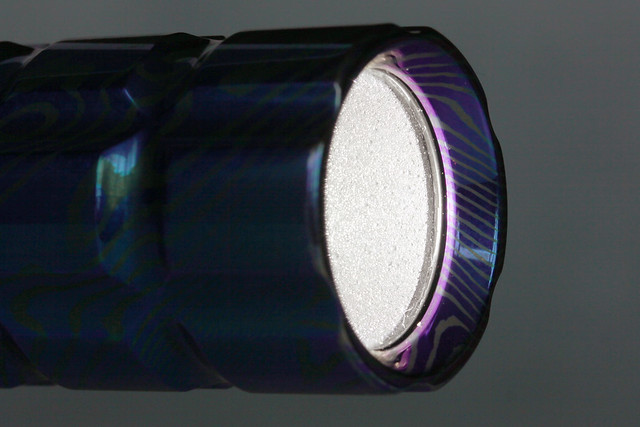

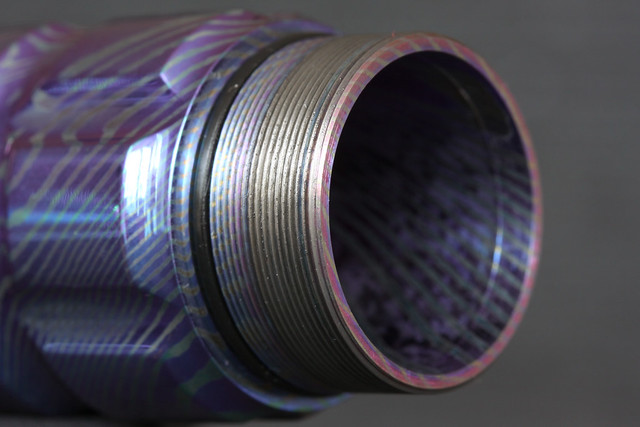

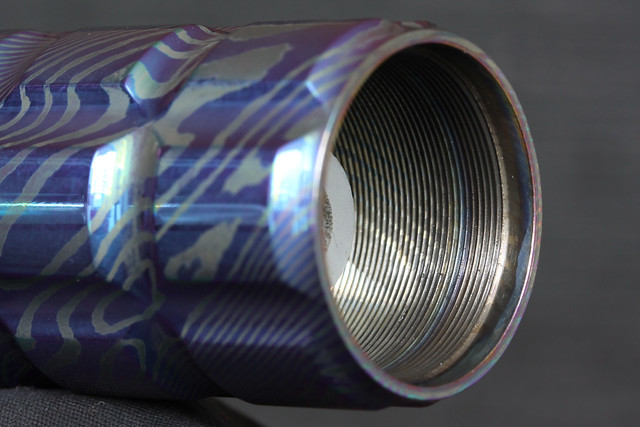

Precision-engineering, inside and out...

A MokuTi...

...Chameleon...

...in shades of blues, gold, purples and greens

Typical forms of illumination patterns*, from throw to flood, hotspot, halo(s) and spill, "dirty" and clean (Block Party at bottom-right)

*All shots exposed at hotspot, for pattern-comparison purposes. the above is not intended to compare output power and all lights shot at lowest power-modes.

One of my other hobbies is sports & tactical cutlery. This short pictorial-essay what-have-you is geared towards the cutlery crowd, with the assumption that their knowledge of LED-tech is on average, on par with mine. I doubt that will be the case here at LPF, where most have been enjoying this both Laser diode and LED science infinitely longer. So please take this into consideration when sifting through the text. Feel absolutely free to correct me if/where necessary - I'm always eager to learn more! Worst case, the photos are pretty good...

:beer:

Fanatic about Photons

Fred, aka Photonfanatic over in CPF has been “playing with” things that go bright in the night for quite some time now and a few years back, started to admire the work custom knifemakers were doing and the materials they were investigating to push the art forward. Fred is no stranger to base metals & alloys, having made numerous [flashlight] hosts from stainless, aluminum and Titanium too. He anodized the Titanium, splashed the aluminum, bead-blasted / polished and coated just about everything (using just about everything - PVD, DLC, …).

(above photos c/o Photonfanatic)

Fred, being well, “Fred”, wasn’t satisfied making functional art out of just these materials and decided to try his hand at various forms of damascus. There was Mokume Gane (bi / tri-color, using nickel / copper), then came a wave of Chad Nichols' awesome stainless Damascus (nickel & SS). Once he was done with "plain" damascus, he gave mosaic damascus a try and created something so special that it’s making it’s way around the Country to get photographed

(above photos c/o Photonfanatic)

Next step in the evolution

After having admired his work for some time now, particularly with his enthusiasm to try out new materials, I asked him about his thoughts on the various Welded Titanium alloys in use by the knife-making community. Little did I know that thanks to co-damascus-fanatic Scott (aka ScottN in the cutlery community), Fred already had organized to get a bar of Chad's MokuTi! Well that certainly got me excited, not to mention Fred had already planned to make a WIP out of it

Click-the-pics for hi-res goodness.

Mad Skillz

If it hasn't dawned on you yet, Fred has a good eye for design and the skills to bring that design from his mind into reality. Amazingly, Fred uses very few machines compared to the average modern knifemaker and (naturally), the machines are geared toward cylindrical objects (you won't find a flat grinder in Fred's shop - heck not even sure he has a "grinder"... hand-polishing, definitely

New horizons

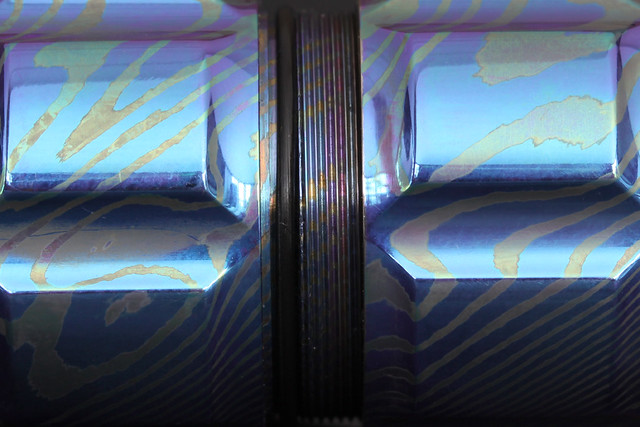

With every new material comes new adventures; some involve minor effort (material density, hardness etc.) others present interesting challenges. Making Mokuti colorful is one of the latter, as Fred soon found out! Just sifting through his WIP reveals how many color variations you can achieve by changing a few variables, like solution, voltage and yes, even surface finish (matt, polished, ultra-polished...). As I was following his WIP with great interest, I occasionally suggested some color-combos that I thought would be cool; I mentioned Warren Thomas' amazing Alien skin and the color tones he gets out of his [6AL4V] Ti work; I hinted at what Allen Elishewitz had done for me, coming up with some gorgeous MokuTi bolsters (pictured in the last section) and so on.

After a few weeks of experimentation, Fred did manage to sort out what variables would produce certain color ranges but just as importantly, he learned what many a knifemaker already knew, Mokuti is a beautiful, exotic and unpredictable creature. One can aim for a color-range, but that's as close as you will get with Mokuti; Titanium is not as predictable as the Nickel and steel found in classic damascus...

Base colors are blue and gold, "interference" colors are purple and green...

Mad eSkillz

Fred's hosts are some of the most creative and artistic in the customs-flashlight arena, but he doesn't make hosts, he makes handheld flashlights. Not just any flashlights, but state of the custom-world art ones. The Block Party may be stunning to look at, but it is a formidable powerhouse of a light too. First off, some specs:

Host: Chad Nichols MokuTi - welded Titanium (Ti alloy & Commercially Pure Ti), Solution anodized

Length: 120mm (4.7"), diameter: 25mm (1.0")

Weight: 170g (6.0oz) - including 47g 18650

Emitter: Cree XM-L (U2 bin) mounted on a 2mm thick MCPCB (Copper base)

Driver: Three-mode regulated (140mA, 1A, 2.8A), memory mode

Power Source: 18650 Rechargeable 3.7V battery (1)

Reflector: 20mm Khatod, stippled (orange peel)

Output: < 500 lumens (before glass)

Operation: "Twisty"

Other: O-ring seals for water resistance, 2mm-thick mineral glass, silicone gasket (instead of commonplace spring)

While I am no expert in the area of LED flashlights, I'm familiar with the basic principles and will review them for those with a heavier background in knives. Every light has a specific design in mind; illumination of a broad area, of a target area, or a bit of both. This is controlled by several design aspects of a light; the LED type (Emitter), reflector shape, length and surface and the glass ("window"). These properties also affect total / perceived output, along with the driver (which supplies constant current to the emitter) and power source (battery).

Fred has jumped on the XM-L bandwagon, an emitter that has taken the custom community by storm, thanks mainly to both its efficiency and output capability. Coupled to a relatively hi-current driver, capable of delivering up to 2.8A to the emitter and powered by a 3.7V Li-Ion, Fred's "Light Engine" (LE) can put out an estimated 500 Lumens. In comparison, the typical tactical handheld is rated around 200~250 lumens and classic "incans" (incandescent lights) are rated usually around 60 lumens. Thus, a 500-lumen handheld will certainly light up the neighbor's house...

Which brings us to the User Interface (UI). Most modern handheld lights use a side-button or a tail "clicky" or in the simplest form, are controlled by twisting the head ("twisty"). While Fred has done all of those, his philosophy is less is better. In other words, less moving parts provide for a more reliable solution. Simply twist the head clock-wise to turn it on, off/on within 1s "toggles" through the three modes. Once left on in any given mode for more than 2s, the driver will "remember" the mode the next time your turn on the light. Keeping in line with this minimalist principle, there are no springs in use; instead, a silicon gasket assures that battery remains secured. Fred's tolerances don't allow for much play anyways...

The illumination pattern of a flashlight generally consists of the hotspot, halo and Spill. Fred chose to make this one a "Wall of light" by using a stippled reflector of a shallow(er) depth. This in turn produces less of a prominent spot and enhances the spill. Thus you have a light that has good flood characteristics (wide angle of illumination), but less throw or reach (illumination distance). I happen to find this setup both unique and useful, not to mention aesthetic. Thanks to both Fred's build accuracy and chosen setup, the so-called halo is almost unnoticeable. If you've ever used an El Cheapo $15 LED handheld, then you know how drastic the contrast can be between the hotspot and spill, causing a high-contrast ring (and sometimes, even multiple rings... :rant:

Perfectionist

So far so good. Or maybe not. Fred apparently was not impressed with the fit & finish of the driver, noting that there were visible electronic components on the battery-side as the designers wanted to shave off an additional pcb layer ...sigh. So Fred, being, well "Fred", took it upon himself to correct this by machining a piece of delrin to cover the exposed electronics. Furthermore, he decided the factory-installed spring was crap, so he replaced it with a brass button. So when I say this is a custom light, I do damn well mean custom in every possible way... :bowdown:

(above photos c/o Photonfanatic)

Every rose has it's thorn

Or something like that (it's been a while since I was in English Lit. ...) The multi-mode driver used in this build uses a technology known as Pulse-Width Modulation (PWM). Unfortunately PWM has a few side effects when using the light in any mode other than high. The first is the fact that the light flickers at some (high) frequency. The second problem is that a PWM system can cause an audible "whine" (as recorded in this video). I cannot notice any flicker however I do hear the whine. The sound is barely noticeable in low but readily apparent in medium, assuming a quiet environment (like your basement, etc.) Fred, being well, "Fred", is looking at alternative drivers and trying to determine their operating frequencies, etc.

The only other possible area of concern is the heat output of an LED like the XM-L driven at 2.8A. When the light is on high, it will warm up in no time. After approx. 1min, the head will heat up to an uncomfortable level. This is normal for hi-powered handhelds and you will often see a warning sticker on the heads. Having foreseen the need to cool this emitter, Fred made the host longer then his usual 18650 hosts (120mm vs. 100mm) and housed the emitter and driver in a beefy Al heatsink. While it is hard to imagine a more attractive host, MokuTi or simply, titanium, is not the best material for head-dissipation. In general, Ag, Cu & Al are considered the best thermal conductors, with Al being the most popular due to its price/efficiency ratio.

Time will tell if operating such a high-powered Light Engine in such a sleek host will be feasible. In terms of real-world usage, Medium (@1A output and moderate heat emission) is the more useful mode, with high being only necessary in very rare circumstances (like showing the light off... :eg: ). The Block Party is primarily functional art and not intended for extreme operating environments (no tour-of-duty planned for this puppy

Conclusion

Functional art is what Fred is all about; from the design principles, to the precision engineering and the desire to produce the very best that he can. This is what got my attention in the first place and this has only been reaffirmed now that I've had the pleasure to use and enjoy Fred's latest masterpiece, the Mokuti Block Party!

:beer: :beer: :beer: :beer: :beer:

Precision-engineering, inside and out...

A MokuTi...

...Chameleon...

...in shades of blues, gold, purples and greens

Typical forms of illumination patterns*, from throw to flood, hotspot, halo(s) and spill, "dirty" and clean (Block Party at bottom-right)

*All shots exposed at hotspot, for pattern-comparison purposes. the above is not intended to compare output power and all lights shot at lowest power-modes.