JLSE

1

- Joined

- Dec 13, 2007

- Messages

- 3,580

- Points

- 0

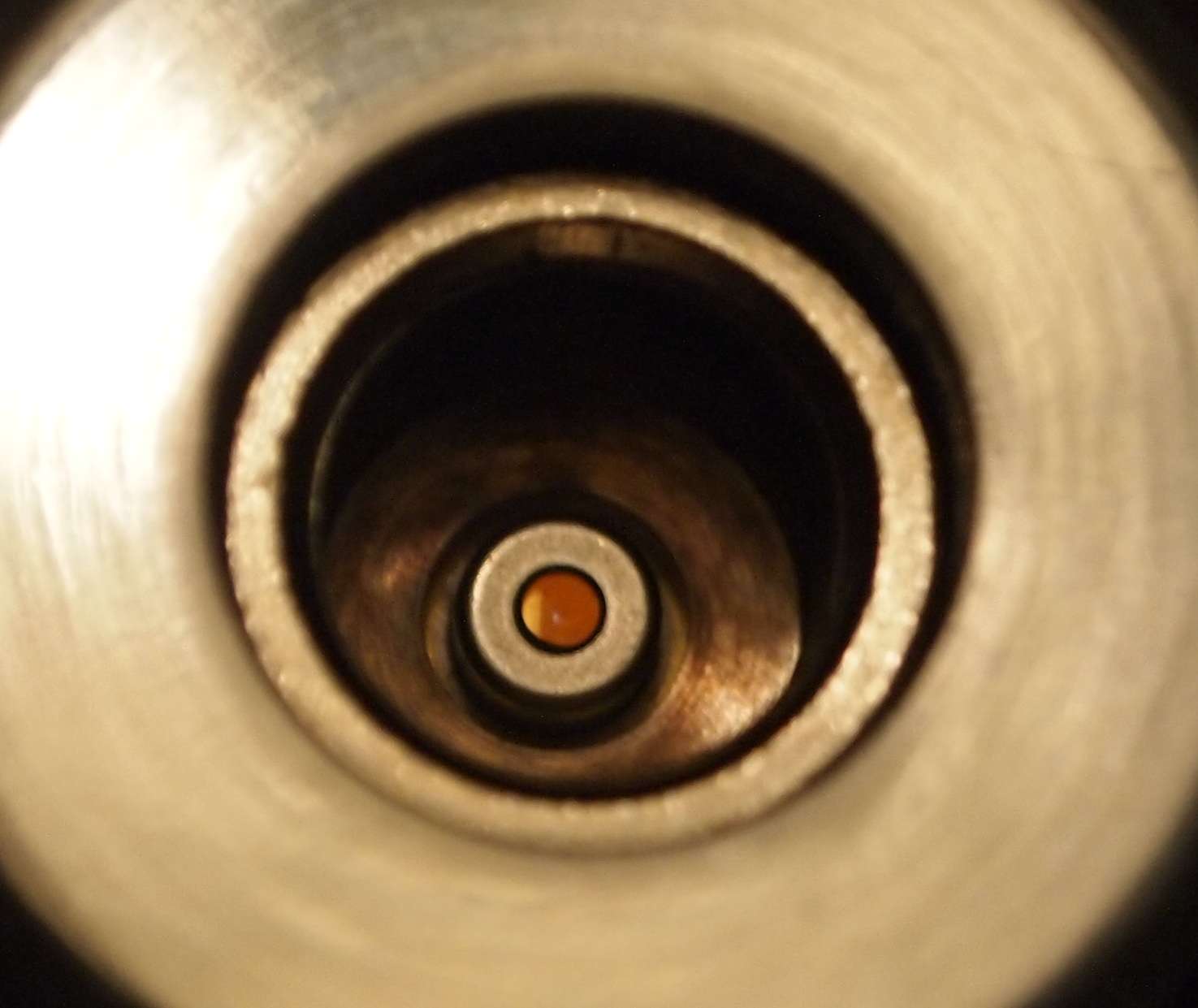

At first I didnt pay much attention to it, but I noticed it

too many times, and that got me thinking..

Has anybody else noticed what looks to be a 'burn' mark

in the shape of the output on your 445nm LD's??

It looks as if the laser is burning the AR coating and leaving

a very distinct mark on the window.

Have a look at the center of this diode, and if you have a 445nm

LD on hand, check yours with a magnifier..

An interesting note, the sides of this line seem to be more pronounced.

Where as the center looks less distorted.

Could the location of the seemingly more affected area also be responsible

for the 'noise' on the edge of a collimated large dot when viewed on the wall??

Im making a decanned 445 now, and will see if removing the can eliminates

any of the artifacts on the edges of the beam..

too many times, and that got me thinking..

Has anybody else noticed what looks to be a 'burn' mark

in the shape of the output on your 445nm LD's??

It looks as if the laser is burning the AR coating and leaving

a very distinct mark on the window.

Have a look at the center of this diode, and if you have a 445nm

LD on hand, check yours with a magnifier..

An interesting note, the sides of this line seem to be more pronounced.

Where as the center looks less distorted.

Could the location of the seemingly more affected area also be responsible

for the 'noise' on the edge of a collimated large dot when viewed on the wall??

Im making a decanned 445 now, and will see if removing the can eliminates

any of the artifacts on the edges of the beam..