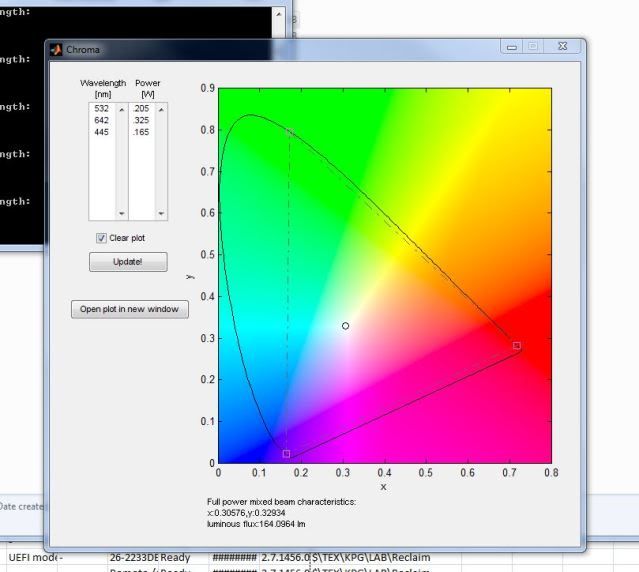

Thanks.. It looks like both blue and green need to decrease a bit on that plot.

My guess is that 150ish mw of 642 will be about the same as the output I get from a cheap LOC from a dvd burner. Hmm... tho the dvd diode would be running way over spec, and the 642 wouldn't be..

I'll go w/ the LOC for now.. That'll leave room for a future upgrade.

My guess is that 150ish mw of 642 will be about the same as the output I get from a cheap LOC from a dvd burner. Hmm... tho the dvd diode would be running way over spec, and the 642 wouldn't be..

I'll go w/ the LOC for now.. That'll leave room for a future upgrade.