- Joined

- Jun 7, 2012

- Messages

- 1,683

- Points

- 63

After searching LPF for discussions concerning heat sink materials, I've seen several members mention that aluminum outperforms copper for the purpose of heat removal. This part is for you.

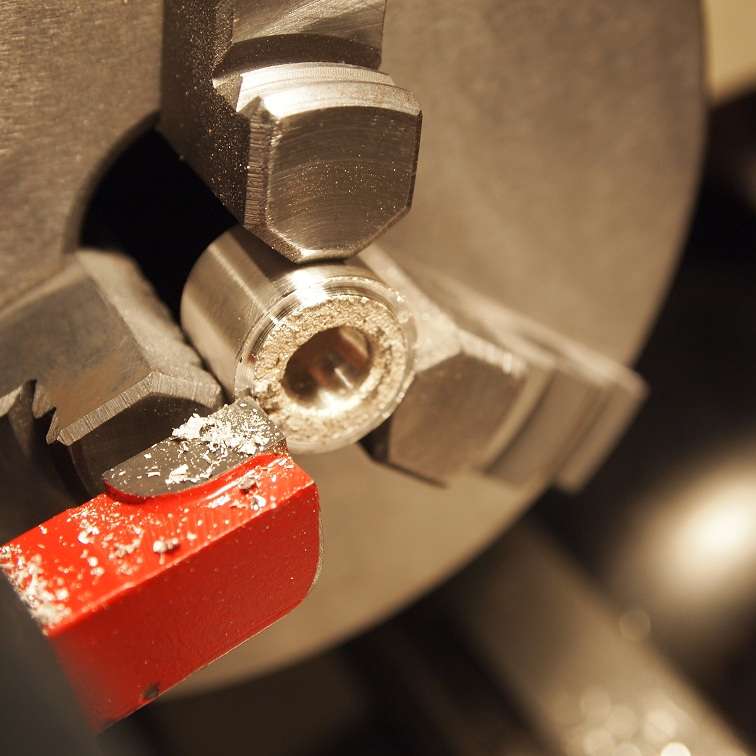

Simply put, copper outperforms aluminum in every way for the purpose of removing heat. Aluminum in many cases is used instead of copper because it costs less, is lighter, can be anodized to any color, and it can be extruded where copper cannot. Comparing the volumetric heat capacities of Al and Cu shows that when energy is applied to similar sized heat sinks, for every 1°C copper rises aluminum will rise 1.4°C, and similarly for every 1°F copper rises aluminum will rise 1.4°F. Ignoring thermal conductivity and comparing duty cycles, copper will run 40% cooler than aluminum and give an overall +40% to runtime. When you consider copper's thermal conductivity that's about twice that of aluminum, copper is much better suited to protect laser diodes from heat than aluminum.

Comparing Copper to other metals

There already is a good thread created my rhd that discusses heat capacity vs conductivity and how copper might not be the best heat sink choice.

http://laserpointerforums.com/f54/i-want-copper-copper-copper-well-maybe-not-72698.html

He brings up a very good point. When a diode heats up the heat sink, it's limited by how much heat it can dissipate to the air around it and that materials like iron, steel, or nickel could be better options for a heat sink than copper. Although I appreciate the analysis I don't agree with it. Using materials like iron or steel will give the heat sink a higher heat capacity, but they have a much lower thermal conductivity, about 5 times less than that of copper. A diode creates a very small hot spot inside of a host, and removing heat from such a small spot calls for material with a high thermal conductivity like copper to draw the heat away to other parts of the heat sink and host. When it comes to heat sinking thermal conductivity is very important.

Steel will take more energy per degree change, but it will conduct the heat away much more slowly than copper. The heat distribution in steel will hold more heat near the diode where copper will distribute it more evenly keeping the diode cooler. Steel will actually provide a shorter duty cycle because it does not move heat away fast enough, and you wouldn't know until it's too late because the inside of the host remains much hotter than the outside. An example of this in computer processing applications is addressed in this link by a thermshield engineer. Where there are "hot spots" ,copper is preferred to move heat away quickly. Thermal conductivity is a very important characteristic in continuously cooled operations and even more so in passively cooled systems like handheld lasers. Where the host can be looked at as the heat sink fins.

http://www.thermshield.com/ThermshieldPages/Copper_vs_Aluminum.pdf

Laser diodes create hot spots and need heat to be moved away quickly. In the previously mentioned thread it was noted that you want to avoid heat choke points in builds, and that putting a copper axis module in a steel sink would be a good idea. That would be placing a choke point around the module causing extra heat build up and not be better than using solid copper.

With copper's nearly unmatched thermal conductivity and respectable heat capacity, it's the best metal for nearly all heat sinking, but especially for laser diode applications.

Simply put, copper outperforms aluminum in every way for the purpose of removing heat. Aluminum in many cases is used instead of copper because it costs less, is lighter, can be anodized to any color, and it can be extruded where copper cannot. Comparing the volumetric heat capacities of Al and Cu shows that when energy is applied to similar sized heat sinks, for every 1°C copper rises aluminum will rise 1.4°C, and similarly for every 1°F copper rises aluminum will rise 1.4°F. Ignoring thermal conductivity and comparing duty cycles, copper will run 40% cooler than aluminum and give an overall +40% to runtime. When you consider copper's thermal conductivity that's about twice that of aluminum, copper is much better suited to protect laser diodes from heat than aluminum.

Comparing Copper to other metals

There already is a good thread created my rhd that discusses heat capacity vs conductivity and how copper might not be the best heat sink choice.

http://laserpointerforums.com/f54/i-want-copper-copper-copper-well-maybe-not-72698.html

He brings up a very good point. When a diode heats up the heat sink, it's limited by how much heat it can dissipate to the air around it and that materials like iron, steel, or nickel could be better options for a heat sink than copper. Although I appreciate the analysis I don't agree with it. Using materials like iron or steel will give the heat sink a higher heat capacity, but they have a much lower thermal conductivity, about 5 times less than that of copper. A diode creates a very small hot spot inside of a host, and removing heat from such a small spot calls for material with a high thermal conductivity like copper to draw the heat away to other parts of the heat sink and host. When it comes to heat sinking thermal conductivity is very important.

Steel will take more energy per degree change, but it will conduct the heat away much more slowly than copper. The heat distribution in steel will hold more heat near the diode where copper will distribute it more evenly keeping the diode cooler. Steel will actually provide a shorter duty cycle because it does not move heat away fast enough, and you wouldn't know until it's too late because the inside of the host remains much hotter than the outside. An example of this in computer processing applications is addressed in this link by a thermshield engineer. Where there are "hot spots" ,copper is preferred to move heat away quickly. Thermal conductivity is a very important characteristic in continuously cooled operations and even more so in passively cooled systems like handheld lasers. Where the host can be looked at as the heat sink fins.

http://www.thermshield.com/ThermshieldPages/Copper_vs_Aluminum.pdf

Laser diodes create hot spots and need heat to be moved away quickly. In the previously mentioned thread it was noted that you want to avoid heat choke points in builds, and that putting a copper axis module in a steel sink would be a good idea. That would be placing a choke point around the module causing extra heat build up and not be better than using solid copper.

With copper's nearly unmatched thermal conductivity and respectable heat capacity, it's the best metal for nearly all heat sinking, but especially for laser diode applications.