- Joined

- Jun 24, 2010

- Messages

- 5,705

- Points

- 113

3W Menace

Ok so I have had this host for almost a year now. I kind of shelved it as I have been pretty busy and have had little time for some reviews but I have been really wanting to build this unit. I know there have been other builds on this host but this one really turned out amazing.

Host

This host is massive. About the size of the Frankenstein host I built. Here are some quick shots of the body.

It has a great feel holding it. I know my bear paws don't really give a good judge of the size.

So here is my favorite soda can comparison.

Build

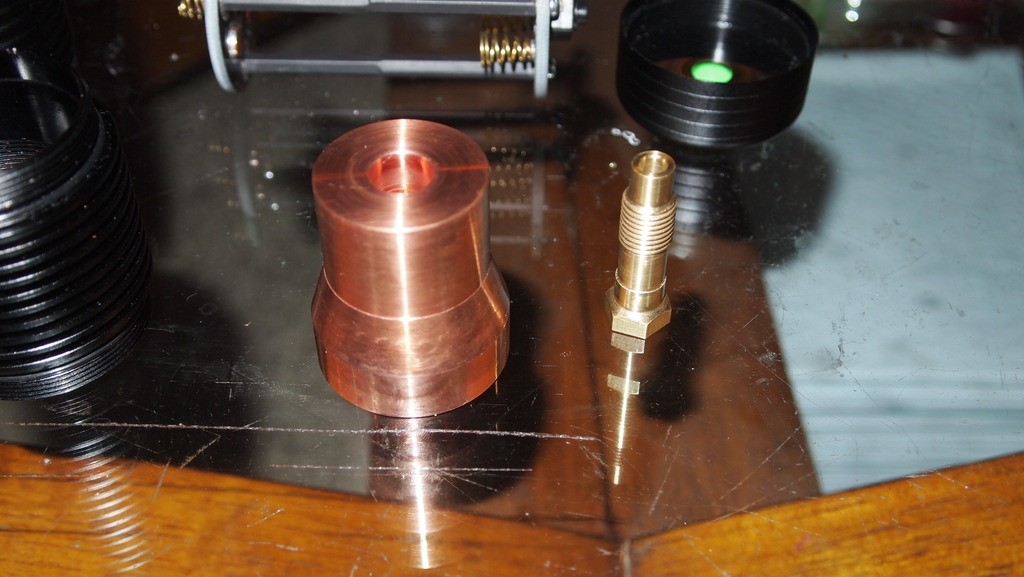

So I sent it off to Flaminpyro to fit for a heatsink and he suggested a full copper direct heatink for a 9mm. I agreed this build being my first in a while should go all out. When I got it back here is what I found.

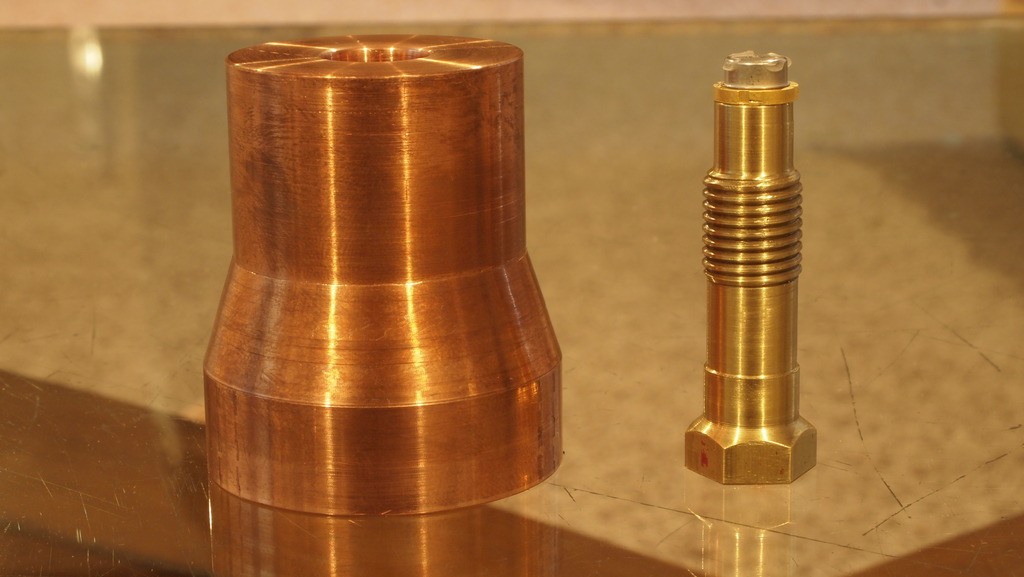

I was amazed at the heatsink size. It weighs over a pound of solid copper. He also included a sweet press to keep the diode in place in the heatsink and it allows for some amazing heastinking on this diode.

So I got a 9mm diode and placed it on the press to see how it goes.

I screwed it in to see how the diodes fits and it is a great fit but I noticed that I did not have much room left on the back of the heatsink for sticking the driver on with the press sticking out.

So I lopped off the end and put some slots in for a flat head to turn it.

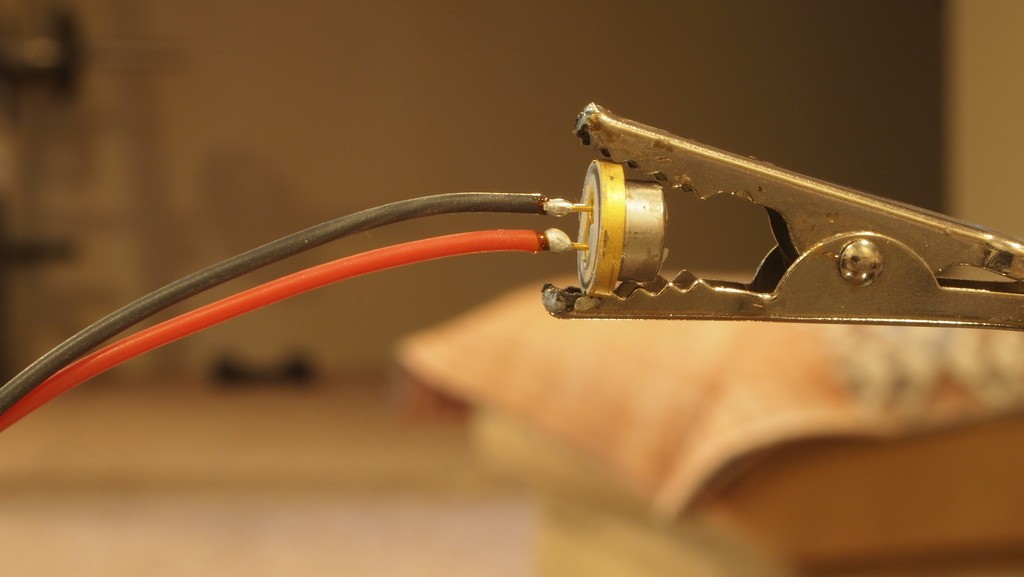

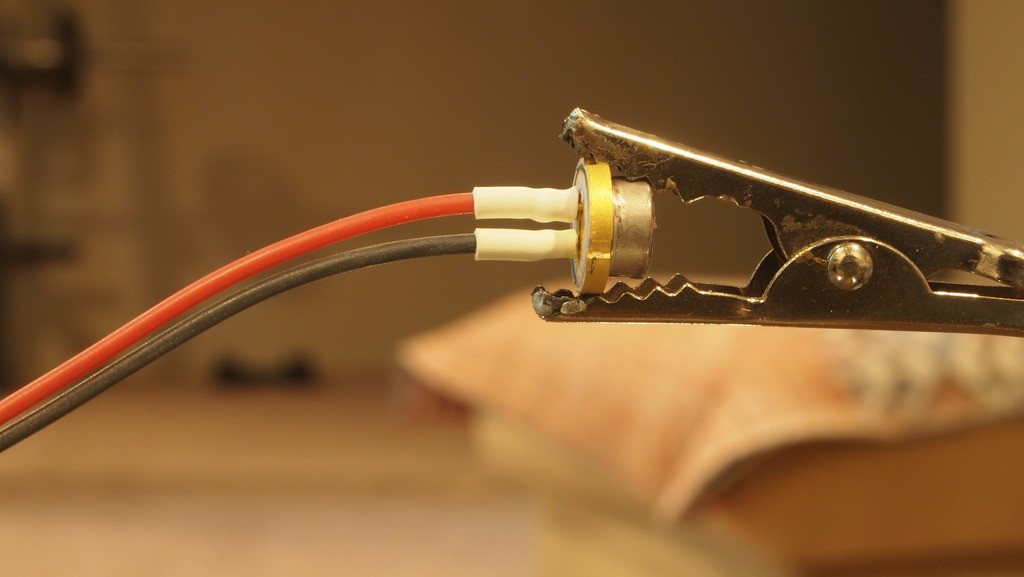

Next I added some leads to the diode.

Then put some shrink tubing over the pins to keep them nice and protected.

So now I put the unit back in the heatsink and screwed the press down tight on the diode. This leaves me some good space on the back of the sink to adhere the driver to.

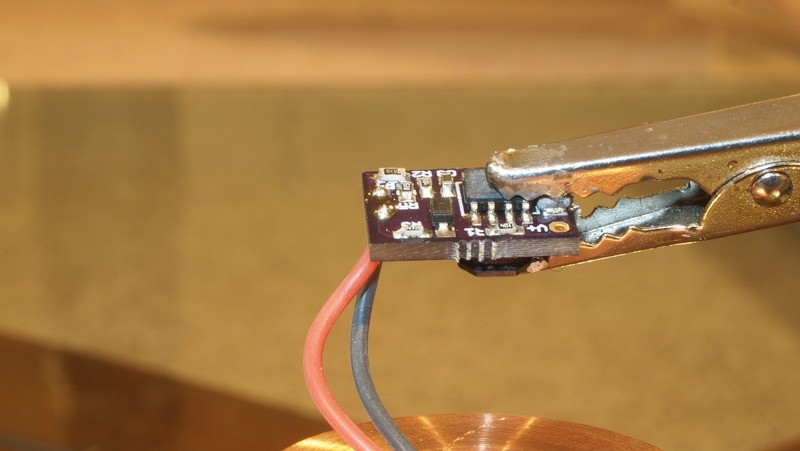

Next I stripped the leads, added a small amount of flux and fed them though the driver holes. I am using an X-drive set to 2.2A. They X-drive is awesome. Low heat generation, very efficient and uses a soft start for long diode life.

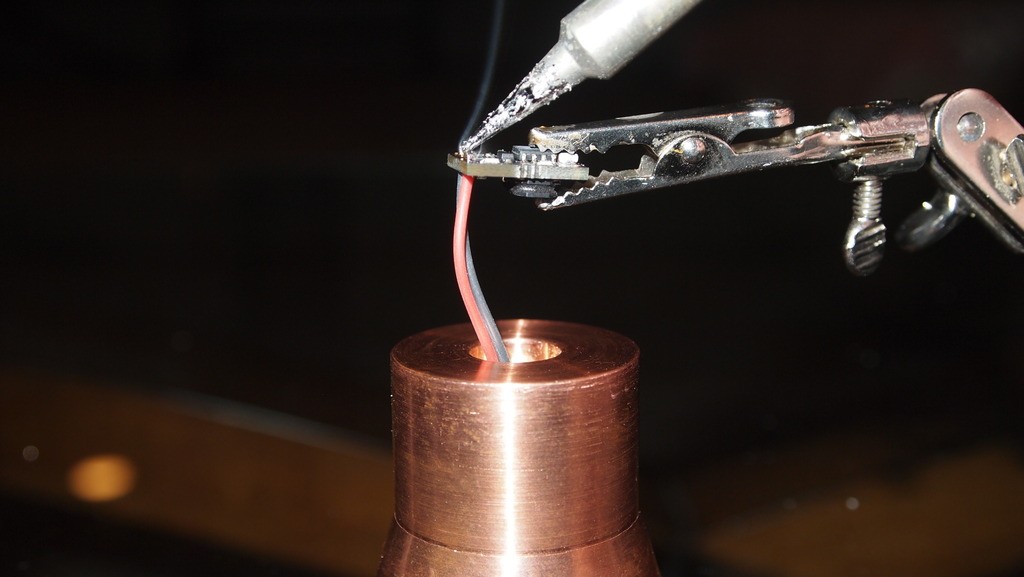

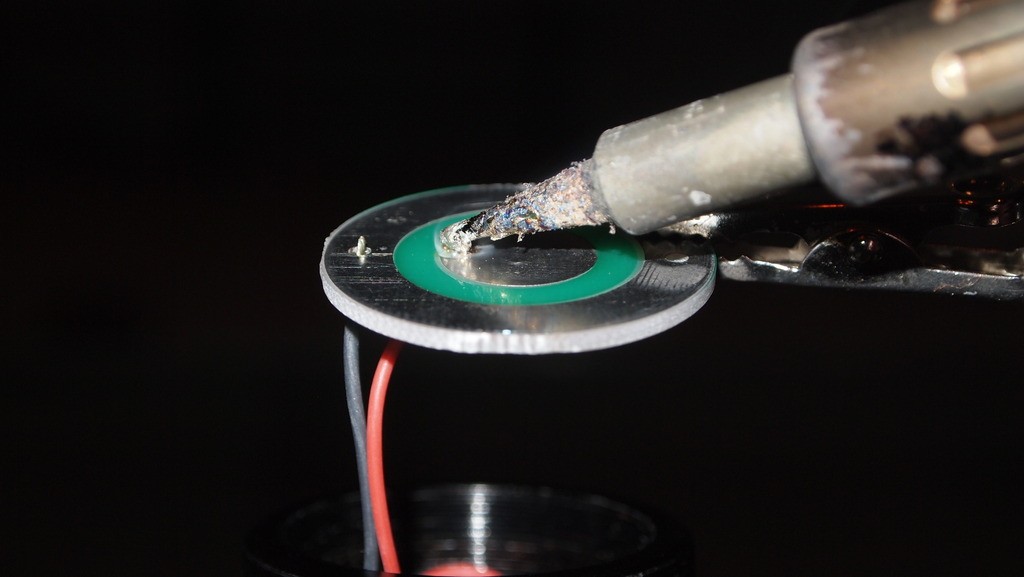

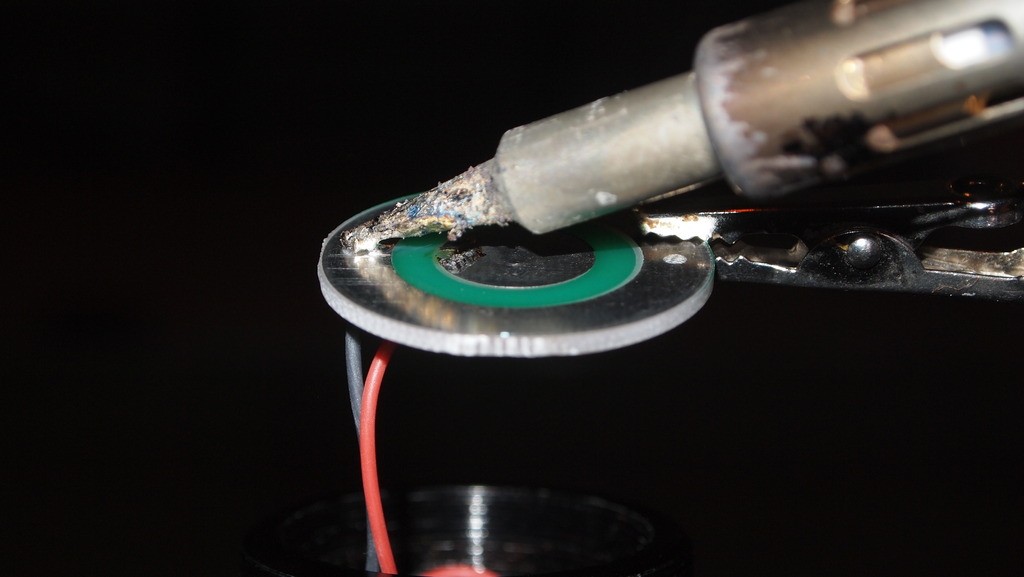

Next I soldered the leads in place.

Came out nice and clean.

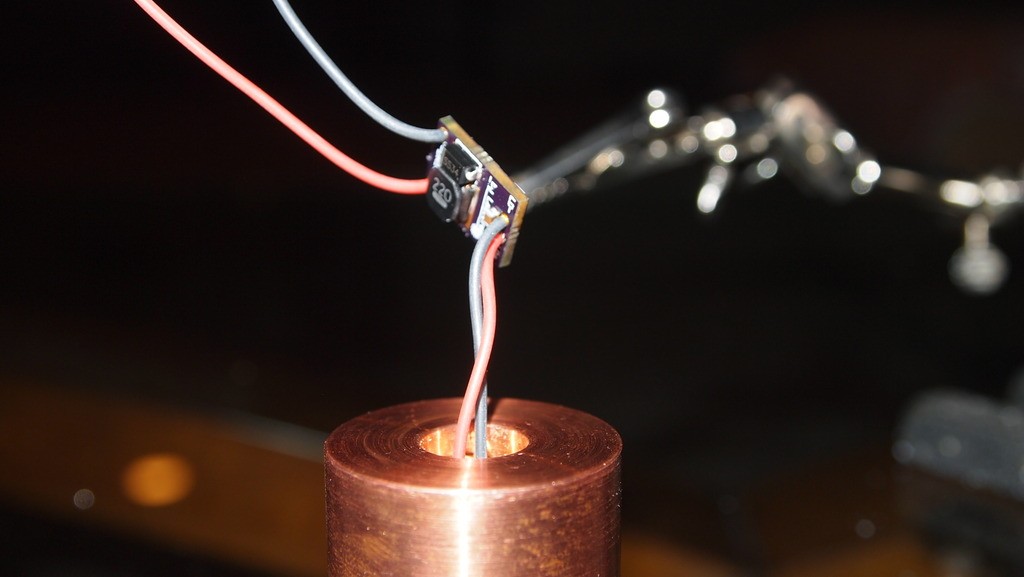

Next I soldered some leads on the driver input.

And it is ready for sinking the driver.

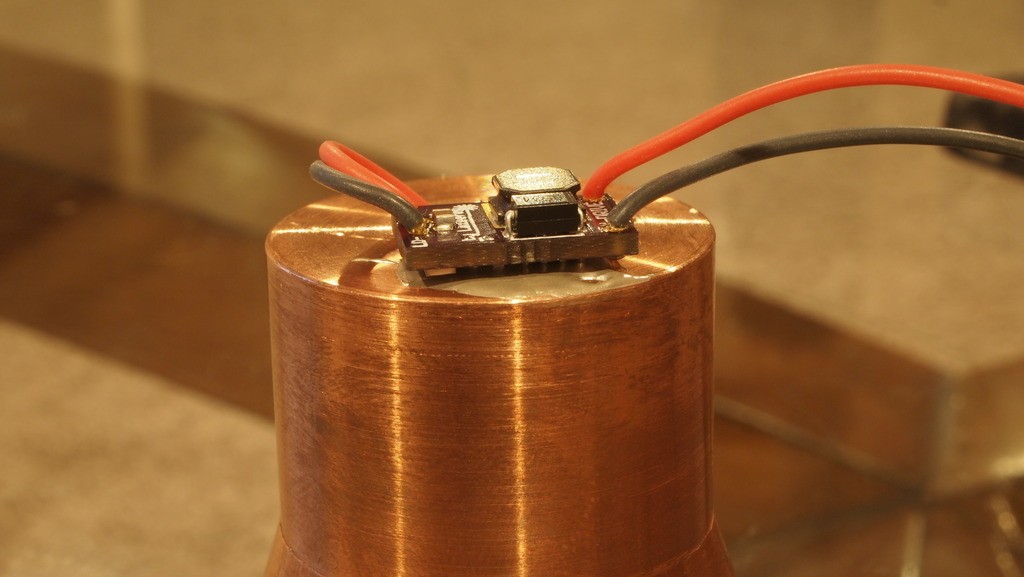

So I got some thermal adhesive out. I am using Arctic silver. I usually just use the Arctic alumina as I think it does just as well for our purposes and it is much cheaper but this was all they had at microcenter when I ran down there. So I went with it.

So I mixed up a small amount of the two part.

After mixing it up I applied a bit to the back of the heatsink.

I pressed the driver in place then used my helping hands to keep the pressure on it till it hardens.

Gave it 15 minutes and I was good to go.

Next put the heasink in the head and it fit like a glove.

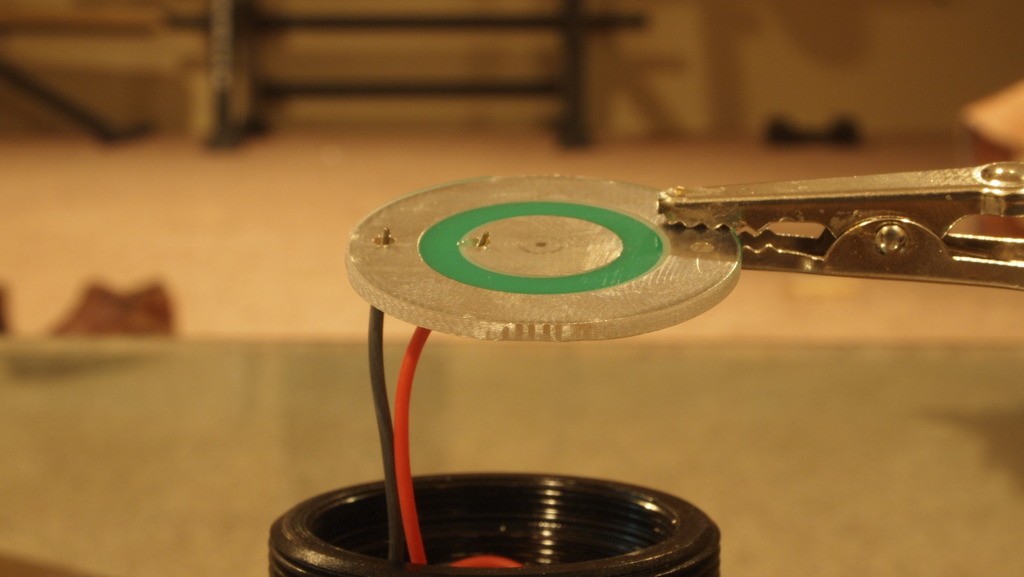

Now all that is left is the contact board. So again I stripped the ends of the leads, added a bit of flux and put the lead through the little holes for the wires.

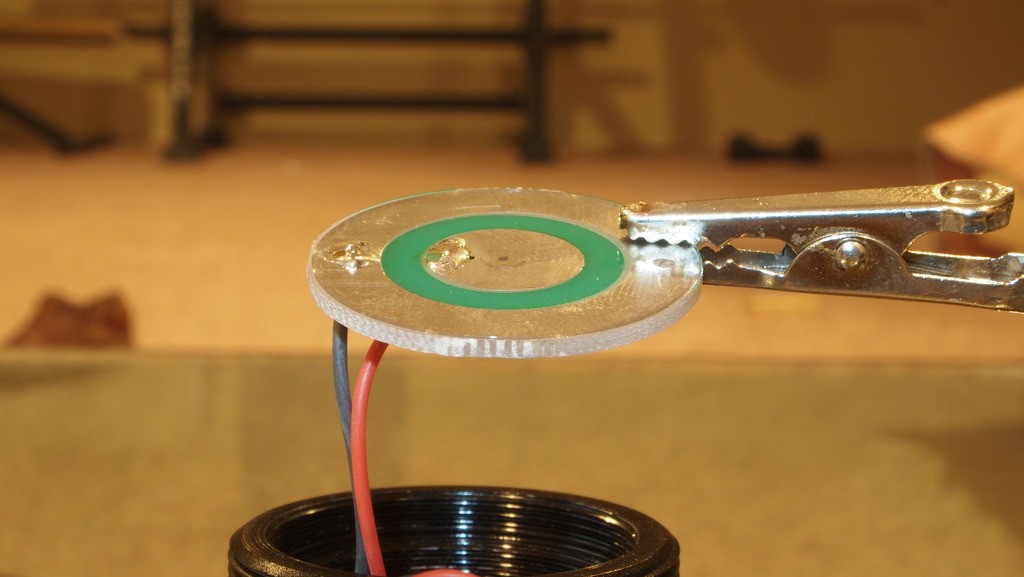

I put a bit of solder to secure the leads.

Now I am good to go and ready to seal it up.

I placed it in the head.

And tightend down the retaining ring.

Now here is the crazy part. I origonally thought the 3X18650 holder was wired in series but I quickly realized it was set up for parallel.

So I had to switch it up and it actually came out great. This host can now work of 2X, 4X or 6X 18350's. So I went with just two AW IMR 18350's I had laying around.

Power Test

So I put it all together and ran a test and I have to say this is the most stable laser I have ever seen and I am sure it all due to the amazing heatsink that Flaminpyro made for me. Check this out. 14+ minutes and only a 300mW drop in power. This thing is amazing and it has a peak just over 3W and this was not a cherry picked diode just a random pull plus it is using a G-2-LFL lens.:eg:

Conclusion

So I could not be happier with this unit. It has been a while since I have made a personal build and this one absolutely rocks. Massive, stylish powerful. 3W peak at 2.2A using a G-2-LFL you can't ask for more.

I give a lot of credit to Jeff(Flaminpyro) for the stability and peak power of the unit due to the great heatsink he made for this thing.

Anyway that is about it hoped you like seeing my newest build. Thanks for reading.:beer:

.

Last edited: