Hello all, building my first laser. HOORAY ME! , Nice site you guys have here!

I did not like using idea of using the little driver boards out of the laser pointers. Instead I figured it would be better and a little more educational to make one.

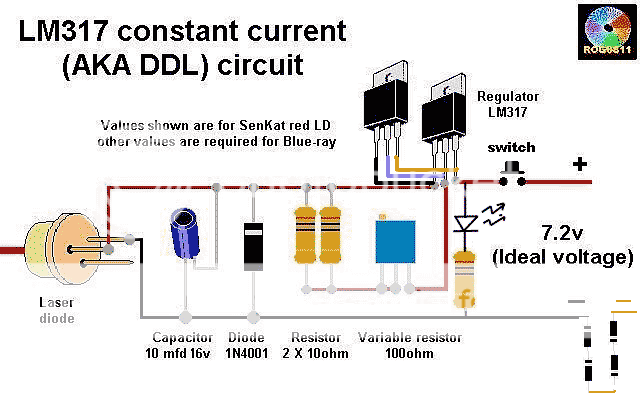

This is the one I have settled on, I like undertanding and being able to adjust the output with the resistors. With this, I will KNOW how much current is flowing to diode.

My electronics skills are very rusty, I'm gettin old.

The above is simple enough, but I would like to add an on/off indicator light(green/red diode).

I'm not sure where to put it in the circuit.

could I put it in place of the 4001, with a 330-470ohm current limiting resistor??

Advice...thanks

I did not like using idea of using the little driver boards out of the laser pointers. Instead I figured it would be better and a little more educational to make one.

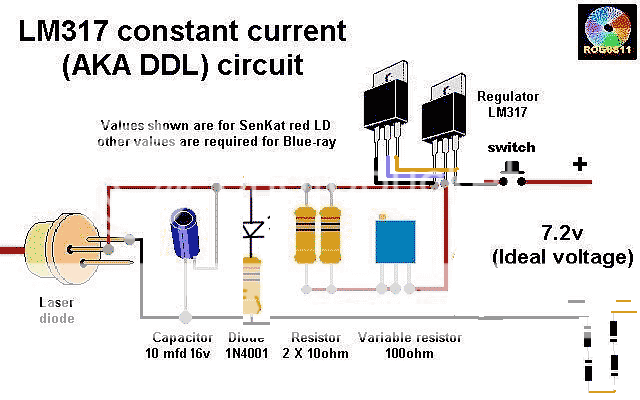

This is the one I have settled on, I like undertanding and being able to adjust the output with the resistors. With this, I will KNOW how much current is flowing to diode.

My electronics skills are very rusty, I'm gettin old.

The above is simple enough, but I would like to add an on/off indicator light(green/red diode).

I'm not sure where to put it in the circuit.

could I put it in place of the 4001, with a 330-470ohm current limiting resistor??

Advice...thanks