GBD

0

- Joined

- Oct 25, 2010

- Messages

- 783

- Points

- 0

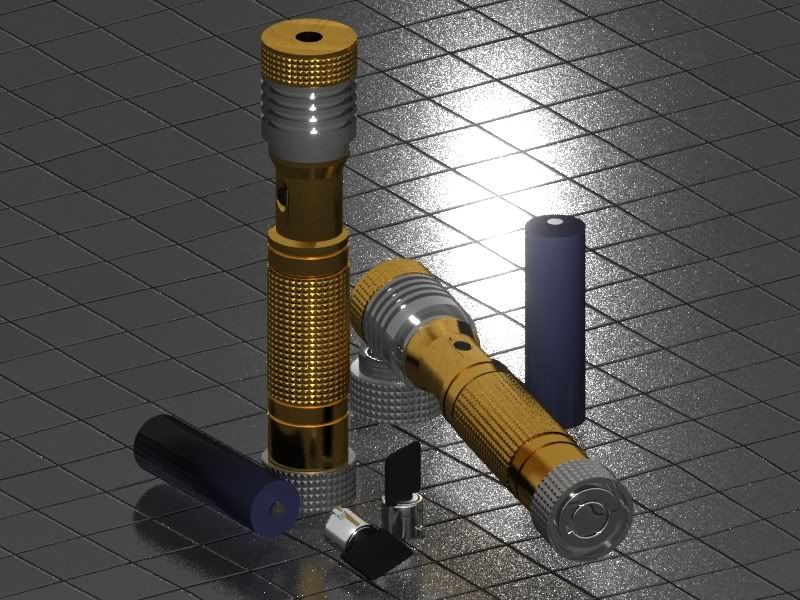

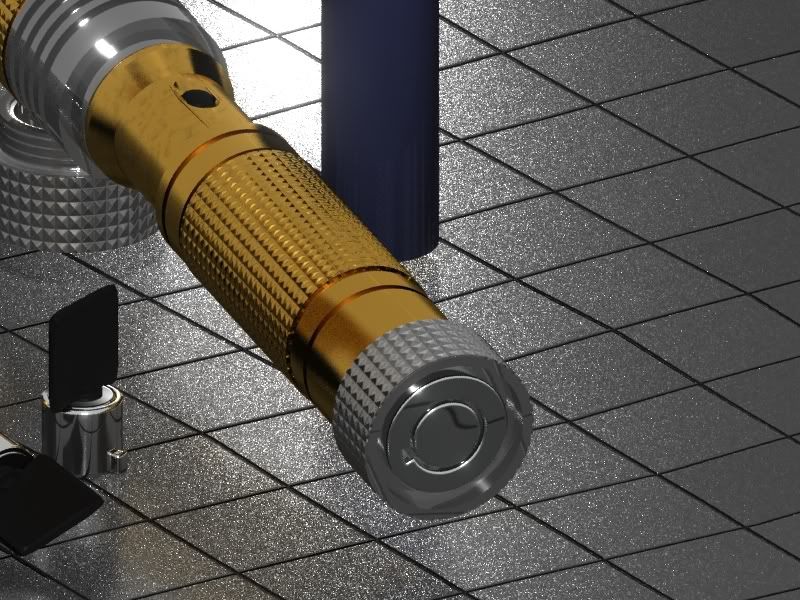

Ive recently finished a quick red diode module. its lasing quite nicely, but it needs a host.

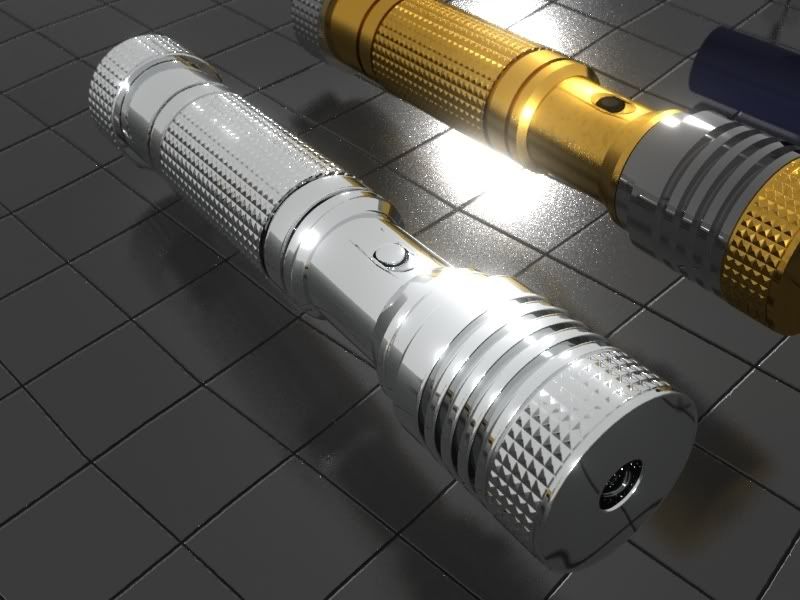

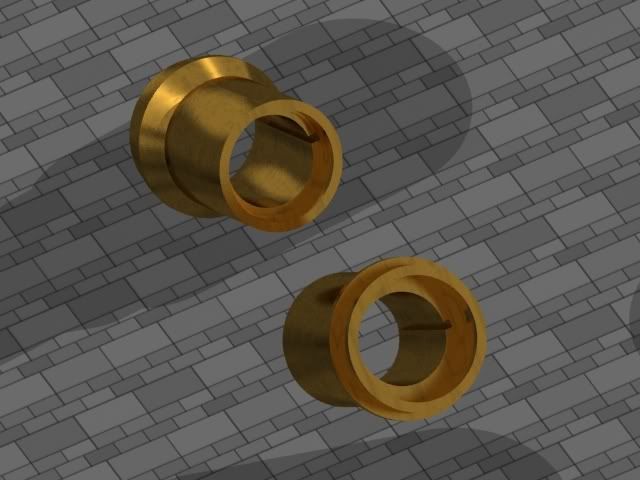

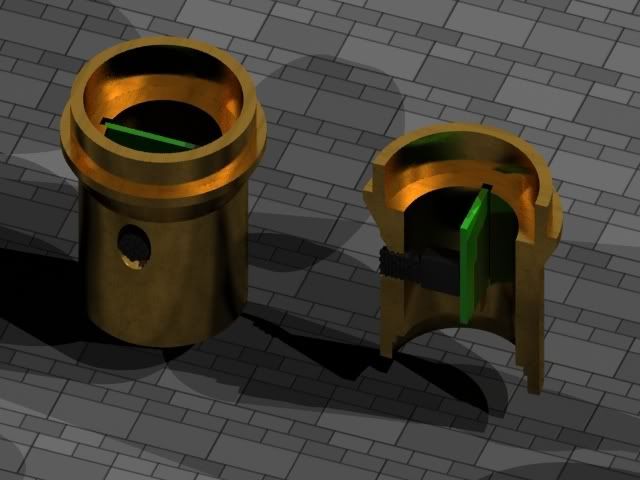

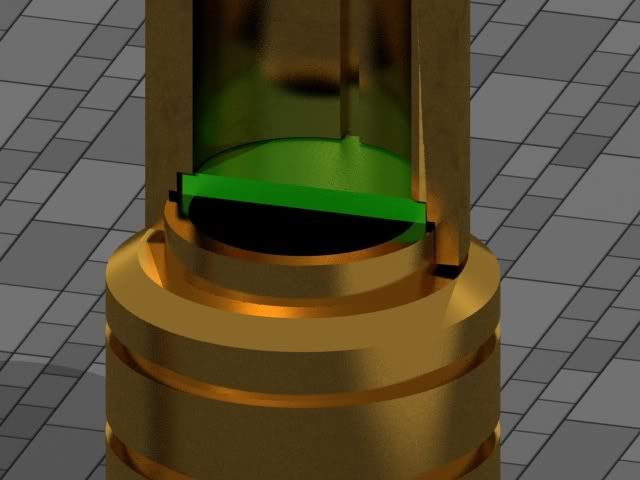

This is probably also the first time ive even put a red into a handheld, so I am going to make a host for it which will more or less look something like this:

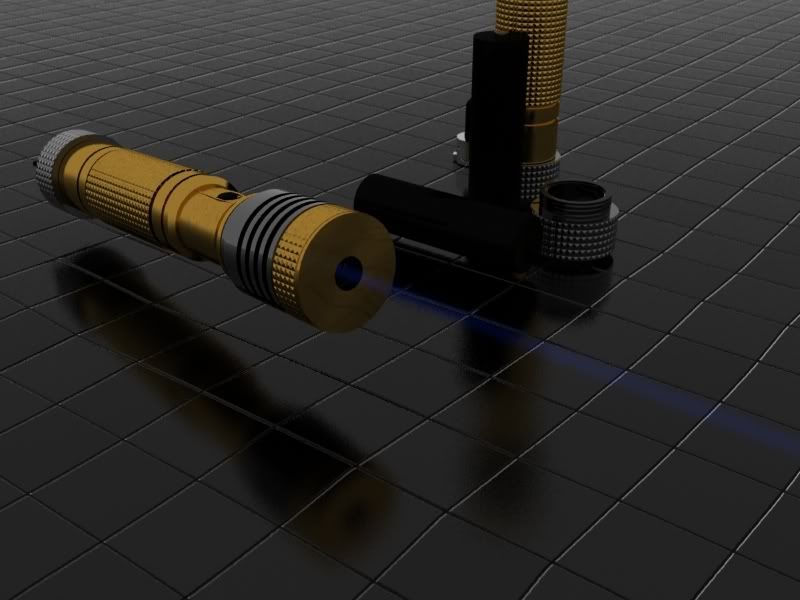

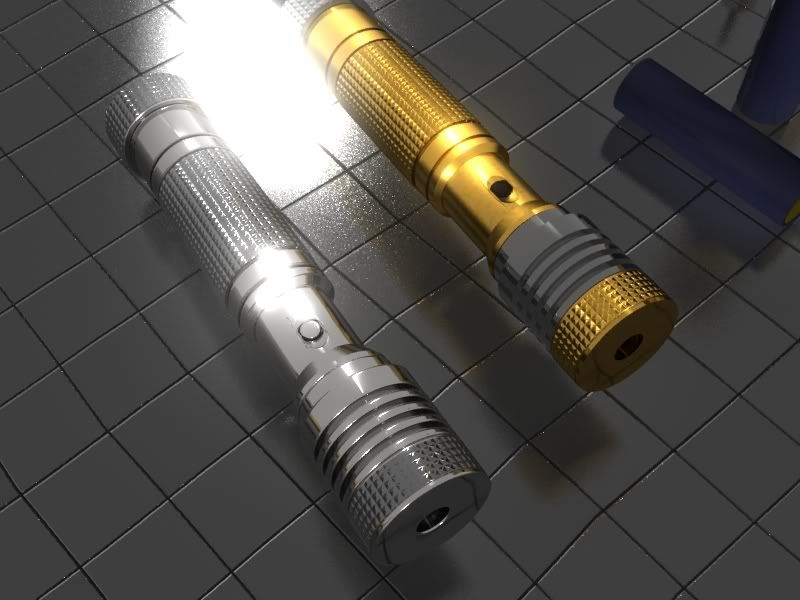

I am wondering how to finish it (paint job wise) for its final look, and I am stuck between these three:

(Please excuse the crudly drawn MS paint pictures)

1. Partially anodized (either gloss or matte black), the gray represents exposed aluminum that will be polished.

2. No anodization at all, all polished aluminum.

3. Full anodized (either gloss or matte black)

If you think all of these designs suck, please let me know and Id love to hear up some ideas of your own.

Im stuck between these three, and would like some advice.

Thanks.

:beer:

This is probably also the first time ive even put a red into a handheld, so I am going to make a host for it which will more or less look something like this:

I am wondering how to finish it (paint job wise) for its final look, and I am stuck between these three:

(Please excuse the crudly drawn MS paint pictures)

1. Partially anodized (either gloss or matte black), the gray represents exposed aluminum that will be polished.

2. No anodization at all, all polished aluminum.

3. Full anodized (either gloss or matte black)

If you think all of these designs suck, please let me know and Id love to hear up some ideas of your own.

Im stuck between these three, and would like some advice.

Thanks.

:beer:

Last edited: