As I mentioned over in Gas Lasers... I have wanted to do Holography for about 15 years or more... I had build a concrete platform for my setup and then lost interest back in the day... Well, its time to get back to work!

Here is the table as it sits:

Untitled by Christopher Purdy, on Flickr

Its basically right out of the old holography book (can't remember the name atm..) Concrete blocks holding up the table top... but I improvised to get more weight. I used 2'x2'x2" thick paver tiles as a base, and then poured 2" of concrete on top of that as well. Doubled up carpet separates all the layers.

I have been experimenting with DIY optical mounts. I came up with these by visiting the plumbing section of home depot. Basically, its a floor flange with three 1/4X20 holes drilled and tapped for leveling screws. Then a 2" nipple and a 90 degree bend. I then hot glued a DIY FS mirror to that.

This is an interferometer setup using these mounts.

Untitled by Christopher Purdy, on Flickr

The beam splitter is some hand cut plate glass per my other post. I milled a 1/8 inch slot in a cap and hot glued it in there, and then screwed it onto the 2" nipple.

The interferometer shows that it is rock solid... and recovers from a tap in well under a second.

All parts can be fully adjusted... albeit they are a bit sloppier than I would like... which leads me to my next project...

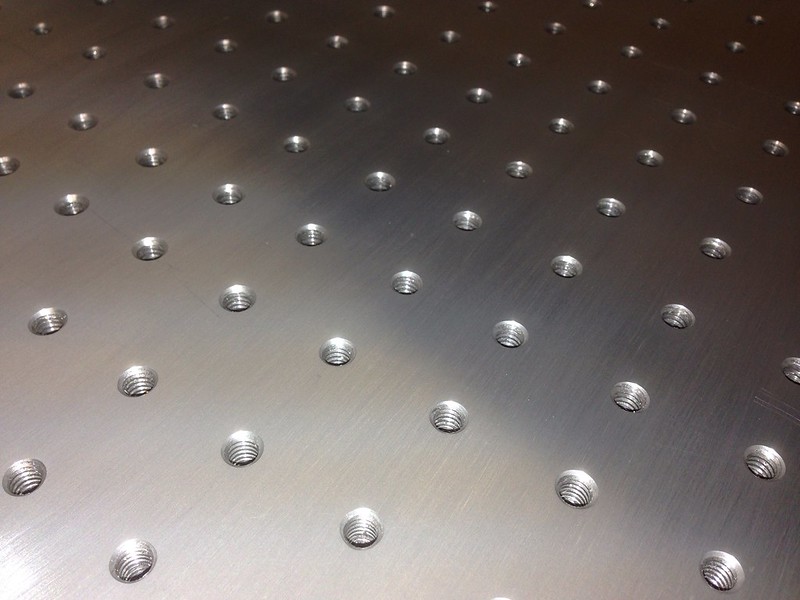

Have a look at this:

Untitled by Christopher Purdy, on Flickr

I procured an 18" X 18" X 1/2" thick aluminum plate from the scrap bin at work today. I have laid out a 1" grid of 1/4X20 holes... I got busy and drilled about 1/3 of them tonight...

The bad news is I will likely be hand tapping them as the thickness of the plate will snap the tap I fear if I chuck it in my drill... which is what I did with my last optical breadboard that was based on 1/4 inch thick plate..

I'll post updates as things progress..

Here is the table as it sits:

Untitled by Christopher Purdy, on Flickr

Its basically right out of the old holography book (can't remember the name atm..) Concrete blocks holding up the table top... but I improvised to get more weight. I used 2'x2'x2" thick paver tiles as a base, and then poured 2" of concrete on top of that as well. Doubled up carpet separates all the layers.

I have been experimenting with DIY optical mounts. I came up with these by visiting the plumbing section of home depot. Basically, its a floor flange with three 1/4X20 holes drilled and tapped for leveling screws. Then a 2" nipple and a 90 degree bend. I then hot glued a DIY FS mirror to that.

This is an interferometer setup using these mounts.

Untitled by Christopher Purdy, on Flickr

The beam splitter is some hand cut plate glass per my other post. I milled a 1/8 inch slot in a cap and hot glued it in there, and then screwed it onto the 2" nipple.

The interferometer shows that it is rock solid... and recovers from a tap in well under a second.

All parts can be fully adjusted... albeit they are a bit sloppier than I would like... which leads me to my next project...

Have a look at this:

Untitled by Christopher Purdy, on Flickr

I procured an 18" X 18" X 1/2" thick aluminum plate from the scrap bin at work today. I have laid out a 1" grid of 1/4X20 holes... I got busy and drilled about 1/3 of them tonight...

The bad news is I will likely be hand tapping them as the thickness of the plate will snap the tap I fear if I chuck it in my drill... which is what I did with my last optical breadboard that was based on 1/4 inch thick plate..

I'll post updates as things progress..

Last edited: