- Joined

- Mar 20, 2013

- Messages

- 126

- Points

- 18

Hi all,

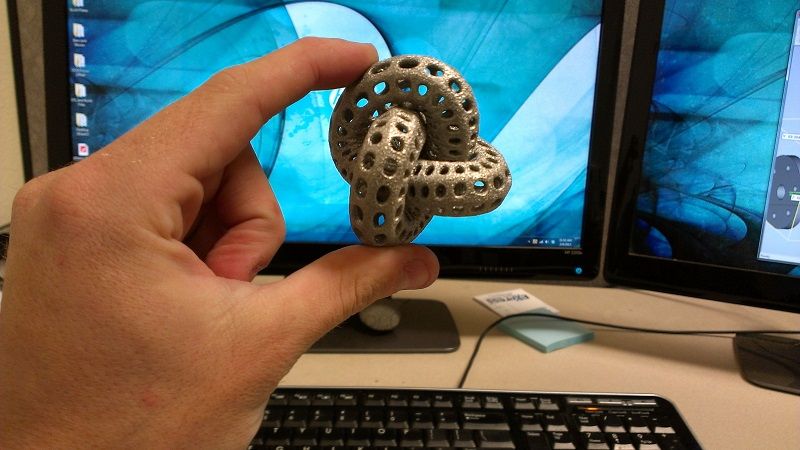

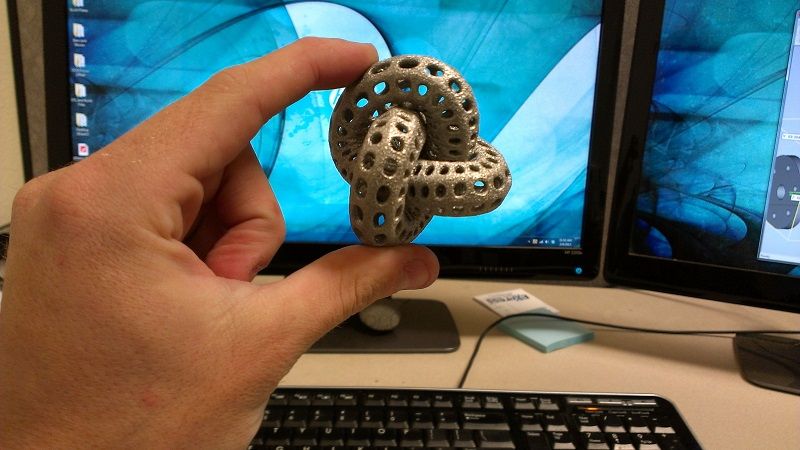

I just wanted to share a couple images of some parts I made at work. My company builds parts primarily out of 6Al-4V Titanium for the Aerospace industry and many other large entities using additive manufacturing. Additive manufacturing for those of you who are not familiar is more commonly referred to as 3D printing.

We take a CAD file (3D image) and slice it into many horizontal layers which we then upload to the machine. In a nutshell, a chamber under vacuum utilizes an electron beam to melt one layer of titanium powder (~50 microns) at a time. From the machine the parts go to a "grit blaster" style cabinet to recycle the unsintered powder and reveal the parts inside.

How sick would a 3D printed Aerospace grade Titanium Host be?! lol. Surely some of you know 3ds max or maya.. somebody send me a file!

*Note there is an identical ball inside of the large ball.

I just wanted to share a couple images of some parts I made at work. My company builds parts primarily out of 6Al-4V Titanium for the Aerospace industry and many other large entities using additive manufacturing. Additive manufacturing for those of you who are not familiar is more commonly referred to as 3D printing.

We take a CAD file (3D image) and slice it into many horizontal layers which we then upload to the machine. In a nutshell, a chamber under vacuum utilizes an electron beam to melt one layer of titanium powder (~50 microns) at a time. From the machine the parts go to a "grit blaster" style cabinet to recycle the unsintered powder and reveal the parts inside.

How sick would a 3D printed Aerospace grade Titanium Host be?! lol. Surely some of you know 3ds max or maya.. somebody send me a file!

*Note there is an identical ball inside of the large ball.