Freitsu

0

- Joined

- Feb 26, 2010

- Messages

- 50

- Points

- 0

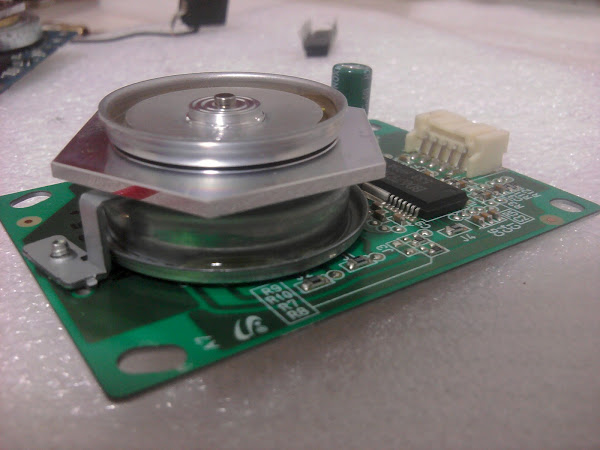

Is anybody here able to decrypt this pinout schematics: Service manual Epson AcuLaser C1100 | RefillBROS

All I can figure out is if I connect +12v (it really says that you should connect +24V but I don't dare yet...) to "INTERLOCK assembly" and then ground it.

Results that I'm getting is if I'm connecting "SCANNER MOTOR ON (L)+5VDC" to just that 5 VDC I get nothing,

but if I on the other hand connect it to ground whole mirror assembly will jump start and then STOP in like a millisecond.

I've tried to touch "SCANNER MOTOR CLOCK" pin to both negative and positive without any results while having connected Scanner motor on...

Any suggestions? I'm really confused about this assembly...

All I can figure out is if I connect +12v (it really says that you should connect +24V but I don't dare yet...) to "INTERLOCK assembly" and then ground it.

Results that I'm getting is if I'm connecting "SCANNER MOTOR ON (L)+5VDC" to just that 5 VDC I get nothing,

but if I on the other hand connect it to ground whole mirror assembly will jump start and then STOP in like a millisecond.

I've tried to touch "SCANNER MOTOR CLOCK" pin to both negative and positive without any results while having connected Scanner motor on...

Any suggestions? I'm really confused about this assembly...