HIMNL9

0

- Joined

- May 26, 2009

- Messages

- 5,318

- Points

- 0

Hi, i got recently some o-like green modules, for a work, and a pair of them (but NOT all) have a strange problem

One of the 10mW, and one of the 30mW, when powered, works good for approximatively 40 to 60 seconds, then the "shape" (don't know how to explain it better) of the dot change for a second, maximum two, then the dot change again and the power decrease to 1/4 or less, and remain so.

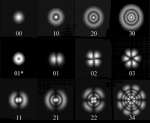

i have no way for get pics, cause at the dot my cam get saturated ..... done a draw for try to give an idea ..... the first shape, the dark green is the usual center beam, and the light green is the usual halo, all is approx, 3 mm diameter, at 2 meters of distance ..... the second shape, the center of the dot increase the luminosity, almost double, and the out ring decrease a bit ..... the third shape, all the spot faint down to 3 / 4 mW, with the center that look a little bit as an unfocused diode (but it's impossible, being a DPSS module), and the total light is the same of the halo, very low.

( the powers measured from the 10 mW one, the 30 mW one have the same proportions, with 35 mW of maximum out, and 8 / 9 mW when dimmed ..... and before someone ask, NO, I HAVE NOT POT MODDED THEM )

)

if i turn it off, wait a pair of seconds, then turn it on again, the modules do a flash of a second at the right intensity, then do the same thing ..... again and again.

if i left it cool for a minute or so, the module restart to work for other 40 / 60 seconds, then do again the problem.

i thought the temperature can be the guilty, so made some measures ..... the module itself pass from 28 C (ambient temperature) to 35 C, before that the problem starts, but when i left it cool, also if the module temperature go down to 29 / 30 C, need to wait the same at least 1 minute, for get it work again correctly.

For the opposite, the driver module, and specifically the driving transistor, go very hot ( 58 C ) in 5 / 6 seconds, then stay at this temperature for the rest of the working cycle (that imho is a bit too much), and the IC part, instead, gradually rise from 28 to 40 C in 30 / 35 seconds, then stay at this level, more or less ..... anyway, when i turn it off, the transistor cool to 30 C in 5 or 6 seconds, and the IC in 10 or 12 seconds, so they are not responsible for the working bad of the module (times don't match)

Anyway, i don't have any way for measure the inside temperature of the crystal assembly or the diode itself without dismantle the modules, and i had no time in these days for do that ..... maybe in the next days i try and check also this, but not now.

anyone had the same problems, or have any idea about why it happens ?

mode hopping ? (in a 10 mW unit ? ..... ..... other than this, the beam don't shift nor disalign, it remain centered and aligned, also when it faint :thinking

..... other than this, the beam don't shift nor disalign, it remain centered and aligned, also when it faint :thinking

defective crystals ? ..... or diodes ? :wtf:

One of the 10mW, and one of the 30mW, when powered, works good for approximatively 40 to 60 seconds, then the "shape" (don't know how to explain it better) of the dot change for a second, maximum two, then the dot change again and the power decrease to 1/4 or less, and remain so.

i have no way for get pics, cause at the dot my cam get saturated ..... done a draw for try to give an idea ..... the first shape, the dark green is the usual center beam, and the light green is the usual halo, all is approx, 3 mm diameter, at 2 meters of distance ..... the second shape, the center of the dot increase the luminosity, almost double, and the out ring decrease a bit ..... the third shape, all the spot faint down to 3 / 4 mW, with the center that look a little bit as an unfocused diode (but it's impossible, being a DPSS module), and the total light is the same of the halo, very low.

( the powers measured from the 10 mW one, the 30 mW one have the same proportions, with 35 mW of maximum out, and 8 / 9 mW when dimmed ..... and before someone ask, NO, I HAVE NOT POT MODDED THEM

if i turn it off, wait a pair of seconds, then turn it on again, the modules do a flash of a second at the right intensity, then do the same thing ..... again and again.

if i left it cool for a minute or so, the module restart to work for other 40 / 60 seconds, then do again the problem.

i thought the temperature can be the guilty, so made some measures ..... the module itself pass from 28 C (ambient temperature) to 35 C, before that the problem starts, but when i left it cool, also if the module temperature go down to 29 / 30 C, need to wait the same at least 1 minute, for get it work again correctly.

For the opposite, the driver module, and specifically the driving transistor, go very hot ( 58 C ) in 5 / 6 seconds, then stay at this temperature for the rest of the working cycle (that imho is a bit too much), and the IC part, instead, gradually rise from 28 to 40 C in 30 / 35 seconds, then stay at this level, more or less ..... anyway, when i turn it off, the transistor cool to 30 C in 5 or 6 seconds, and the IC in 10 or 12 seconds, so they are not responsible for the working bad of the module (times don't match)

Anyway, i don't have any way for measure the inside temperature of the crystal assembly or the diode itself without dismantle the modules, and i had no time in these days for do that ..... maybe in the next days i try and check also this, but not now.

anyone had the same problems, or have any idea about why it happens ?

mode hopping ? (in a 10 mW unit ? .....

defective crystals ? ..... or diodes ? :wtf:

Attachments

Last edited: