IsaacT

0

- Joined

- Aug 25, 2010

- Messages

- 5,950

- Points

- 83

MS-V4 PL520 Build Thread!!!

Birthday: 5/16/2013

Hello everyone, today I am pleased to announce that my newest build, named Loki, has

been completed! This was possibly the most difficult build I have ever attempted, and

I wil cover the reasons for this below. But first, let me give you a run down of the parts used

and what sources I used to obtain the parts used.

Parts List:

1 x MS-V4 Host from Sinner: 35 USD

1 x PL520 Direct Green Diode from DTR: 145 USD

1 x Microboost Driver preset to 300mA from Flaminpyro: 30 USD

Total Build Cost: 210 USD

I also purchased Arctic Alumina Thermal Adhesive but ended up not using it due to some

wire length misestimations(I'll cover that later).

I have been planning this build since mid-March, and have had the diode sitting on my desk

since April 11th. Having finally gotten the host in, I knew it was time to put this wonderful

new piece of technology together.

The Process:

As I mentioned earlier, this was a very difficult build for me for a number of reasons. First, I do not

trust my helping hands to hold anything that weighs anywhere at or above the weight of a

C6 Heatsink...so all of this had to be done very carefully with my two hands. One to hold the

driver and the wire together, and one to apply the Iron. Second, this host is a Press Fit head. This is great for thermal transfer, but

it is exceedingly difficult to get the Copper Module into the hole and pressfit it all the way down.

I was literally pounding my vice with a hammer for over 30 minutes working it down millimeter by

precious millimeter. Third, the space one has to work with in this build are very small.

Ideally the microboost would have been mounted on the diode pins, but as I was unsure of what

I would need to do I ordered the Diode pressfit with leads. The LAST thing I wanted to

do was damage the 150 dollar diode with a slightly too long Iron touch.

First, I began by pressing the copper module into the head. After A LOT of time spent putting

all the force I could into my vice, I finally managed it. Here is a picture of the complete module:

The next step, of course, was to trim the wires and solder the connections of the microboost.

After reading the manuals for the driver AND the diode, and googling what anode and cathode

were(I can't seem to remember which is which EVER), I was certain that I wasn't going to run

into any problems with the setup I was going for.

So here is a picture of the completed module with the microboost soldered on.

NOTE: I trimmed the wires based on my guestimation of what length would keep everything small

while allowing for flexibility. My guestimations were a bit off and the driver doesn't really want to

sit down on the metal plate. For a high current build this could be problematic, but this

build runs so cool I am not worried.

Since I could not get the driver to sit down, I resorted to wrapping some electrical tape around

the assembly to make sure there were no shorts(a problem I have had with one or two builds in

the past - grrr). This worked well enough at first, but electrical tape just doesn't stick as well

as I would like and it allowed the driver to get caught on threads when removing the head

to work on it. For this reason I later changed to regular old scotch tape. Keeps the bits separate,

but sticks a whole lot better.

And with tape instead of electrical tape:

Last real step was to thread the little head module in and see if it worked. There a couple initial issues,

not the least of which was that none of my batteries had charge. Other problems were that

the contact point wasn't getting contact with the battery so I added a little one coil length of spring

to simply take up some more space and grab that contact point.

Completed Build Pictures:

Okay, everybody wants eye candy so I will give you some! I will start with pictures of the host

and then move on to pictures of the completed laser in action and then some comparative shots

between it and my 532nm laser. It is noteworthy that this is NOT the focus adapter that came

with the host. Sinner sent a conical focus adapter with the host that is nice(once you manage to pressfit the aixiz ring into it)

but I did not feel it fit the personality of this build, so I have utilized a thin circle type focus adapter

and I think it works splendidly with the host.

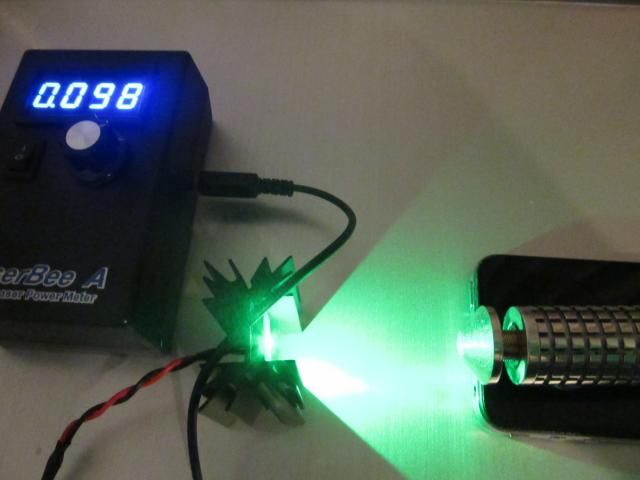

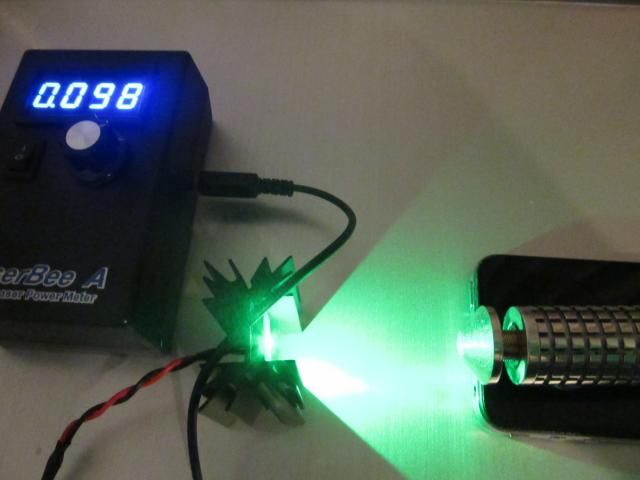

But How Powerful Is It?

Answer being: Not very. Below are two LPM pictures. The first one is with 3 Element Glass Lens

and the second is with a G2 LFL Lens. I do much prefer the 3 Element on this build, and to be specific

I am referring to the 445nm 3 Element Glass. The 650nm 3 Element Glass does well but I see

about 5mW loss in comparison to the 445nm coated lens. Peaks were 80mW and 104mW for 445nm

3-Ele and G2 LFL respectively.

Thank You for Reading!

I want to thank everyone who took the time to read this build thread. I really enjoyed building my

first direct green diode, and it rocks the socks off of DPSS green lasers in terms of color in my opinion.

I am now the proud owner of EIGHT different wavelengths, and I am loving it! I am about to snap

a pic of all my different wavelengths side by side, and I will post it when I get it taken.

Thanks,

Isaac

Birthday: 5/16/2013

Hello everyone, today I am pleased to announce that my newest build, named Loki, has

been completed! This was possibly the most difficult build I have ever attempted, and

I wil cover the reasons for this below. But first, let me give you a run down of the parts used

and what sources I used to obtain the parts used.

Parts List:

1 x MS-V4 Host from Sinner: 35 USD

1 x PL520 Direct Green Diode from DTR: 145 USD

1 x Microboost Driver preset to 300mA from Flaminpyro: 30 USD

Total Build Cost: 210 USD

I also purchased Arctic Alumina Thermal Adhesive but ended up not using it due to some

wire length misestimations(I'll cover that later).

I have been planning this build since mid-March, and have had the diode sitting on my desk

since April 11th. Having finally gotten the host in, I knew it was time to put this wonderful

new piece of technology together.

The Process:

As I mentioned earlier, this was a very difficult build for me for a number of reasons. First, I do not

trust my helping hands to hold anything that weighs anywhere at or above the weight of a

C6 Heatsink...so all of this had to be done very carefully with my two hands. One to hold the

driver and the wire together, and one to apply the Iron. Second, this host is a Press Fit head. This is great for thermal transfer, but

it is exceedingly difficult to get the Copper Module into the hole and pressfit it all the way down.

I was literally pounding my vice with a hammer for over 30 minutes working it down millimeter by

precious millimeter. Third, the space one has to work with in this build are very small.

Ideally the microboost would have been mounted on the diode pins, but as I was unsure of what

I would need to do I ordered the Diode pressfit with leads. The LAST thing I wanted to

do was damage the 150 dollar diode with a slightly too long Iron touch.

First, I began by pressing the copper module into the head. After A LOT of time spent putting

all the force I could into my vice, I finally managed it. Here is a picture of the complete module:

The next step, of course, was to trim the wires and solder the connections of the microboost.

After reading the manuals for the driver AND the diode, and googling what anode and cathode

were(I can't seem to remember which is which EVER), I was certain that I wasn't going to run

into any problems with the setup I was going for.

So here is a picture of the completed module with the microboost soldered on.

NOTE: I trimmed the wires based on my guestimation of what length would keep everything small

while allowing for flexibility. My guestimations were a bit off and the driver doesn't really want to

sit down on the metal plate. For a high current build this could be problematic, but this

build runs so cool I am not worried.

Since I could not get the driver to sit down, I resorted to wrapping some electrical tape around

the assembly to make sure there were no shorts(a problem I have had with one or two builds in

the past - grrr). This worked well enough at first, but electrical tape just doesn't stick as well

as I would like and it allowed the driver to get caught on threads when removing the head

to work on it. For this reason I later changed to regular old scotch tape. Keeps the bits separate,

but sticks a whole lot better.

And with tape instead of electrical tape:

Last real step was to thread the little head module in and see if it worked. There a couple initial issues,

not the least of which was that none of my batteries had charge. Other problems were that

the contact point wasn't getting contact with the battery so I added a little one coil length of spring

to simply take up some more space and grab that contact point.

Completed Build Pictures:

Okay, everybody wants eye candy so I will give you some! I will start with pictures of the host

and then move on to pictures of the completed laser in action and then some comparative shots

between it and my 532nm laser. It is noteworthy that this is NOT the focus adapter that came

with the host. Sinner sent a conical focus adapter with the host that is nice(once you manage to pressfit the aixiz ring into it)

but I did not feel it fit the personality of this build, so I have utilized a thin circle type focus adapter

and I think it works splendidly with the host.

But How Powerful Is It?

Answer being: Not very. Below are two LPM pictures. The first one is with 3 Element Glass Lens

and the second is with a G2 LFL Lens. I do much prefer the 3 Element on this build, and to be specific

I am referring to the 445nm 3 Element Glass. The 650nm 3 Element Glass does well but I see

about 5mW loss in comparison to the 445nm coated lens. Peaks were 80mW and 104mW for 445nm

3-Ele and G2 LFL respectively.

Thank You for Reading!

I want to thank everyone who took the time to read this build thread. I really enjoyed building my

first direct green diode, and it rocks the socks off of DPSS green lasers in terms of color in my opinion.

I am now the proud owner of EIGHT different wavelengths, and I am loving it! I am about to snap

a pic of all my different wavelengths side by side, and I will post it when I get it taken.

Thanks,

Isaac

Last edited: