- Joined

- Dec 9, 2010

- Messages

- 63

- Points

- 0

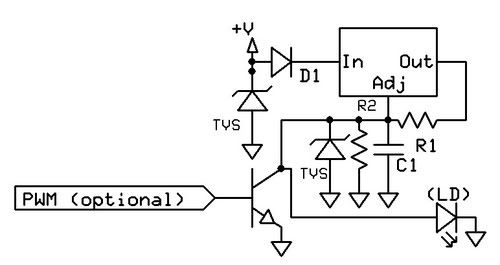

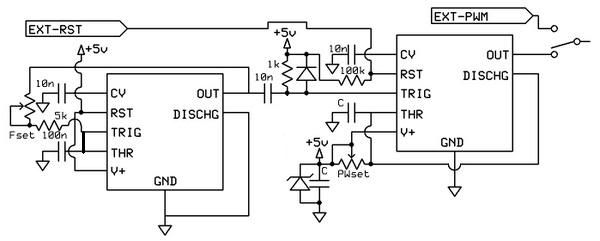

I was just browsing around and happened to stumble upon some 1.25A - 1.5A 445s on here and noticed a bunch of people debating what to use for drivers. Some were saying why not use a LM338 or LM317 instead of, for example, a FlexmodP3.... the argument was mainly that the driver had other safety features in it that were helpful.

What other safety features are we talking about here because 40 bucks and a lot of controls that arent typically used on handhelds such as balance and (i forget the other adjustable feature). I know it has some sort of ESD feature, but this is my point: I've heard that the LMXXX series regulators have a built in shut off if they over heat, so that is in some form a safety feature in regards to the LD right?

Not only that but the constant current from a LM317 or LM338 is 1.25A when using a 1 ohm resistor. Does that mean that a small DDL board with this setup would be safe for a decent powered handheld??? Or is there just something extra special about these drivers that I'm missing?

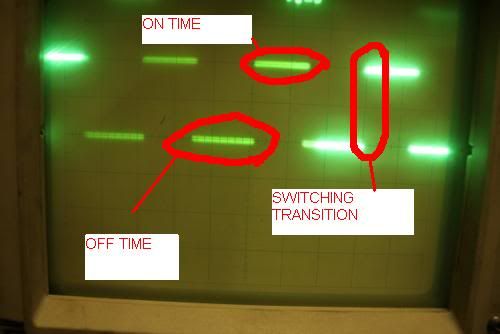

(no idea what capacitor(s) would be idea bc I still dont understand the function)

What other safety features are we talking about here because 40 bucks and a lot of controls that arent typically used on handhelds such as balance and (i forget the other adjustable feature). I know it has some sort of ESD feature, but this is my point: I've heard that the LMXXX series regulators have a built in shut off if they over heat, so that is in some form a safety feature in regards to the LD right?

Not only that but the constant current from a LM317 or LM338 is 1.25A when using a 1 ohm resistor. Does that mean that a small DDL board with this setup would be safe for a decent powered handheld??? Or is there just something extra special about these drivers that I'm missing?

(no idea what capacitor(s) would be idea bc I still dont understand the function)