- Joined

- Feb 18, 2012

- Messages

- 796

- Points

- 28

Hey guys,

We all know how hot linear drivers can get sometimes, especially when ran at such a high current as 1.8A. Today I'll be showing you how I heatsink these hot linears :eg:

So let's cut to the chase.

Here is a customer's build I finished yesterday:

Walk with me as I prep the driver...

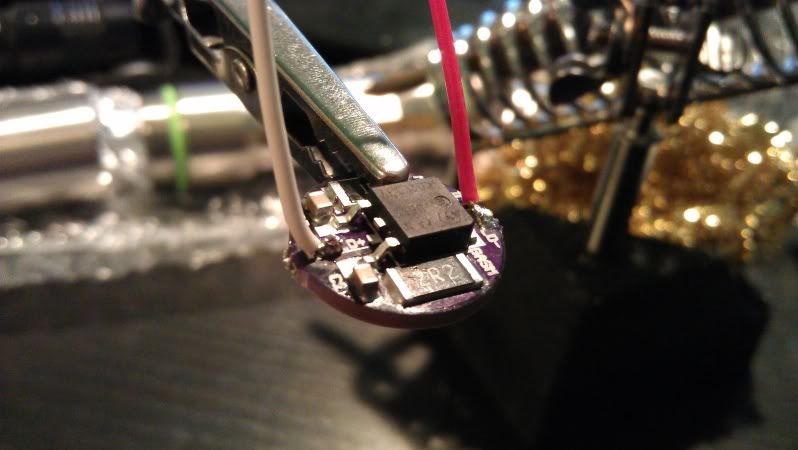

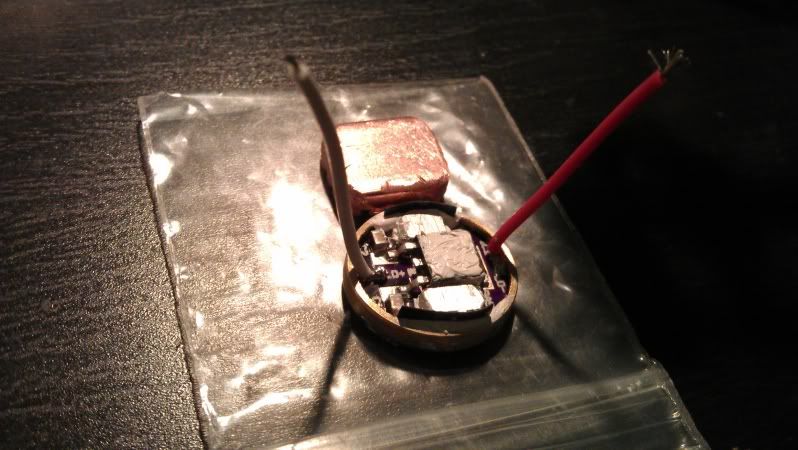

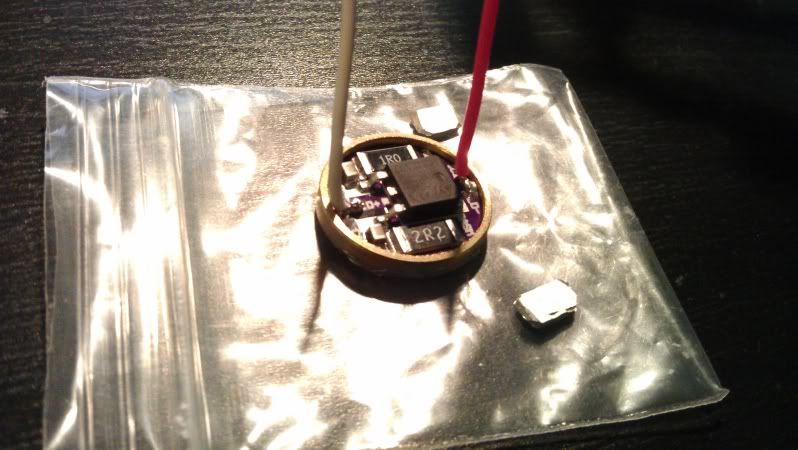

Solder the leads on:

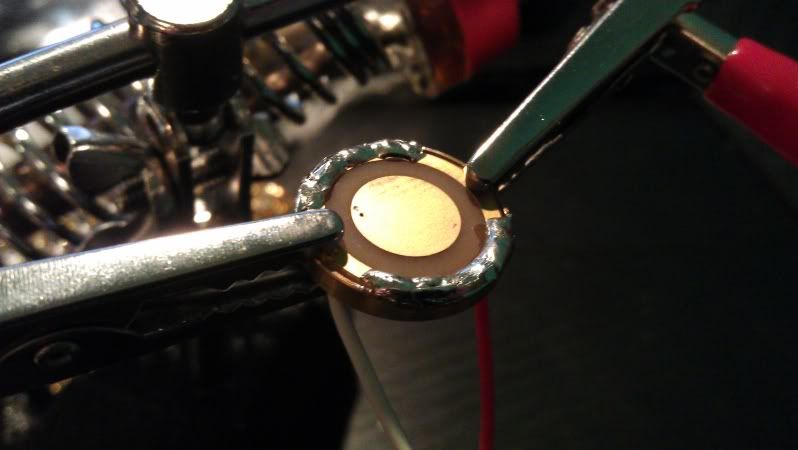

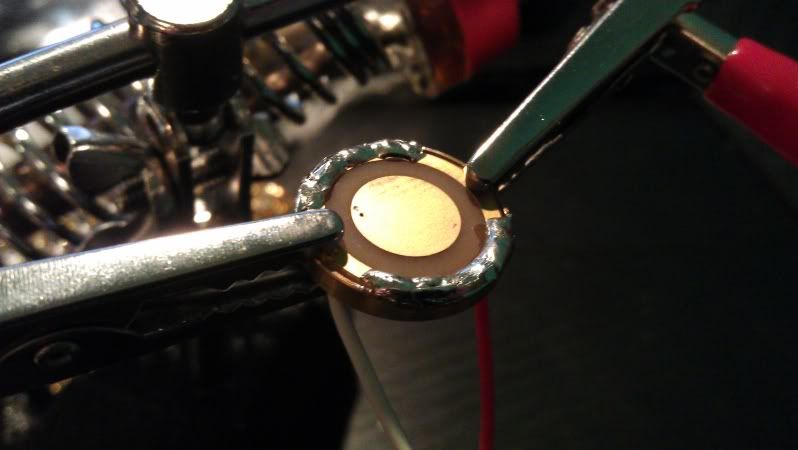

Solder the brass retaining ring to the driver for a good negative ground:

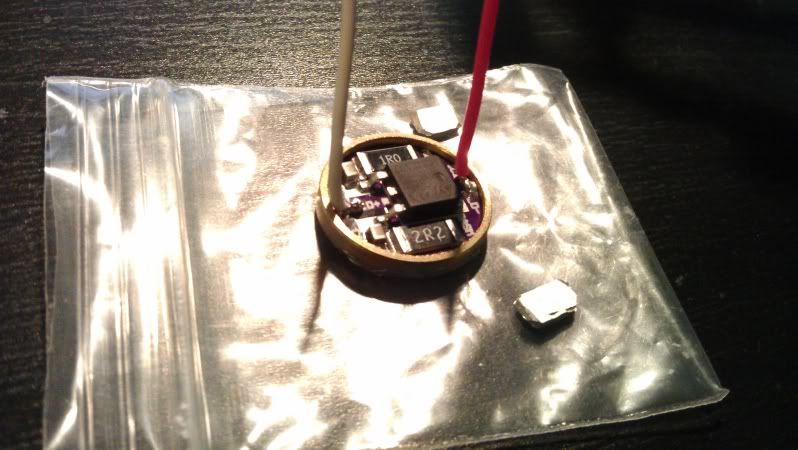

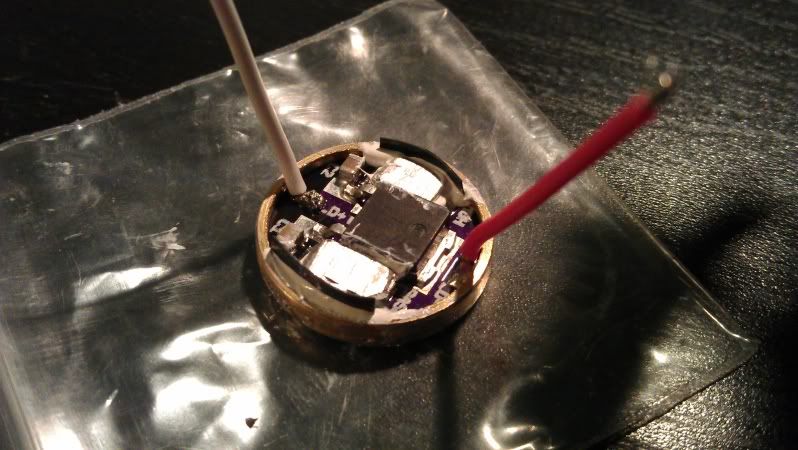

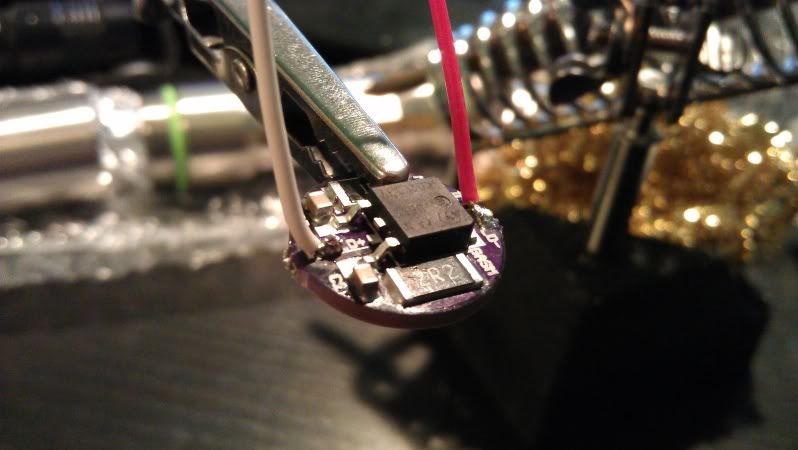

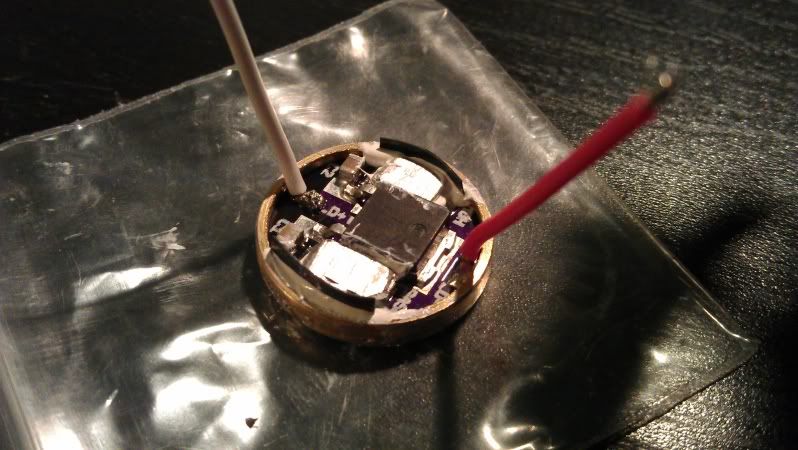

Heatsink the resistors with aluminum fins using non-conductive, non-capacitative Arctic Silver Ceramique 2 thermal compound, then electrically isolate "high-risk" zones with electrical tape for extra precaution against short circuit:

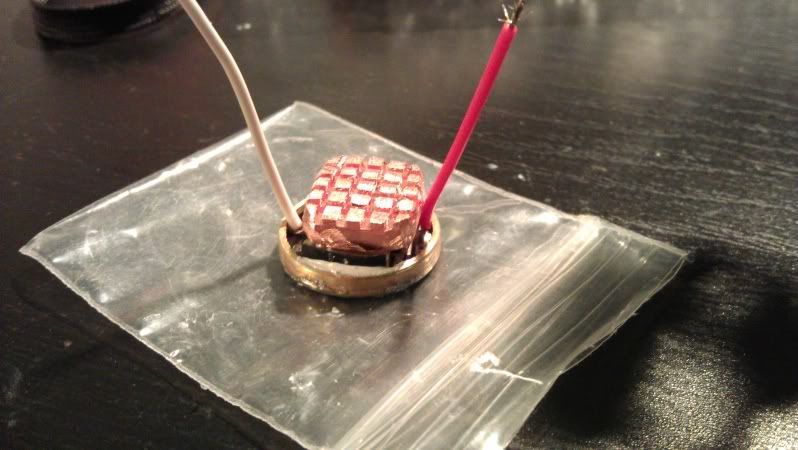

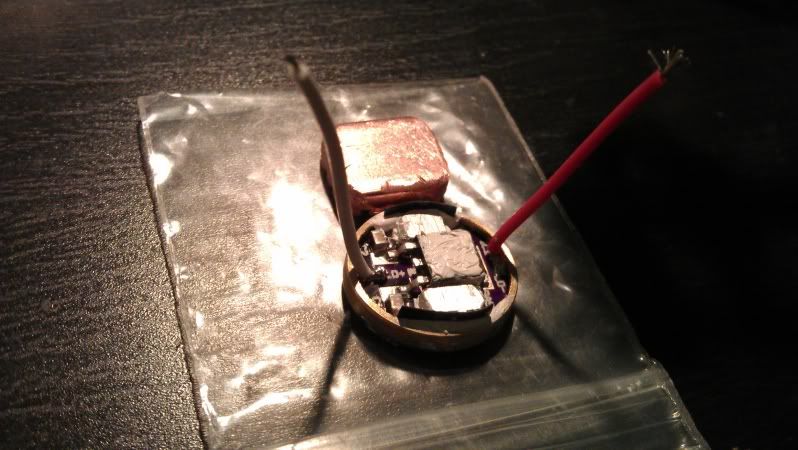

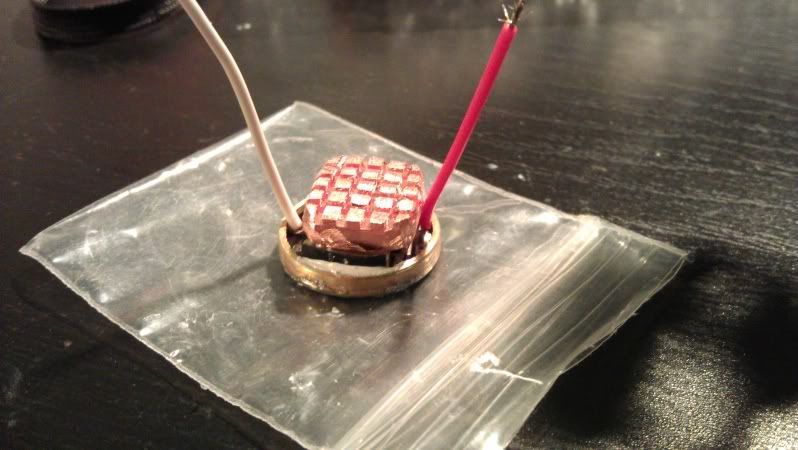

Prepped the IC for mounting a finned copper heatsink, which needs to be ground down in the corners and height to fit in the pill:

Then prep the underside of the pill & corners of the copper heatsink with thermal compound as the heatsink will press against the pill:

Everything else is fitted together, spread thermal compound along the module then slide it in the heatsink

For maximum heatsinking effect: prep the underside of the large copper heatsink with thermal compound as it will press against the top of the pill when installed.

Then enjoy the beam..

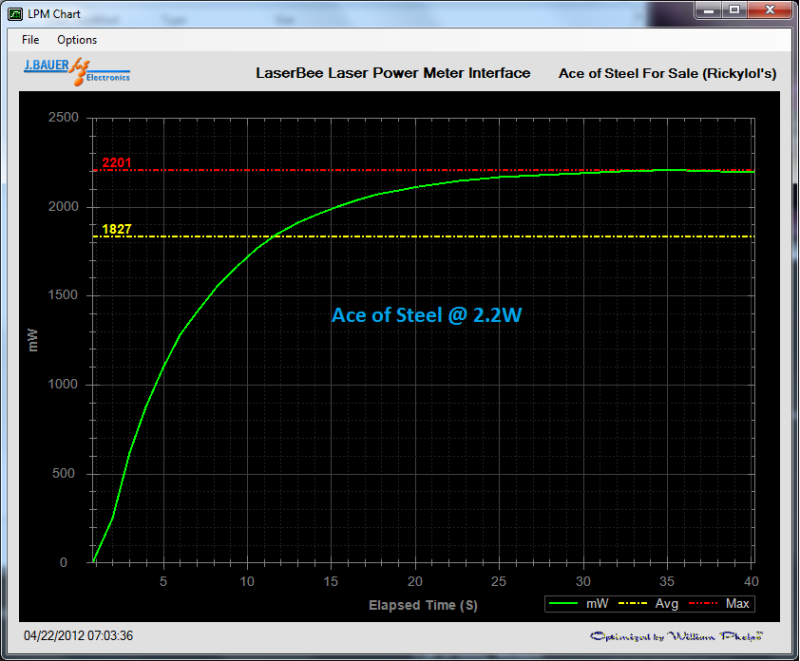

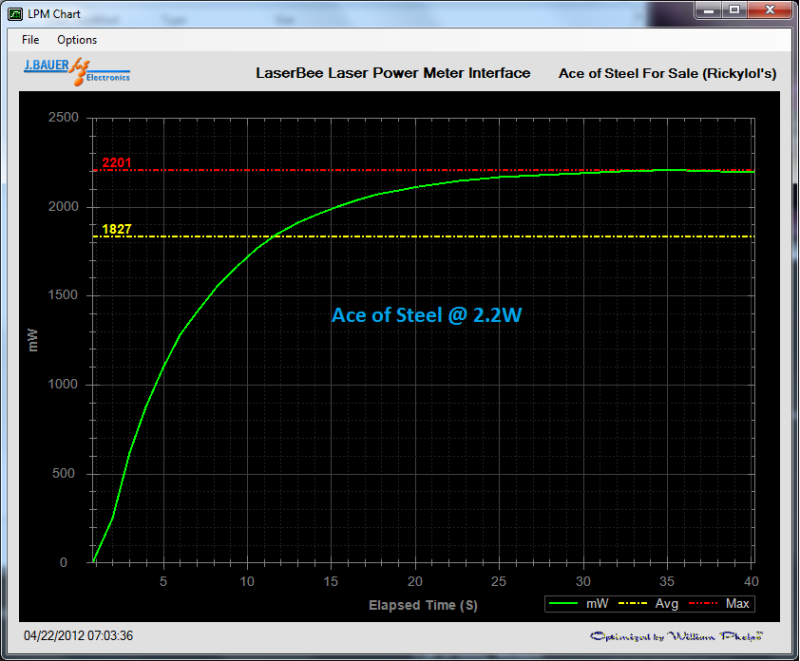

& results.

I was able to run this laser for over 3 minutes w/o thermal protection kicking in and the host just beginning to get uncomfortably warm. I could probably run it longer but I didn't want to go any further.

Hope this helps anyone deal with these hot linears better :beer:

Ryan

We all know how hot linear drivers can get sometimes, especially when ran at such a high current as 1.8A. Today I'll be showing you how I heatsink these hot linears :eg:

So let's cut to the chase.

Here is a customer's build I finished yesterday:

Walk with me as I prep the driver...

Solder the leads on:

Solder the brass retaining ring to the driver for a good negative ground:

Heatsink the resistors with aluminum fins using non-conductive, non-capacitative Arctic Silver Ceramique 2 thermal compound, then electrically isolate "high-risk" zones with electrical tape for extra precaution against short circuit:

Prepped the IC for mounting a finned copper heatsink, which needs to be ground down in the corners and height to fit in the pill:

Then prep the underside of the pill & corners of the copper heatsink with thermal compound as the heatsink will press against the pill:

Everything else is fitted together, spread thermal compound along the module then slide it in the heatsink

For maximum heatsinking effect: prep the underside of the large copper heatsink with thermal compound as it will press against the top of the pill when installed.

Then enjoy the beam..

& results.

I was able to run this laser for over 3 minutes w/o thermal protection kicking in and the host just beginning to get uncomfortably warm. I could probably run it longer but I didn't want to go any further.

Hope this helps anyone deal with these hot linears better :beer:

Ryan

Last edited: