Hi everybody!

This is my first post here.

For start I wanna to apologize for my english! I'm not a native, but I'll try to explain in minimum details what I want.

I even know for where I begin... :undecided:

Well, I've read a lot of stuff on internet and here on the forum...but it seems as more I read more I get confused.

So, I'll say what I need.

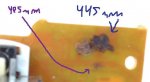

I'm looking for a laser diode that could burn/write/engrave a PCI surface! Just the surface, and isn't made of copper! It's like this on the picture:

PrintedCircuitBoardImagem

I guess the surface of this kind of board is made by varnish ink, so that laser have to be powerful enough to burn the "skin" the board.

My goal is not to draw a circuit on the board! Is just write words and numbers on it.

I hope you have understood!

I read around, that the low wavelength is better for making/burn in non black materials, then the wavelenght have to be lower for my purpose, right?

I would like that you guys could indicate the best diode laser, lens and drivers, In order to I possibly can do what I want

I'm sorry for ask all for you, but I'm a tired to looking for and don't find what I need even more because I'm in a hurry! :cryyy:

Thanks in advance for who help me!:thanks:

This is my first post here.

For start I wanna to apologize for my english! I'm not a native, but I'll try to explain in minimum details what I want.

I even know for where I begin... :undecided:

Well, I've read a lot of stuff on internet and here on the forum...but it seems as more I read more I get confused.

So, I'll say what I need.

I'm looking for a laser diode that could burn/write/engrave a PCI surface! Just the surface, and isn't made of copper! It's like this on the picture:

PrintedCircuitBoardImagem

I guess the surface of this kind of board is made by varnish ink, so that laser have to be powerful enough to burn the "skin" the board.

My goal is not to draw a circuit on the board! Is just write words and numbers on it.

I hope you have understood!

I read around, that the low wavelength is better for making/burn in non black materials, then the wavelenght have to be lower for my purpose, right?

I would like that you guys could indicate the best diode laser, lens and drivers, In order to I possibly can do what I want

I'm sorry for ask all for you, but I'm a tired to looking for and don't find what I need even more because I'm in a hurry! :cryyy:

Thanks in advance for who help me!:thanks: