- Joined

- Nov 2, 2012

- Messages

- 626

- Points

- 43

My 650nm laser diode and driver arrived in the mail today, barely two days after leaving DTR's laser shop. I highly recommend doing business with DTR, due to his friendly and approachable attitude, and his willingness to go an extra mile or three to help you out and get you closer to your goal, which is building your own lasers. The same can be said about Survival Lasers; it's their C6 hosts I'm using, and dealing with them has always been a positive experience as well.

It's been months since my Lazerer LZCS-650 turned LED on me, so it's nice to have a single-mode 650nm laser once again. I'm not going to show the whole build in this thread but I took some pictures to show how I've been doing things. It turns out the lab stand is good for more than just setting up photo displays.

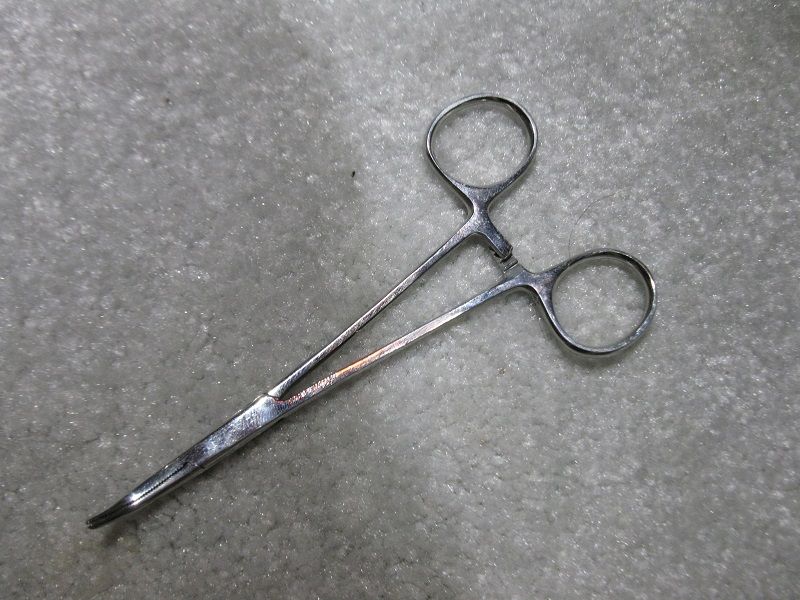

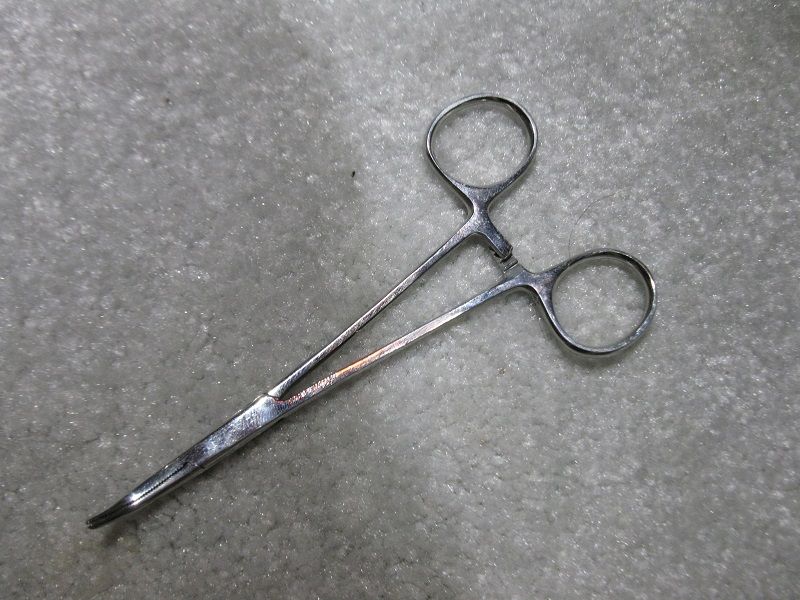

That's what I use to build a C6, more or less. The lab stand keeps the soldering iron safely out of the way, which would otherwise be a big problem. It's not quite ideal for holding the laser parts, but it's good enough. Channel locks and pliers to remove the back end (silver part) of the module, since it's on pretty tight. The channel locks are good for tightening down the pill as well. The latching tongs are good for holding hot stuff, or PITA stuff in tight spaces.

There are the latching tongs. I remembered that I had them and they made several steps in the process a lot easier. I think they would be a useful addition to any builder's toolkit.

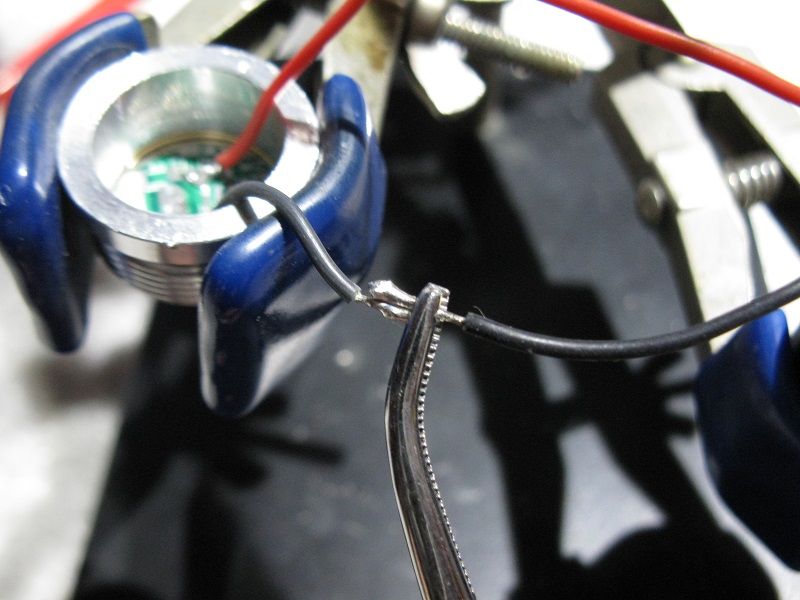

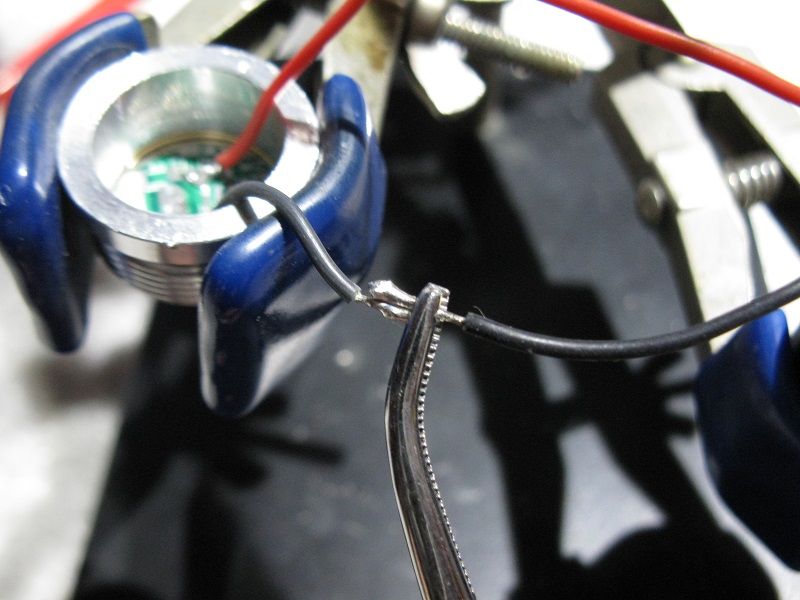

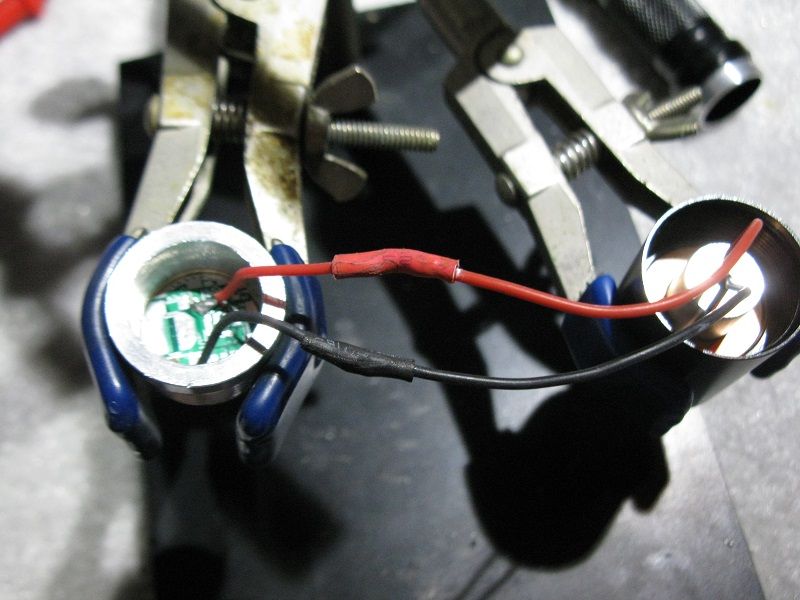

Soldering the wires is the most tedious part of putting together a C6. Maybe I'm doing something wrong, but the tinned ends are stiff and short, making them difficult to twist together for soldering. With the latching tongs you can forget that. Set up the joint as needed and latch up, the tongs are strong enough to hold it in place and they won't be bothered by the heat of soldering.

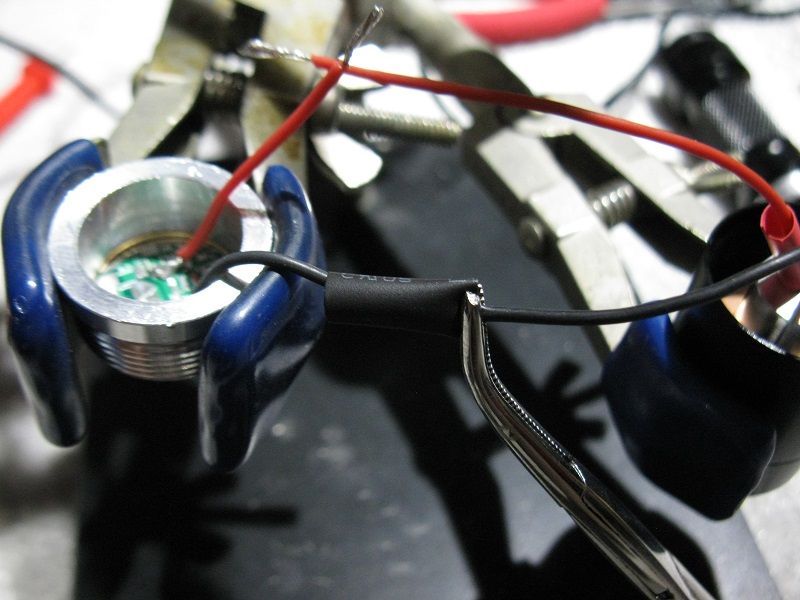

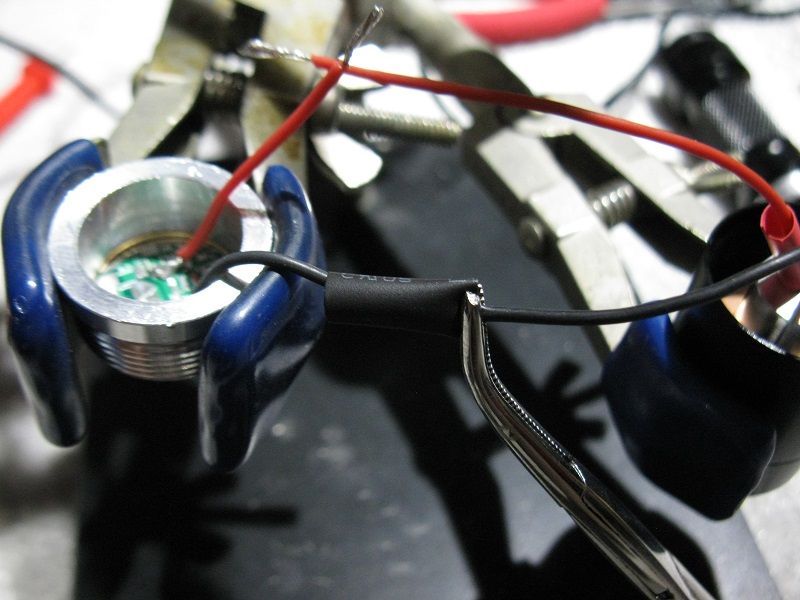

I find that shrink wrap (heat shrink?) can be irritating as well. It's prone to not staying in place when you go to shrink it down, but clearly, it's no match for the tongs. I'm not holding them by hand; once latched up the tongs will maintain a strong grip without any further effort on my part. Now I can shrink it down and the shrink wrap will stay right where I need it.

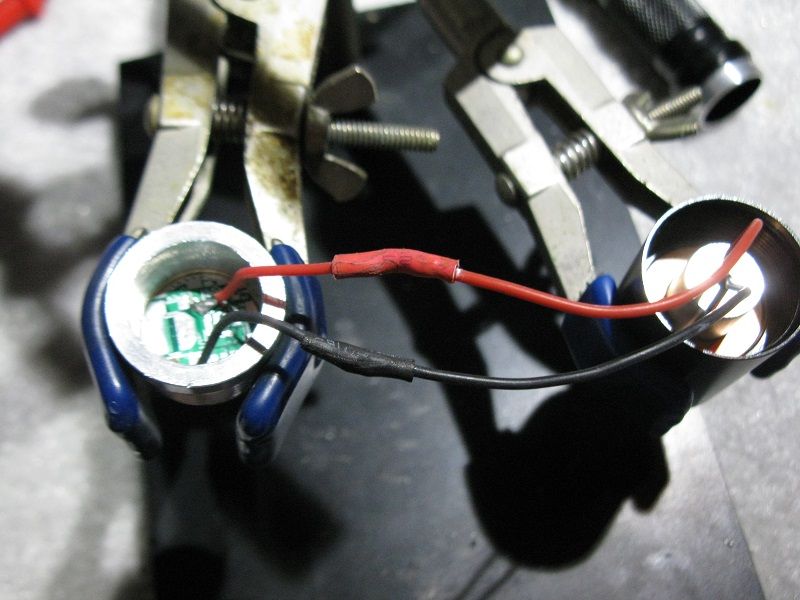

It ended up looking like that, and I tested the laser and it worked.

Unfortunately what you see there ended up not working and I had to change things. For one thing, the wires were too long and I had to shorten them. But the real bastard child was the back end of the laser module, the silver part. I've seen a few posts that say you don't need to remove the silver part, but I guess it depends on the host. I removed the back part in my other builds but tried to leave it in place this time. The heatsink just wouldn't fit right with that part on there, even after I shortened the wires, so I removed it. After that, the heatsink fit into place without any trouble.

Anyhow, that's how I addressed certain issues that kept coming up again and again. It would be interesting to see what others have come up with to solve recurrent problems. Have fun!

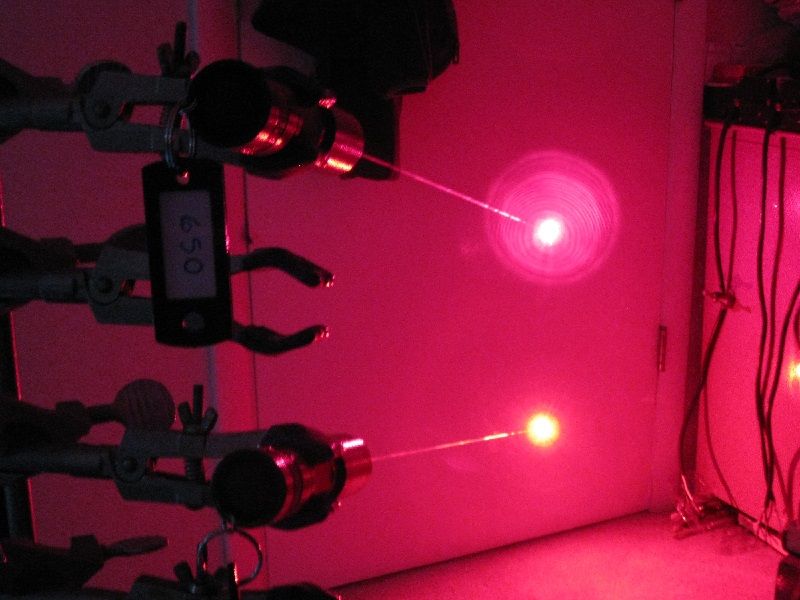

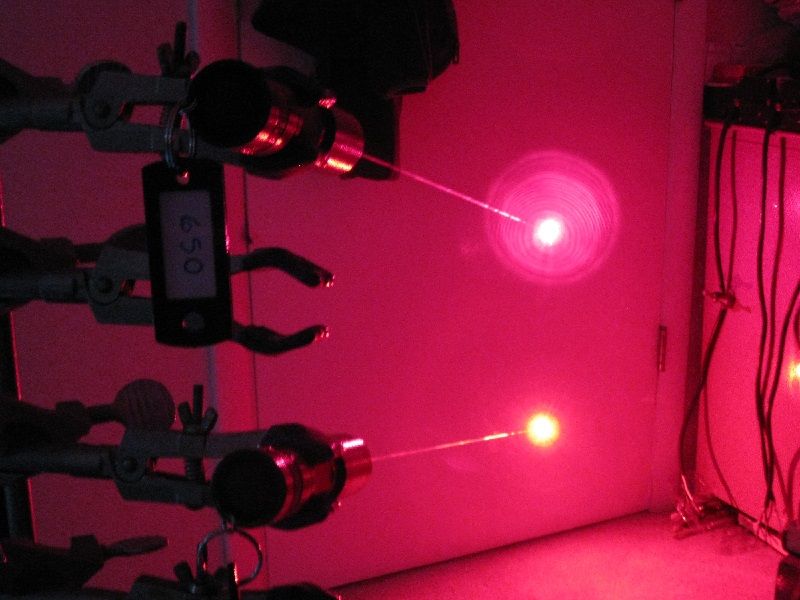

ETA: This 650nm (top) versus 638nm (bottom), very nice to have two single mode red wavelengths again

It's been months since my Lazerer LZCS-650 turned LED on me, so it's nice to have a single-mode 650nm laser once again. I'm not going to show the whole build in this thread but I took some pictures to show how I've been doing things. It turns out the lab stand is good for more than just setting up photo displays.

That's what I use to build a C6, more or less. The lab stand keeps the soldering iron safely out of the way, which would otherwise be a big problem. It's not quite ideal for holding the laser parts, but it's good enough. Channel locks and pliers to remove the back end (silver part) of the module, since it's on pretty tight. The channel locks are good for tightening down the pill as well. The latching tongs are good for holding hot stuff, or PITA stuff in tight spaces.

There are the latching tongs. I remembered that I had them and they made several steps in the process a lot easier. I think they would be a useful addition to any builder's toolkit.

Soldering the wires is the most tedious part of putting together a C6. Maybe I'm doing something wrong, but the tinned ends are stiff and short, making them difficult to twist together for soldering. With the latching tongs you can forget that. Set up the joint as needed and latch up, the tongs are strong enough to hold it in place and they won't be bothered by the heat of soldering.

I find that shrink wrap (heat shrink?) can be irritating as well. It's prone to not staying in place when you go to shrink it down, but clearly, it's no match for the tongs. I'm not holding them by hand; once latched up the tongs will maintain a strong grip without any further effort on my part. Now I can shrink it down and the shrink wrap will stay right where I need it.

It ended up looking like that, and I tested the laser and it worked.

Unfortunately what you see there ended up not working and I had to change things. For one thing, the wires were too long and I had to shorten them. But the real bastard child was the back end of the laser module, the silver part. I've seen a few posts that say you don't need to remove the silver part, but I guess it depends on the host. I removed the back part in my other builds but tried to leave it in place this time. The heatsink just wouldn't fit right with that part on there, even after I shortened the wires, so I removed it. After that, the heatsink fit into place without any trouble.

Anyhow, that's how I addressed certain issues that kept coming up again and again. It would be interesting to see what others have come up with to solve recurrent problems. Have fun!

ETA: This 650nm (top) versus 638nm (bottom), very nice to have two single mode red wavelengths again

Last edited: