- Joined

- May 26, 2013

- Messages

- 17

- Points

- 0

Hello all. This is my first post, so let me first introduce myself (feel free to skip to another paragraph if you don't care). I'm an industrial Designer with a mechanical mind and an interest in lasers. I feel that with the right tools and the right knowledge, you can do anything. I'm currently out of stable work, so I've been working on some projects (as cheaply as possible) to broaden my capabilities and services, as well as having fun while doing it. I recently built a RepRap based 3D Printer, and since I've been craving another large project. I'm giving myself a goal of around a year from now or so to at least get started on a large laser cutter, probably about a 40W+ CO2, but I need some more income for something like that. After seeing some cheaper, lower power diode based laser cutters, I've decided to start with that. Which leads me to my planned build...

[The Build]

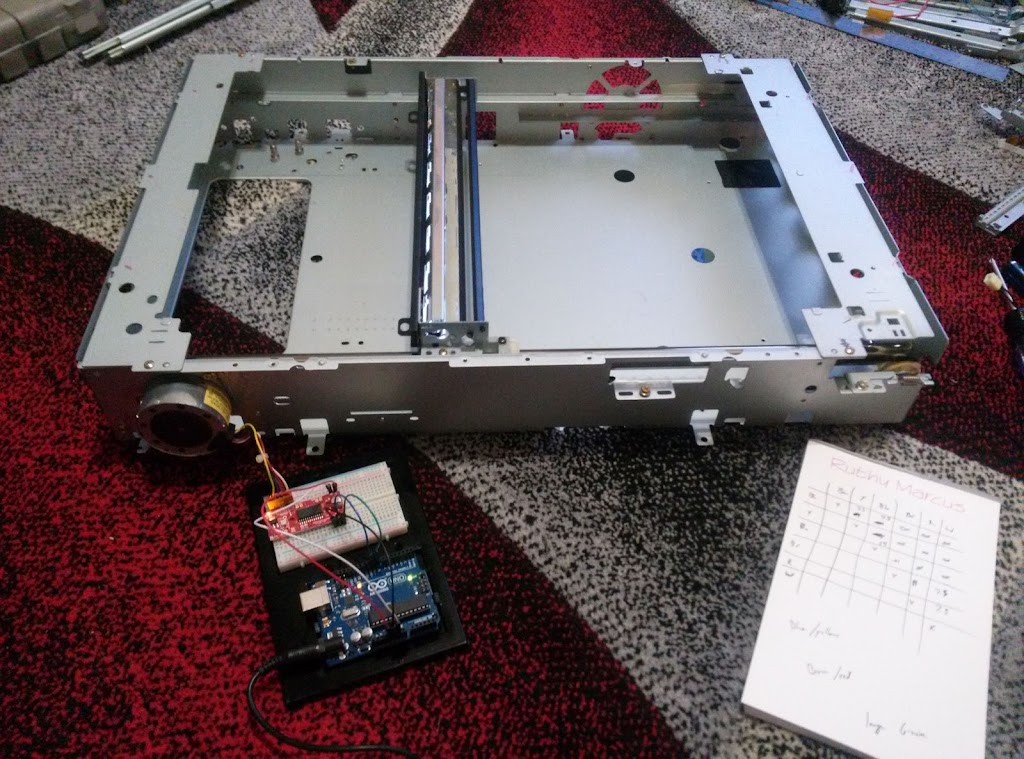

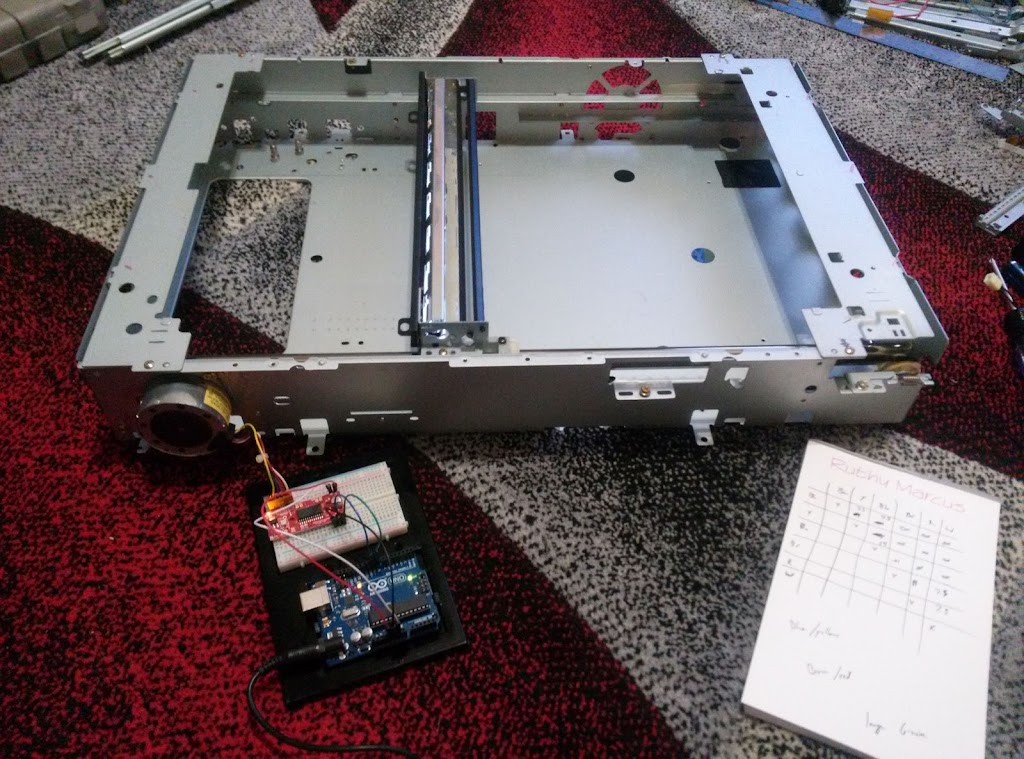

I've decided to use scrap electronics and make a low cost laser cutter out of it. After asking friends and family for donations, I've torn apart 2 printers, 3 scanners, and a tabletop copy machine. As a result, I have a smattering of motors (DC and stepper), linear shafts, bearings, gears, belts, screws, etc. I left some parts connected to the frames they came on if I thought it would be beneficial to do so, but just pulled apart other stuff and sorted it.

After identifying the parts and assemblies I want to use as the main base of it, I stripped off everything I didn't need. I also had to swap out some of the steppers for bipolar steppers. I ended up deciding on using the main, large scanner assembly from the top of the copy machine for the primary movement (what will end up the Y movement). Of the tabletop scanners, only one used a linear shaft (others used molded plastic and pushed against the glass for support), so I'll be using that one for the secondary movement (X movement), with the extra stability from another linear shaft pulled from something else. I've started teaching myself to code Arduino, and by connecting an Arduino Uno to a pair of EasyStepper controllers, I was able to get the steppers to move individually (based on a standalone program, but being sent commands from the computer quite yet.

I plan on using the copy machine scanner as the base of it all. I'll be putting drawer slides (harvested from the copy machine) on either side to move along with the movement. I plan on cutting apart the smaller scanner so it consists of only the motor movement, belt, and linear shafts, as well as make the carriage smaller. This will all link up with the copy machine movement and rest on the drawer slides. There will be a big piece of flat metal (or something else? MDF?) as the print surface, located above the copy machine movement, but below the smaller scanner movement (about inline with the drawer slides). This will give me a rough cutting area of about 16"x12".

[The Laser Question]

This is pretty much as far as I've gotten in terms of general planning. The next big question, which I come to you for, is the laser itself. I should mention here that I have some experience with lasers. Not a ton, but I know enough to err on the side of caution. I've made laser pointers with a red DVD burner diode and a mag light housing, and I have a Wicked Arctic 1W laser (I know, I know). I've seen people make engravers with DVD lasers, but it can't cut through much and is really slow. I plan on going with a blue diode, unless someone here can convince me otherwise. Oh, and I also plan on building something into this where it will shade the beam while it's cutting so I won't need to use glasses all the time while it's cutting, but I still will use glasses whenever I'm operating it. I've been doing some research into blue diodes, cooling them, powering them, etc. I know the capabilities of something like this is limited, but I'd hopefully like to engrave plastic, maybe cut thin plastic, cut foam, paper, card stock, and cardboard, etc. I would also hope it could move at a decent speed and not take a half hour to do a small job. Does anyone here have much experience with cutting with blue diodes? I'm thinking something between a 1-3W laser. Is going from 1 up to 3 in this case worth it? Should I get a driver with it or assemble it myself, and would it be beneficial to pulse the beam? Any input, suggestions, or links (for purchase or simply as research) would help a lot.

I should mention that I wouldn't mind doing a small build for a battery powered pointer before making a wired in, higher powered version. Possibly a smaller .5-1W pointer I could build into a small host. I'd also like to get some better glasses to use with the laser cutter, especially since I know the WL glasses are crap (which is one of the reasons I hardly ever use the Arctic indoors), so some direction on this would be go too.

Another small question (if you guys would know) is should I add any kind of Z movement? I have a couple small rack and pinion movements connected to a tiny stepper, so I could get about 3" of Z movement if I wanted. Would this extra effort benefit me at all, or should I just forget about it? How much would I be changing the height of the laser or adjusting the focus?

I'm hoping this will be a good laser project, while trying to keep this project as inexpensive as possible. I know the laser is going to be the main cost in this, but since I've only spent about $40 on parts so far (for the Arduino and EasySteppers), hopefully I can keep the whole project under around $250.

Any and all advice would be greatly appreciated!

[The Build]

I've decided to use scrap electronics and make a low cost laser cutter out of it. After asking friends and family for donations, I've torn apart 2 printers, 3 scanners, and a tabletop copy machine. As a result, I have a smattering of motors (DC and stepper), linear shafts, bearings, gears, belts, screws, etc. I left some parts connected to the frames they came on if I thought it would be beneficial to do so, but just pulled apart other stuff and sorted it.

After identifying the parts and assemblies I want to use as the main base of it, I stripped off everything I didn't need. I also had to swap out some of the steppers for bipolar steppers. I ended up deciding on using the main, large scanner assembly from the top of the copy machine for the primary movement (what will end up the Y movement). Of the tabletop scanners, only one used a linear shaft (others used molded plastic and pushed against the glass for support), so I'll be using that one for the secondary movement (X movement), with the extra stability from another linear shaft pulled from something else. I've started teaching myself to code Arduino, and by connecting an Arduino Uno to a pair of EasyStepper controllers, I was able to get the steppers to move individually (based on a standalone program, but being sent commands from the computer quite yet.

I plan on using the copy machine scanner as the base of it all. I'll be putting drawer slides (harvested from the copy machine) on either side to move along with the movement. I plan on cutting apart the smaller scanner so it consists of only the motor movement, belt, and linear shafts, as well as make the carriage smaller. This will all link up with the copy machine movement and rest on the drawer slides. There will be a big piece of flat metal (or something else? MDF?) as the print surface, located above the copy machine movement, but below the smaller scanner movement (about inline with the drawer slides). This will give me a rough cutting area of about 16"x12".

[The Laser Question]

This is pretty much as far as I've gotten in terms of general planning. The next big question, which I come to you for, is the laser itself. I should mention here that I have some experience with lasers. Not a ton, but I know enough to err on the side of caution. I've made laser pointers with a red DVD burner diode and a mag light housing, and I have a Wicked Arctic 1W laser (I know, I know). I've seen people make engravers with DVD lasers, but it can't cut through much and is really slow. I plan on going with a blue diode, unless someone here can convince me otherwise. Oh, and I also plan on building something into this where it will shade the beam while it's cutting so I won't need to use glasses all the time while it's cutting, but I still will use glasses whenever I'm operating it. I've been doing some research into blue diodes, cooling them, powering them, etc. I know the capabilities of something like this is limited, but I'd hopefully like to engrave plastic, maybe cut thin plastic, cut foam, paper, card stock, and cardboard, etc. I would also hope it could move at a decent speed and not take a half hour to do a small job. Does anyone here have much experience with cutting with blue diodes? I'm thinking something between a 1-3W laser. Is going from 1 up to 3 in this case worth it? Should I get a driver with it or assemble it myself, and would it be beneficial to pulse the beam? Any input, suggestions, or links (for purchase or simply as research) would help a lot.

I should mention that I wouldn't mind doing a small build for a battery powered pointer before making a wired in, higher powered version. Possibly a smaller .5-1W pointer I could build into a small host. I'd also like to get some better glasses to use with the laser cutter, especially since I know the WL glasses are crap (which is one of the reasons I hardly ever use the Arctic indoors), so some direction on this would be go too.

Another small question (if you guys would know) is should I add any kind of Z movement? I have a couple small rack and pinion movements connected to a tiny stepper, so I could get about 3" of Z movement if I wanted. Would this extra effort benefit me at all, or should I just forget about it? How much would I be changing the height of the laser or adjusting the focus?

I'm hoping this will be a good laser project, while trying to keep this project as inexpensive as possible. I know the laser is going to be the main cost in this, but since I've only spent about $40 on parts so far (for the Arduino and EasySteppers), hopefully I can keep the whole project under around $250.

Any and all advice would be greatly appreciated!

Last edited: