- Joined

- Nov 20, 2008

- Messages

- 4

- Points

- 0

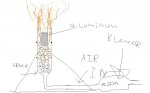

And... what are you trying to say? You have a crappy 700 degrees pot oven that you probably used to make war hammer figures. You might as well have been making rice crispy treats. Buy a heat sink they are relatively cheap and will save you the trouble of going to the hospital.