- Joined

- Aug 22, 2009

- Messages

- 404

- Points

- 0

hi all,

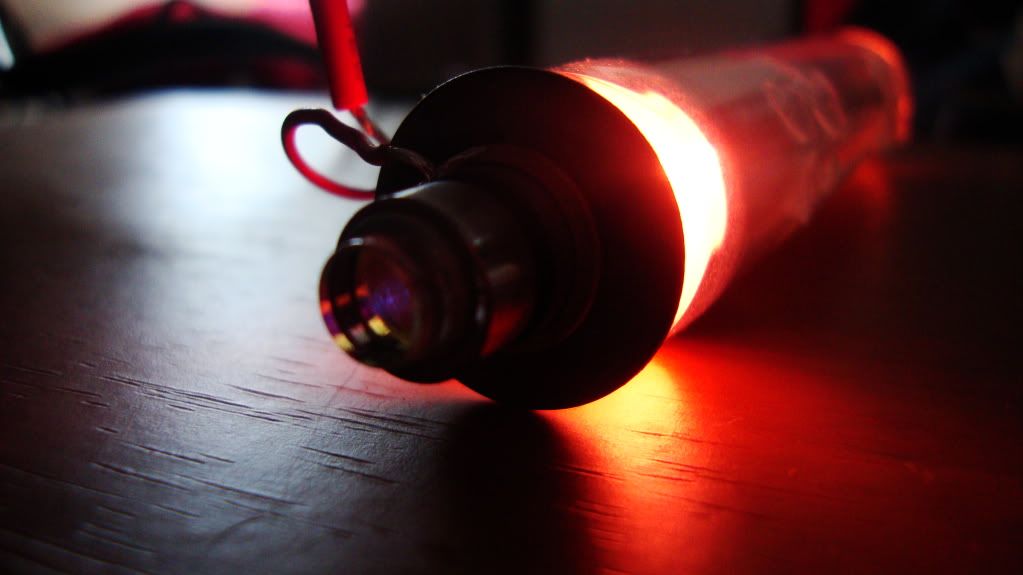

i have a HeNe laser i got off ebay for $25 w/ pwr supply i was wondering if there is any way of removing the outer tube thingy its in revealing the laser tube in all its laser tubey good ness

oh yeah i have pics!

i have a HeNe laser i got off ebay for $25 w/ pwr supply i was wondering if there is any way of removing the outer tube thingy its in revealing the laser tube in all its laser tubey good ness

oh yeah i have pics!