- Joined

- Nov 2, 2012

- Messages

- 626

- Points

- 43

Update #3: Fuse popping problem solved; waiting on parts. Still investigating stray voltage leaking to laser case.

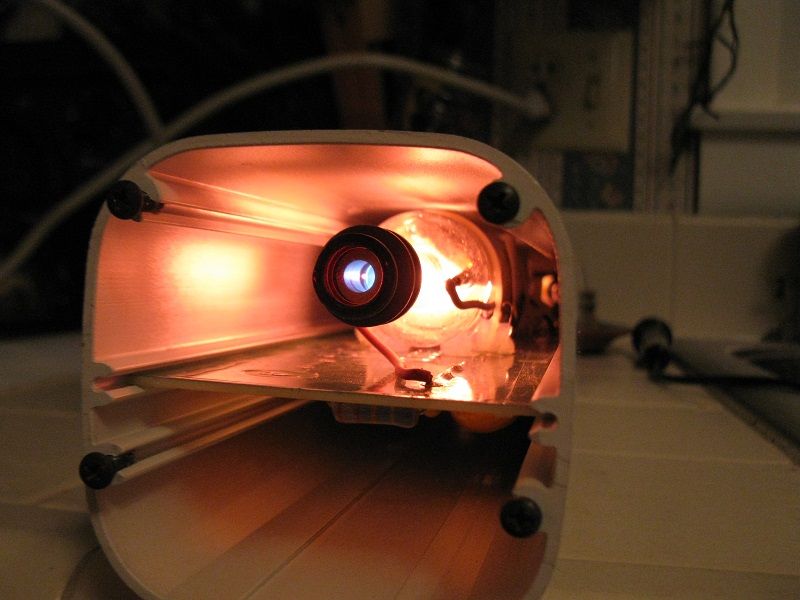

Update #2: Laser tube is confirmed working!

Update #1: It might not be the tube, turns out one of the components has a heatsink which is connected directly to the host. The board is otherwise loose inside the case. When the laser hit the floor the leads on that component broke. The component is clearly loose. Heading downstairs to warm up the soldering iron. Stay tuned!

This post concerns a non-working Metrologic HeNe laser, 632.8nm. No idea what model number or what the actual output was, there is no label on the outside indicating any of that. There's the usual safety sticker of course; class IIIa laser, according to that. Very, very old, 1980's I figure. This has got to be a really nice one; it has a video and audio input on the back.

I got the laser when I was in 11th grade, back in 1998. I was 17 at the time. This is the first laser I ever owned. I never did find out if the a/v modulation worked but it put out a typical TEM00 red beam.

Then, I broke it by accident. It fell off my bed and dropped a few feet onto a carpeted floor, and after that it never lased again. I'm not kidding when I say I'm klutzy and tend to drop things without warning, and this laser clearly paid the price for that. The memory of it is still crystal-clear and it's always sort of bothered me, in a way. I figured the tube was damaged and that it wasn't fixable, or at least that it was beyond anything I could do for it. Ebay didn't exist at that time and neither did LPF. I had no idea where to find a replacement tube, and I assumed it would have cost 100's of dollars anyway. So, I put the the laser away and it's sat in a box in my basement ever since, 15 years now.

Until today! Nowadays we have LPF and ebay, and between the two maybe I can bring this laser back to life. So, I pulled it from storage, opened it up carefully, and had a look to see if something might be done.

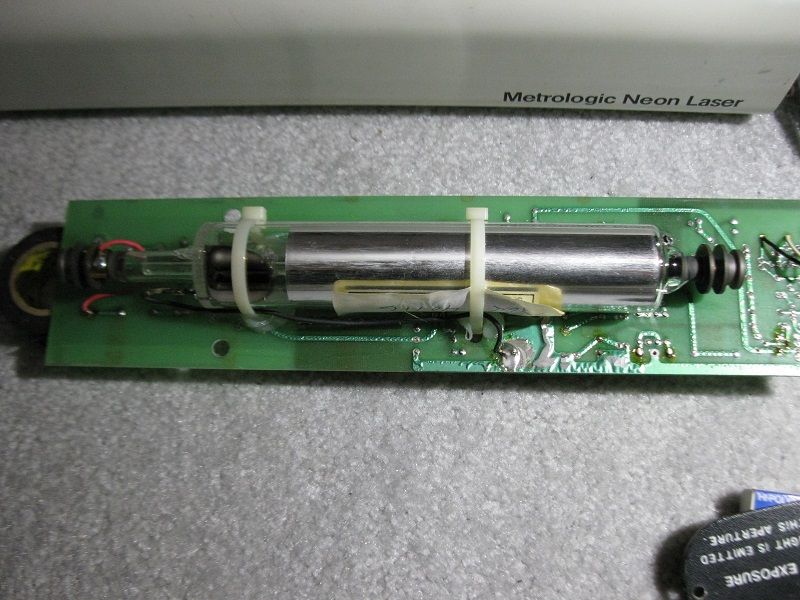

The power light comes on when I flip the switch, but the tube doesn't light up at all. Not even the pink plasma discharge. Nothing rattles around inside the tube. It's hard to see into the tube as there is a metal can covering most everything, but I'm pretty sure that the central bore tube is cracked. Never actually saw a HeNe tube in person until now but I'm pretty sure the bore tube is supposed to be a single piece of glass all the way through, and when I shine a laser into it (flashlight batteries are currently dead) it looks like the bore has a crack in it. Would that cause it to not light up at all though?

The board looks fine, can't imagine why it wouldn't be, so I'm going to cross my fingers and assume that that isn't the problem. I'm not sure how to test it for high voltage output since my multimeter only goes up to 1000 volts. No spark or anything after I unplugged it and shorted the HV leads, but maybe the caps have resistors across them to drain off unused charge. The ground lead broke off the board due to a really poor solder joint, but that's a trivial repair. Advice on how to test the board would definitely be appreciated.

What do you all think? Probably just killed the tube and all it needs is a new one, I hope?

Photos:

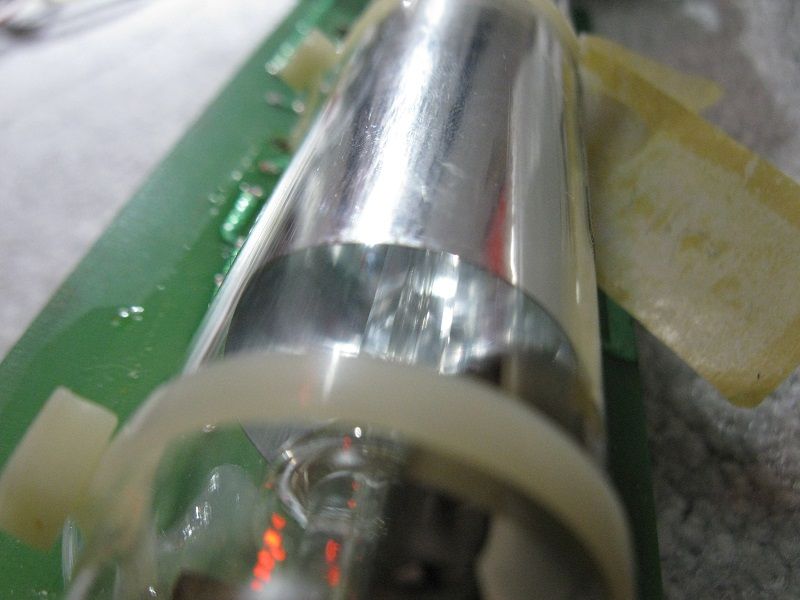

In the first two I tried to get a shot of what I think is the crack in the bore tube. The metal can covers up pretty much everything and the viewing angle is therefore awkward. The automatic focus wasn't cooperating much either:

Bore tube attempt #2:

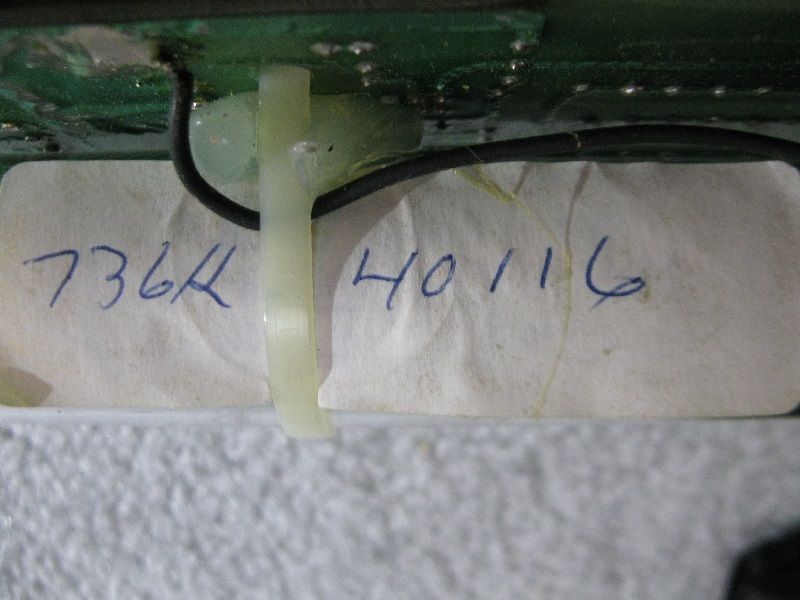

Tube serial number. It matches the number on the tube's actual label, which is hidden below this hand-written one:

The board, bottom side. Looks OK to me. Lots of pretty caps. Nothing missing or broken, except the ground lead on the right:

Top side of the board:

The back panel, with A/V jacks:

Aperture panel:

Closer look at the host/casing. Is it still called a host when it's a gas laser? White enameled aluminum:

Safety sticker, old and faded:

Last edited: