- Joined

- Feb 9, 2008

- Messages

- 152

- Points

- 18

I've been thinking about making this since I saw Daves 8X Burner. Of course I would like to make my own when I can afford it. I have a nice piece of titanium that I plan to use.

I have this green 20mW laser that I got from DX a while back(my favourite) and I really like its sturdiness and weight.

http://www.dealextreme.com/details.dx/sku.2511

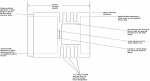

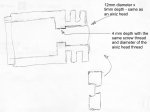

So I came up with this laser module head design that is one peice that will press fit onto the body of the above-mentioned pointer. Obviously it will require a Flexdrive to run off of a single CR2(maybe 2 in parellel for an 8X). Also if I am going to use an 8X diode, I'll be needing one of those 405-G1 lens assemblies.

If I had my own lathe, I would make a whole bunch of them and then maybe I could make some money.

Anyway, everyone is free to use the design and of course change it any way they see fit for their own custom laser.

If this design is close to any one elses design I appologize in advance. I have never seen a custom laser, aside from the pictures on this forum.

Also, if there is anyone out there willing to do the machining for me, it would be great if you could make a deal with me. I won`t have access to a lathe for a while.

Peace, Steve

P.S. Sorry about the Windows Paint cartoon drawing. That's all I have.

I have this green 20mW laser that I got from DX a while back(my favourite) and I really like its sturdiness and weight.

http://www.dealextreme.com/details.dx/sku.2511

So I came up with this laser module head design that is one peice that will press fit onto the body of the above-mentioned pointer. Obviously it will require a Flexdrive to run off of a single CR2(maybe 2 in parellel for an 8X). Also if I am going to use an 8X diode, I'll be needing one of those 405-G1 lens assemblies.

If I had my own lathe, I would make a whole bunch of them and then maybe I could make some money.

Anyway, everyone is free to use the design and of course change it any way they see fit for their own custom laser.

If this design is close to any one elses design I appologize in advance. I have never seen a custom laser, aside from the pictures on this forum.

Also, if there is anyone out there willing to do the machining for me, it would be great if you could make a deal with me. I won`t have access to a lathe for a while.

Peace, Steve

P.S. Sorry about the Windows Paint cartoon drawing. That's all I have.