- Joined

- Aug 25, 2010

- Messages

- 533

- Points

- 63

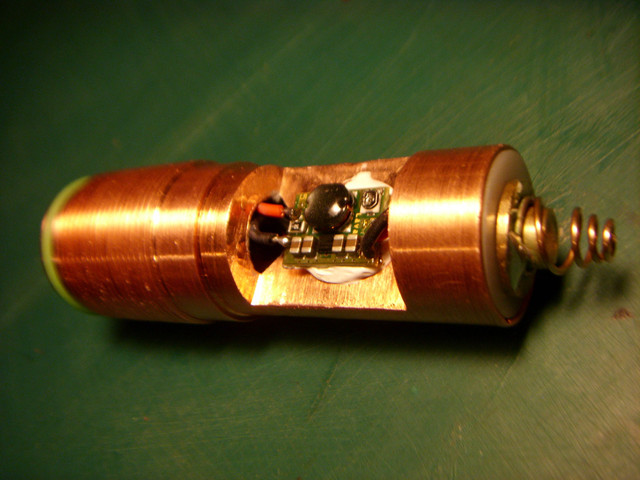

I have two Cypreus II copper heatsinks with a problem: the hole inside isn't depth enough to put inside a diode with back aluminum heatsink like this:

The hole diameter is about 12.1 mm, but only for a lenght of 25 mm, after that the diameter become a little bit smaller. Usually the total lenght of the diode+small copper heatsink+aluminum heatsink is 30mm, so I need a guy with a suitable equipment that will modify for me that hole. Of course I need that the original diameter of 12.1 is preserved, and no damage will be done in the external threaded part.

This is the first issue to be corrected, but I have to correct another one:

I have a Zaser modified head (bigger with one extra fin) with an hole of 12.1 mm. This hole was black anodized as the rest of the head. I need that someone remove the anozidation from the hole with a reamer or similar tool. The diameter of the hole must be as close as possible to the original dimension. Also, this is a polished finished item, so no damage will be done around the surface.

I will pay every cost involved.

Please help me, since I have a lot of project ready to be completed, but first I must resolve those issues as soon as possible.

Thanks in advance.

The hole diameter is about 12.1 mm, but only for a lenght of 25 mm, after that the diameter become a little bit smaller. Usually the total lenght of the diode+small copper heatsink+aluminum heatsink is 30mm, so I need a guy with a suitable equipment that will modify for me that hole. Of course I need that the original diameter of 12.1 is preserved, and no damage will be done in the external threaded part.

This is the first issue to be corrected, but I have to correct another one:

I have a Zaser modified head (bigger with one extra fin) with an hole of 12.1 mm. This hole was black anodized as the rest of the head. I need that someone remove the anozidation from the hole with a reamer or similar tool. The diameter of the hole must be as close as possible to the original dimension. Also, this is a polished finished item, so no damage will be done around the surface.

I will pay every cost involved.

Please help me, since I have a lot of project ready to be completed, but first I must resolve those issues as soon as possible.

Thanks in advance.

Last edited: