- Joined

- Aug 25, 2010

- Messages

- 533

- Points

- 63

I'm starting to order to a big company in Italy some new lenses for my five Laserglow beam expanders.

All the lenses of my expanders were scratched and full of imperfections from origin, so I decide to buy new sets built much better of the originals.

I do not understand why a serious company like Laserglow insists to sell very expensive expanders with the lenses ruined at factory.

The last expander that I bought about one week ago show the same defects of all the others expanders.

I asked always to check the lenses before to ship them with the same results ...

Take a look of the horrid surface of the last lenses that I have bought last week:

If You think that this expander costs 349 dollars plus courier plus duty taxes,

it is a totally unacceptable issue!

So now I need some infos about the diode frequency to make an exact coating to apply to the new raw lenses.

I have a NDB7875 9mm 445nm diode @2W, a NDB7A75 3.5W 445nm diode

@5W and a Hercules with a 532nm DPSS diode.

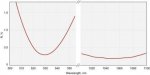

To obtain the best coating performance I need two parameters: the central frequency and the range before and after the central frequency.

So there is anyone that can help me to find those specs?

For example: the 532nm DPSS diode is not overpushed, so the central frequency is really 532. It is enough to make a +-5% gap?

For the 445nm ones I have some doubts: in fact overpushing the diode surely will increase the frequency, but how much? It is important for me to know the central frequency of the two 445nm diodes to make a correct bell centered at that frequency.

Please remind that a closer bell centered to a wrong mid frequency can cause a big loss of power, but also a thicker bell can cause a noticeable loss of power due to the increased reflection area of the lens.

All the lenses of my expanders were scratched and full of imperfections from origin, so I decide to buy new sets built much better of the originals.

I do not understand why a serious company like Laserglow insists to sell very expensive expanders with the lenses ruined at factory.

The last expander that I bought about one week ago show the same defects of all the others expanders.

I asked always to check the lenses before to ship them with the same results ...

Take a look of the horrid surface of the last lenses that I have bought last week:

If You think that this expander costs 349 dollars plus courier plus duty taxes,

it is a totally unacceptable issue!

So now I need some infos about the diode frequency to make an exact coating to apply to the new raw lenses.

I have a NDB7875 9mm 445nm diode @2W, a NDB7A75 3.5W 445nm diode

@5W and a Hercules with a 532nm DPSS diode.

To obtain the best coating performance I need two parameters: the central frequency and the range before and after the central frequency.

So there is anyone that can help me to find those specs?

For example: the 532nm DPSS diode is not overpushed, so the central frequency is really 532. It is enough to make a +-5% gap?

For the 445nm ones I have some doubts: in fact overpushing the diode surely will increase the frequency, but how much? It is important for me to know the central frequency of the two 445nm diodes to make a correct bell centered at that frequency.

Please remind that a closer bell centered to a wrong mid frequency can cause a big loss of power, but also a thicker bell can cause a noticeable loss of power due to the increased reflection area of the lens.

Last edited: