ryansoh3

0

- Joined

- Feb 23, 2012

- Messages

- 1,282

- Points

- 0

Hi LPF, I was thinking of designing a heatsink and came upon a question.

I'm using 9mm diodes in a threaded module. Is it better to:

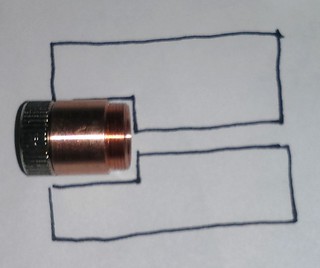

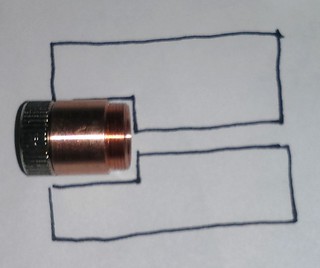

Use only the copper module and have the back of the diode contact the heatsink. This will leave an air gap where the module is threaded:

Use the aluminum back, but the back of the diode will not be heatsunk.

Would love to hear your guys' thoughts.

I'm using 9mm diodes in a threaded module. Is it better to:

Use only the copper module and have the back of the diode contact the heatsink. This will leave an air gap where the module is threaded:

Use the aluminum back, but the back of the diode will not be heatsunk.

Would love to hear your guys' thoughts.