bdgreenb

0

- Joined

- Jul 20, 2011

- Messages

- 723

- Points

- 28

In your sig put the words between the color tags:

your colored text here [color]

your colored text here [color]

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

We don't have engraving capabilities, but we could probably stamp it on the chassis, which is basically the same.

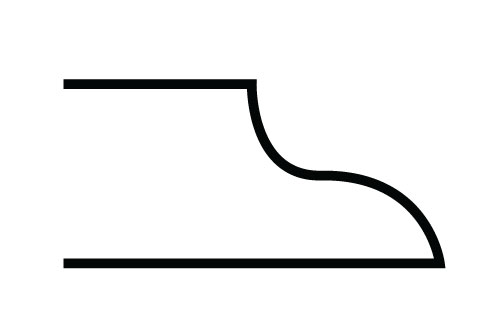

ok what is your price for what i have.. i think it will be worth it judging your other work i've seen. The edges , Lamb's tongues, just needed to be done with a hand held belt sander and vice and have a rough texture for grip and coolingWith all these add-ons you want, these is no way you are getting this made for $500-$600. Especially if you want me to do special edge-profiling machining with special end-mills. Machining aluminum isn't the same as woodworking.

ok what is your price for what i have.. i think it will be worth it judging your other work ive seen